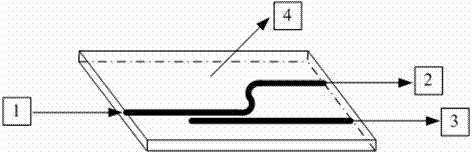

Y-shaped porous hollowed slab terahertz wave polarizing beam splitter

A polarization beam splitter and terahertz technology, applied in the coupling direction of optical waveguide, can solve the problems of low transmittance, complex structure and difficult manufacture of polarization beam splitting, and achieve small size, high beam splitting rate and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

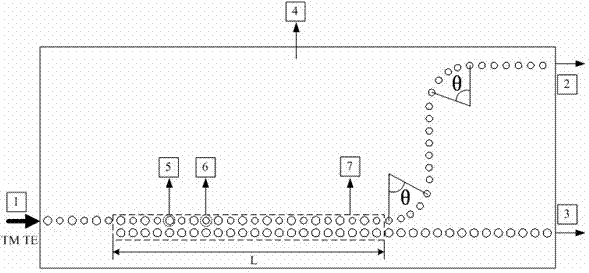

Embodiment 1

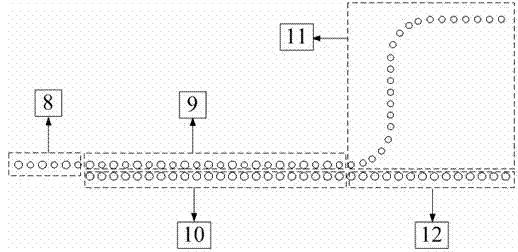

[0019] The hole spacing a of the Y-shaped hole-shaped flat plate terahertz wave polarizing beam splitter is 40 μm, the coupling spacing d is 24 μm, the radius R of the large-hole hollow 5 is 9 μm, and the radius r of the small-hole hollow 6 is 7.2 μm. The material of the flat polarizer 4 is gallium arsenide material with a refractive index of 3.25. The coupling length L is 60 μm, and the adjacent hole-shaped hollows arranged in a curved line are bent in the transmission direction where the first signal output terminal 2 is located, and the bending angle θ thereof is 90 degrees. The TE wave and TM wave transmittance curves of the first signal output end 2 of the Y-shaped hollow plate terahertz wave polarization beam splitter are as follows: Image 6 As shown, the maximum transmittance of TE wave in the 0.2~1.0THz frequency band is 98%, and the minimum transmittance of TM wave is 2%. The TM wave and TE wave transmittance curves of the second signal output end 3 of the Y-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com