Vehicle door frame structure

A vehicle and door frame technology, which is applied in the field of vehicle door frame structure, can solve problems such as easy rusting, and achieve the effects of improving waterproof performance, easy joining, and ensuring waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

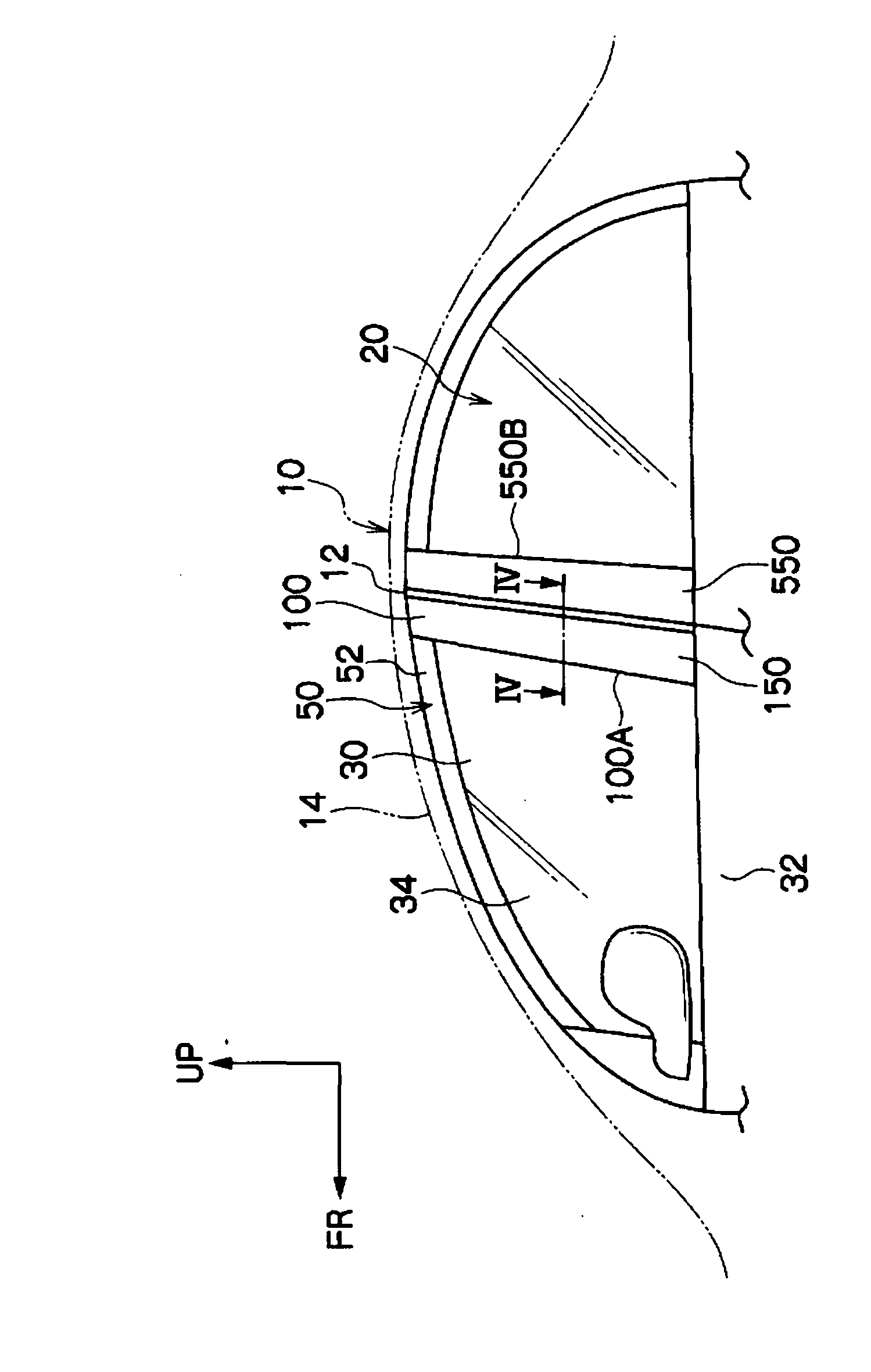

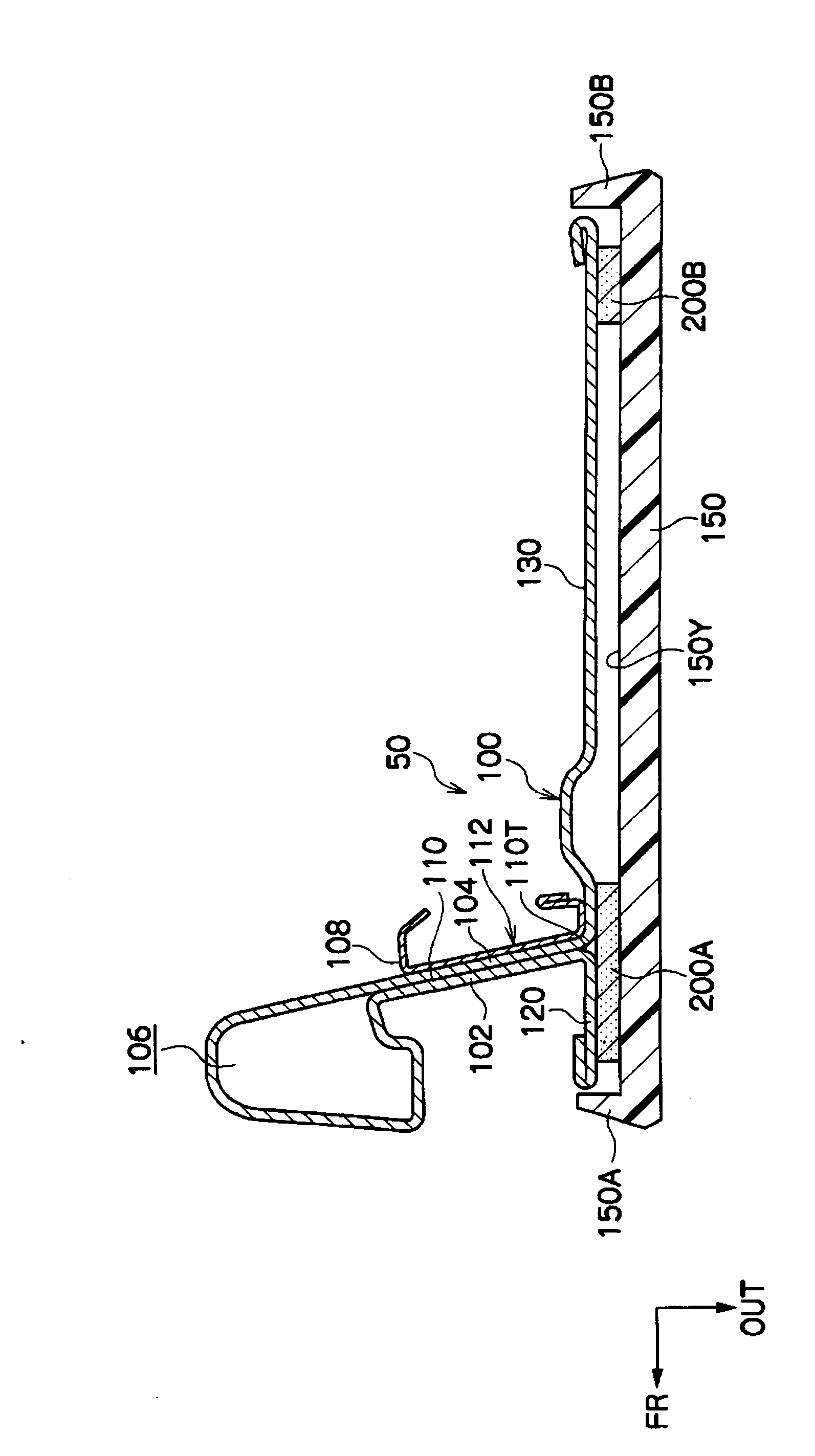

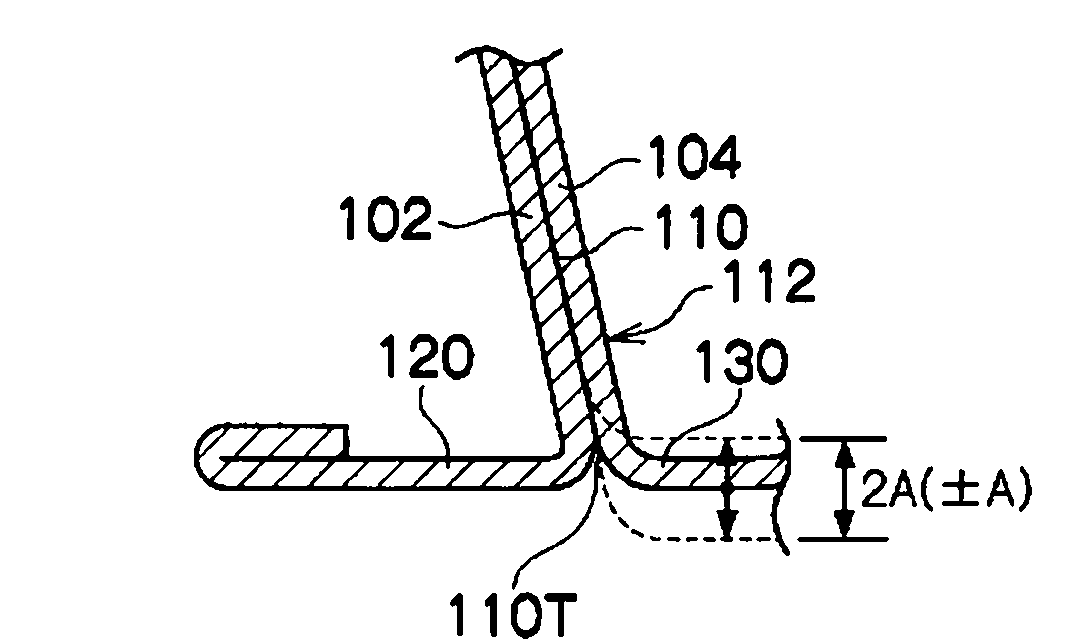

[0047] to combine figure 1 and figure 2 The first embodiment of the door frame structure in the present invention will be described. figure 1 It is a side view showing a door frame of a side door of a vehicle to which the door frame structure of the first embodiment is applied. figure 2 is along figure 1 Horizontal sectional view of line IV-IV. In addition, arrow UP in the drawings indicates the vehicle upward direction, arrow FR indicates the vehicle front direction, and arrow OUT indicates the vehicle width direction outward direction.

[0048] Such as figure 1 As shown, a front side door 30 , a rear side door 20 , and a center pillar (B-pillar) 12 extending in the vertical direction of the vehicle between the front side door 30 and the rear side door 20 are disposed on the side of the vehicle 10 .

[0049] On the front side door 30 of the vehicle 10 , a door frame 50 is integrally joined to an upper portion of the door body 32 . The door frame 50 constitutes a win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com