Sine wave inverting power supply

A sine wave, inverter technology, applied in the field of power electronic technology inverter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

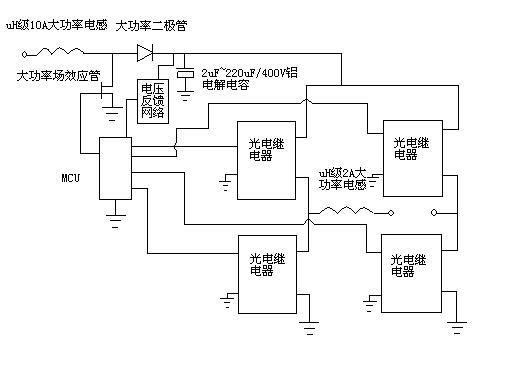

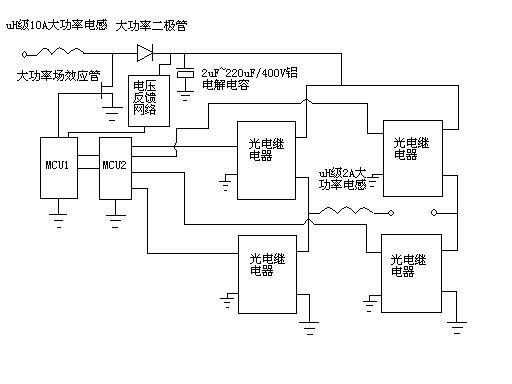

[0005] The main components of the sine wave inverter are uH-class 10A high-power inductors, high-power FETs, power diodes, MCU, uH-class 2A high-power inductors, voltage feedback networks, 2uF~220uF / 400V aluminum electrolytic capacitors and photoelectric relays. Such as figure 1 shown. The uH grade 10A high-power inductor is connected to the high-power FET, the high-power FET is connected to the power diode, the high-power FET is connected to the MCU, and the power diode is connected to the 2uF~220uF / 400V aluminum electrolytic capacitor. Each photoelectric relay of the full bridge composed of MCU and photoelectric relays is connected, the full bridge composed of photoelectric relays is connected with 2uF~220uF / 400V aluminum electrolytic capacitors, the output end of the full bridge composed of uH class 2A high-power inductors and photoelectric relays One end is connected, the voltage feedback network is connected to the MCU, the voltage feedback network is connected to the 2u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com