Modified polyurethane hot melt adhesive using plants as raw materials and production process thereof

A polyurethane hot-melt adhesive and plant raw material technology, applied in polyurea/polyurethane adhesives, adhesives, starch-derived adhesives, etc., can solve the problems of high cost of polyurethane, waste of leftovers, environmental pollution, etc., and achieve price reduction , avoid environmental pollution, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

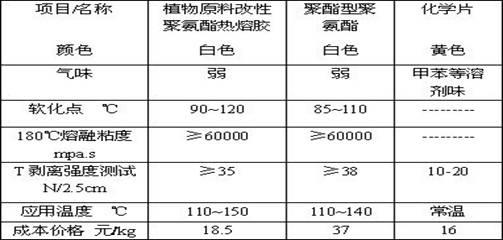

Embodiment 1

[0029] Example 1: plant raw material modified polyurethane hot melt adhesive, including the following components: composite modified starch 35%, vegetable tackifying resin 13%, toughening agent 2%, compatibilizer 10%, ultraviolet light stabilizer 2 %, polyurethane 35%, coupling agent 0.5%, antioxidant 1.5%, smooth agent 1%, and described polyurethane is polyester polyurethane.

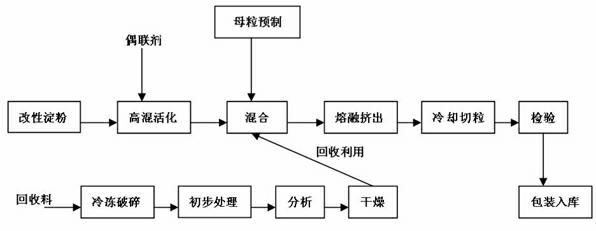

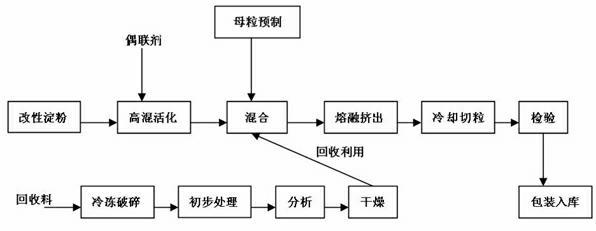

[0030] refer to figure 1 It is the route map of the plant raw material modified polyurethane hot melt adhesive production process of the present invention, and the plant raw material modified polyurethane hot melt adhesive production process comprises the following steps:

[0031] A. Activation of compound modified starch: Wheat modified starch and corn modified starch are mixed in a ratio of 3:1, and then additives are added for high-speed mixing and activation; the modification method is to use difunctional or multifunctional reagents to make the starch larger. Molecules form cross-links;

[0032] ...

Embodiment 2

[0040] Embodiment 2: plant raw material modified polyurethane hot melt adhesive, including the following components, the mass percentage of each component is: plant-based tackifying resin 10%, toughening agent 3%, compatibilizer 7%, ultraviolet light stabilizer 0.6% %, 40% polyurethane, 0.5% coupling agent, 2% antioxidant, 0.5% slip agent, the others are composite modified starch, and the polyurethane is polyester polyurethane.

[0041] refer to figure 1 It is the route map of the plant raw material modified polyurethane hot melt adhesive production process of the present invention, and the plant raw material modified polyurethane hot melt adhesive production process comprises the following steps:

[0042] A. Activation of compound modified starch: Wheat modified starch and corn modified starch are mixed in a ratio of 3:1, and then additives are added for high-speed mixing and activation; the modification method is to use difunctional or multifunctional reagents to make the st...

Embodiment 3

[0051] Embodiment 3: The plant raw material modified polyurethane hot melt adhesive comprises the following components, and the mass percentage of each component is: 30% of plant-based tackifying resin, 10% of toughening agent, 15% of compatibilizer, and 2.6% of ultraviolet light stabilizer %, 21% polyurethane, 0.5% coupling agent, 1.5% antioxidant, 0.5% slip agent, the others are composite modified starch, and the polyurethane is polyester polyurethane.

[0052] refer to figure 1 It is the route map of the plant raw material modified polyurethane hot melt adhesive production process of the present invention, and the plant raw material modified polyurethane hot melt adhesive production process comprises the following steps:

[0053] A. Activation of compound modified starch: Wheat modified starch and corn modified starch are mixed in a ratio of 3:1, and then additives are added for high-speed mixing and activation; the modification method is to use difunctional or multifunctio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com