Method for measuring viscosity of dynamic fluid by using bending vibration

A technology of bending vibration and fluid viscosity, applied in measurement devices, flow characteristics, instruments, etc., can solve the problem that real-time online measurement cannot be realized, and achieve the effect of real-time online measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

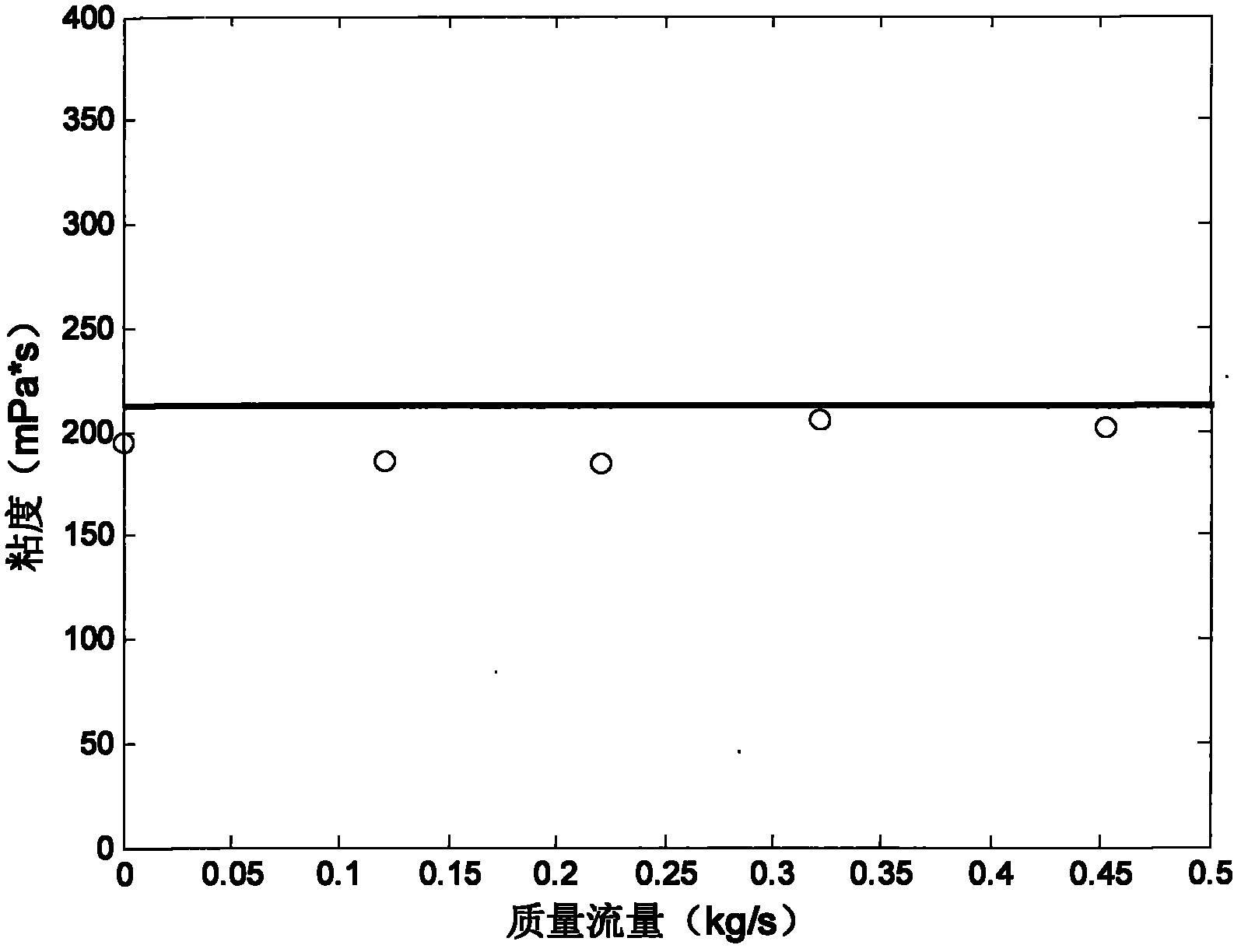

Embodiment 1

[0028] ① Continuously inject air into the vibrating tube and fill it with air. The controller controls the vibrating tube to perform constant-amplitude bending vibration with an amplitude A. Measure the output power P of the controller when the vibrating tube vibrates. 0 and the resonant frequency f of the vibrating tube 0 ;

[0029] ② Continuously inject the known dynamic viscosity η into the vibrating tube 1 The fluid inside the vibrating tube is filled with the fluid, and the inlet and outlet of the vibrating tube are respectively equipped with a solenoid valve. Close the solenoid valve so that the fluid in the tube does not have an axial flow velocity along the direction of the pipeline. Bending vibration with constant amplitude, measure the output power P of the controller 1 and the resonant frequency f of the vibrating tube 1 ;

[0030] ③Calculation of fluid viscosity factor K s ;

[0031] K s = η...

