Method for manufacturing serial uniwafer integrated multi-junction thin film solar cell

A solar cell, monolithic integration technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of heavy solar cells, inability to meet high-voltage applications, and inability to meet applications, and achieve high-efficiency photoelectric conversion. , with market competitiveness, the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below will further illustrate the present invention with embodiment in conjunction with accompanying drawing:

[0033] The tandem monolithic integrated multi-junction thin-film solar cell of this embodiment is mainly composed of the following parts: 1. Substrate, 2. Isolation layer, 3. Lower contact layer, 4. Tunnel junction, 5. Multi-junction p-n junction Structure, 6. Top contact layer, 7. Passivation insulating layer, 8. Electrical connection layer.

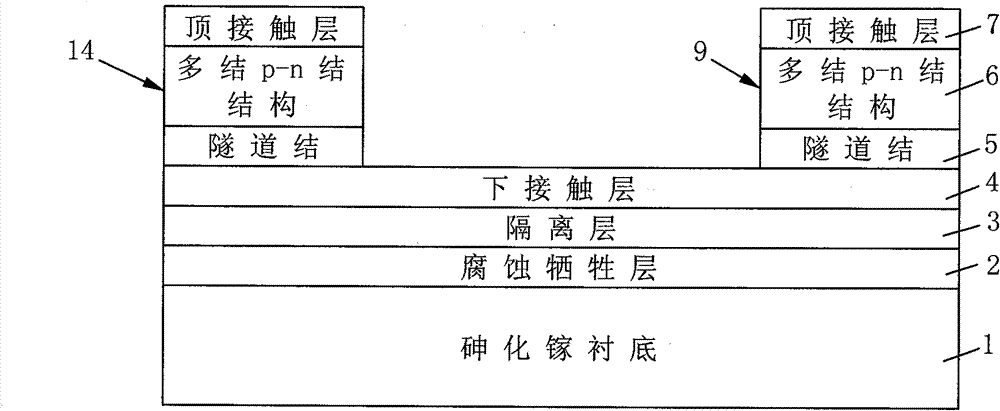

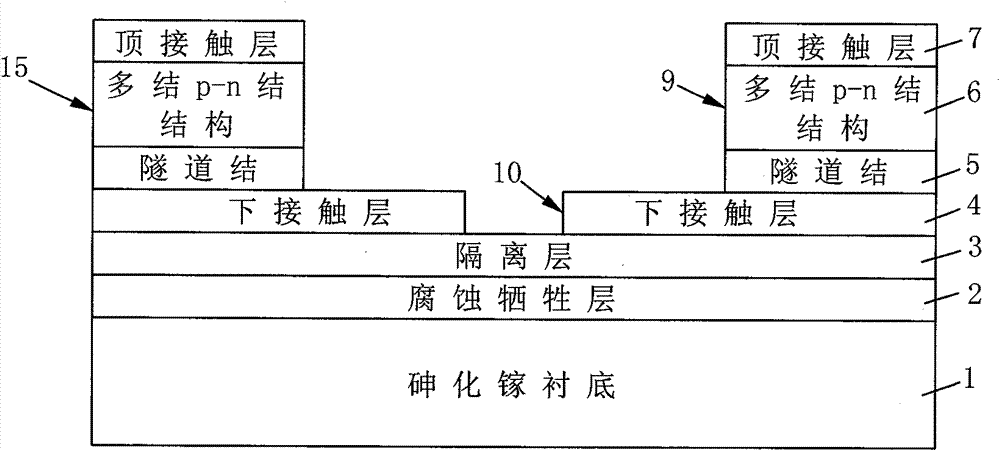

[0034] The manufacturing method of this tandem monolithic integrated multi-junction thin film solar cell mainly includes the following steps:

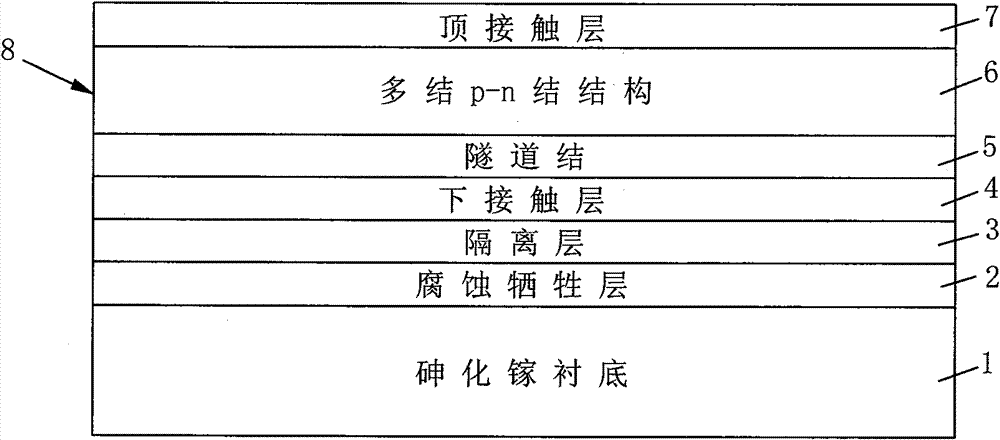

[0035] 1. If figure 1 As shown, an etching sacrificial layer 2 is grown on a gallium arsenide (GaAs) substrate 1 by molecular beam epitaxy or metal organic chemical vapor deposition, and the etching sacrificial layer 2 is made of aluminum arsenide (AlAs) material. At the same time, a multi-junction solar cell epitaxial material 8 is deposited on the etching sacrificial layer 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com