Jet stirrer for mechanical stirring and desulfurizing of molten iron

A mechanical stirring and air-jet technology, which is applied to mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of desulfurization slag retention and sticking, achieve enhanced stability, maintain slow rise, shrink The effect of forming volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

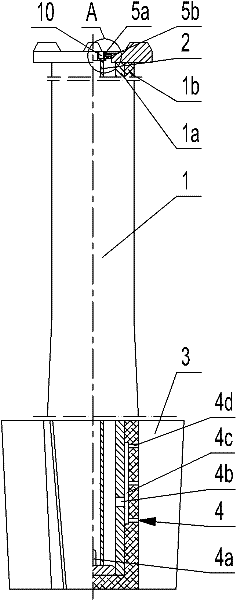

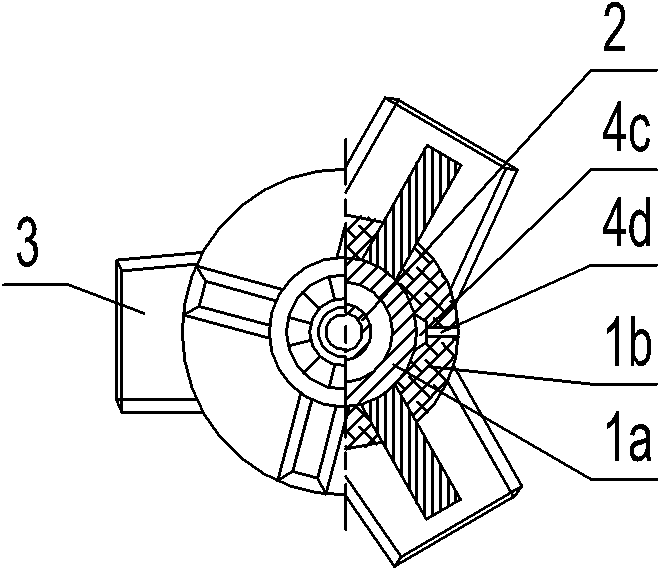

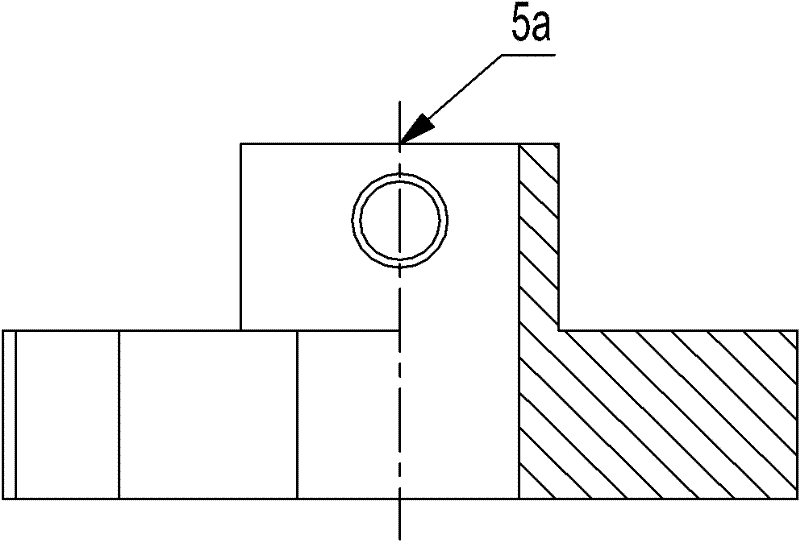

[0026] Such as figure 1 and figure 2 As shown, the jet agitator for mechanical stirring and desulfurization of molten iron of the present invention includes a rotating shaft 1 and a stirring blade 3 arranged at the lower end of the rotating shaft 1 and uniformly arranged along its circumference. The stirring blade 3 can be 3 to 6 pieces, rotating around Shaft 1 is evenly distributed circumferentially. The rotating shaft 1 is composed of a metal hollow shaft 1a and a refractory working lining 1b compounded outside the metal hollow shaft 1a, and an air-cooled pipe 2 is arranged in the inner cavity of the metal hollow shaft 1a. The lower end of the rotating shaft 1 is provided with an air injection channel 4 communicating with the air cooling tube 2 , and the air injection channel 4 is located between adjacent stirring blades 3 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com