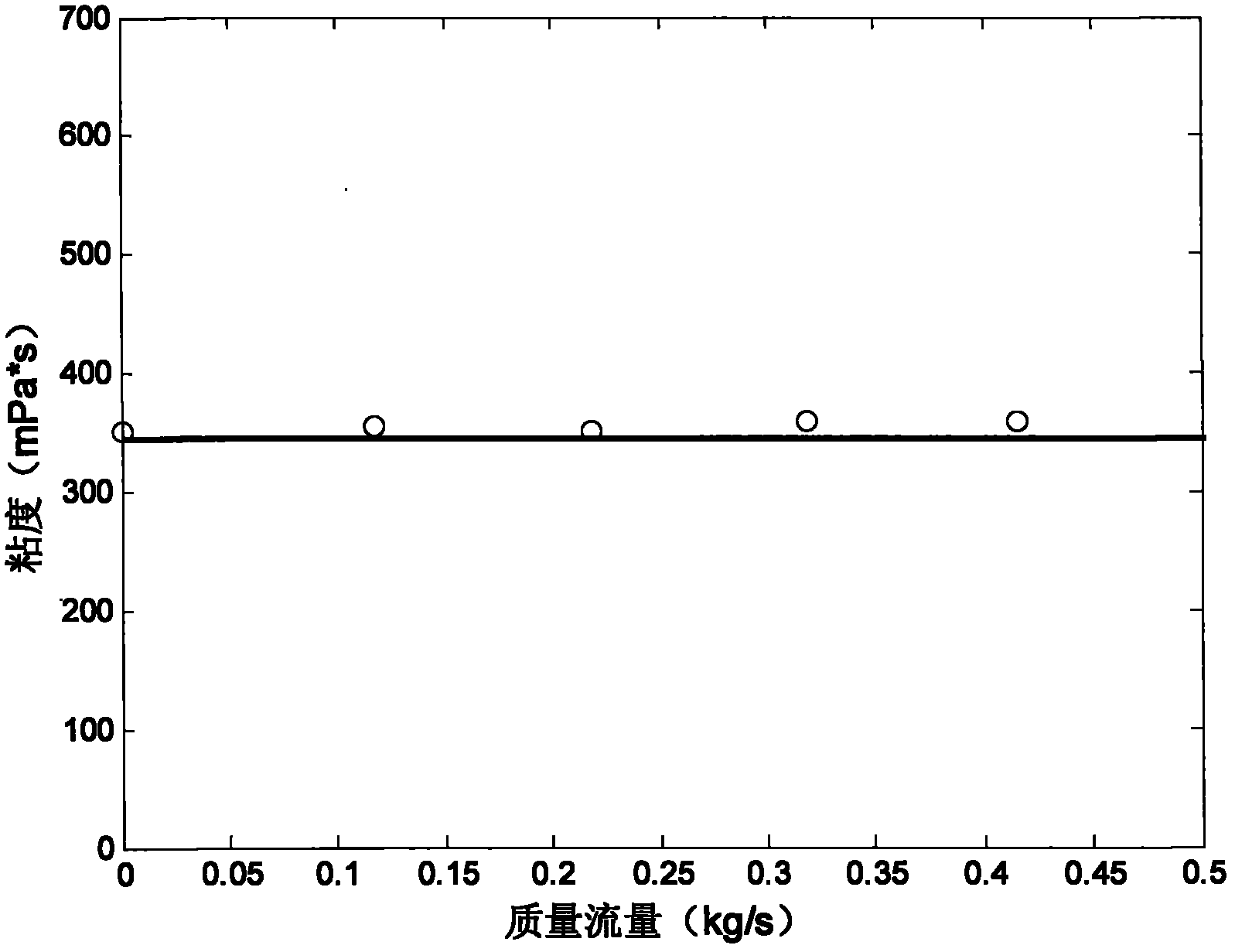

Embodiment 2

[0039] ① Continuously inject air into the vibrating tube and fill it with air, the controller controls the vibrating tube to perform constant amplitude bending vibration with amplitude B, and measure the output power P of the controller when the vibrating tube vibrates 0 and the resonant frequency f of the vibrating tube 0 ;

[0040] ② Continuously inject the known dynamic viscosity η into the vibrating tube 1 The fluid inside is filled with the fluid, the inlet and outlet of the vibrating tube are respectively provided with a solenoid valve, the solenoid valve is closed so that the fluid in the tube does not have an axial flow velocity along the direction of the pipeline, and the controller controls the vibrating tube to proceed with the vibration amplitude B Bending vibration with constant amplitude, measure the output power P of the controller 1 and the resonant frequency f of the vibrating tube 1 ;

[0041] ③Calculation of fluid viscosity factor K s ;

[0042] ...

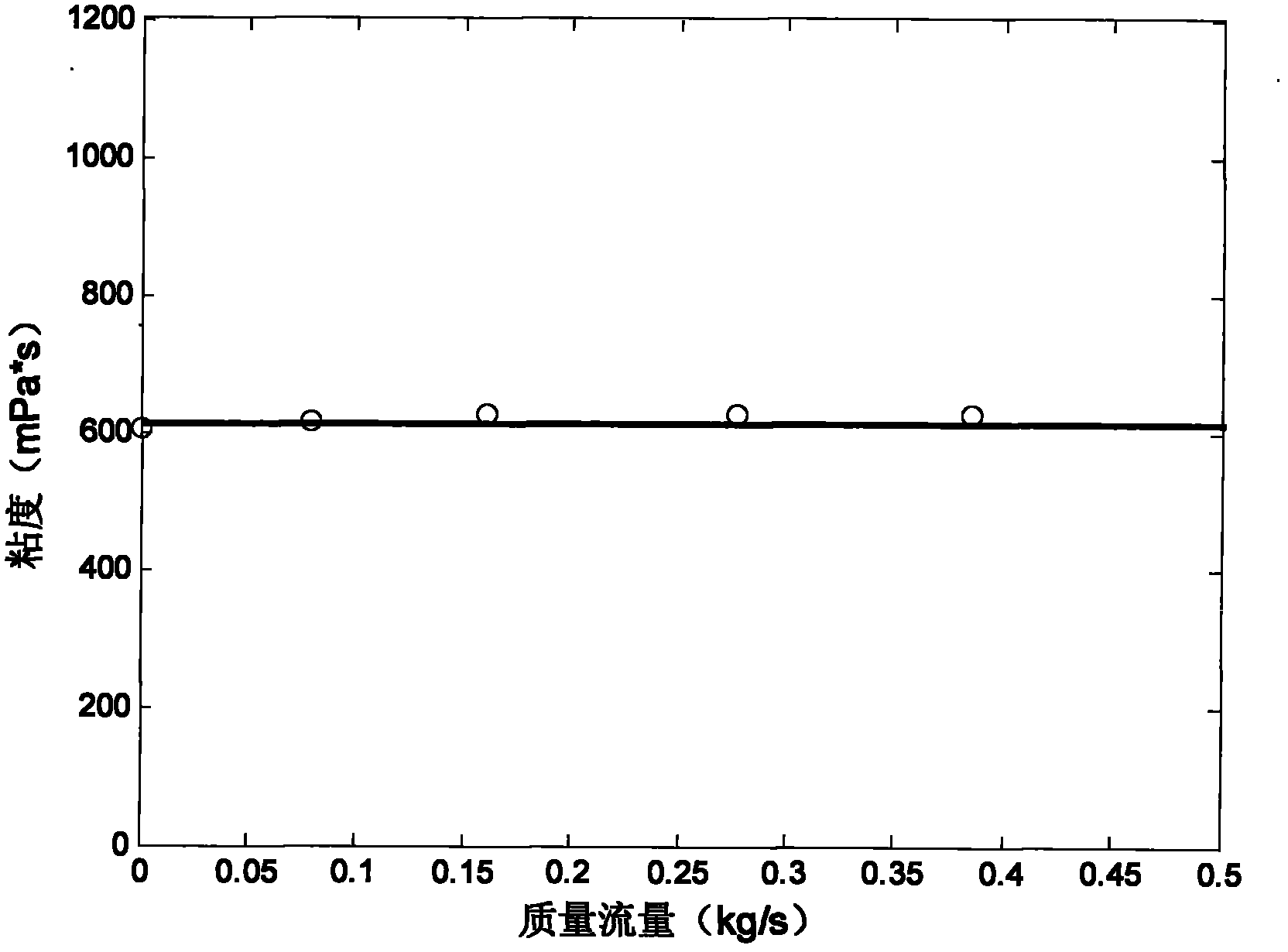

Embodiment 3

[0050] ① Continuously inject air into the vibrating tube and fill it with air, the controller controls the vibrating tube to perform constant amplitude bending vibration with amplitude C, and measure the output power P of the controller when the vibrating tube vibrates 0 and the resonant frequency f of the vibrating tube0 ;

[0051] ② Continuously inject the known dynamic viscosity η into the vibrating tube 1 The fluid in the tube is filled with the fluid, the inlet and outlet of the vibrating tube are respectively provided with a solenoid valve, the solenoid valve is closed, so that the fluid in the tube does not have an axial flow velocity along the direction of the tube, and the controller controls the vibrating tube to proceed with the vibration amplitude C Bending vibration with constant amplitude, measure the output power P of the controller 1 and the resonant frequency f of the vibrating tube 1 ;

[0052] ③Calculation of fluid viscosity factor K s ;

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com