Penetrable regeneration paint for asphalt pavement and preparation method of penetrable regeneration paint

A technology of asphalt pavement and asphalt rejuvenator, applied in the direction of coating, etc., can solve the problems of inconsistent expansion rate and shrinkage rate, low cost performance, cumbersome process, etc., and achieve the effect of recovery performance, high cost performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

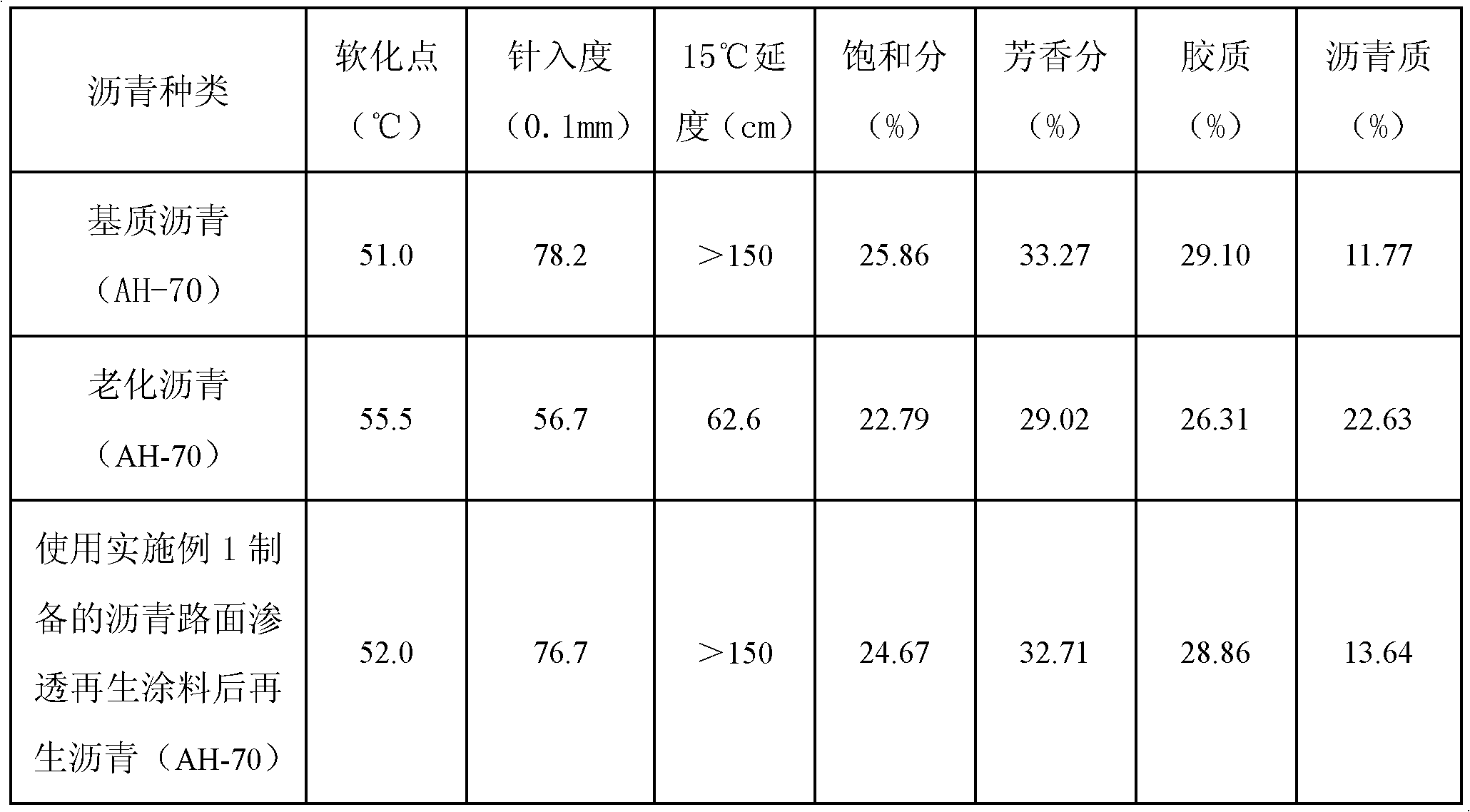

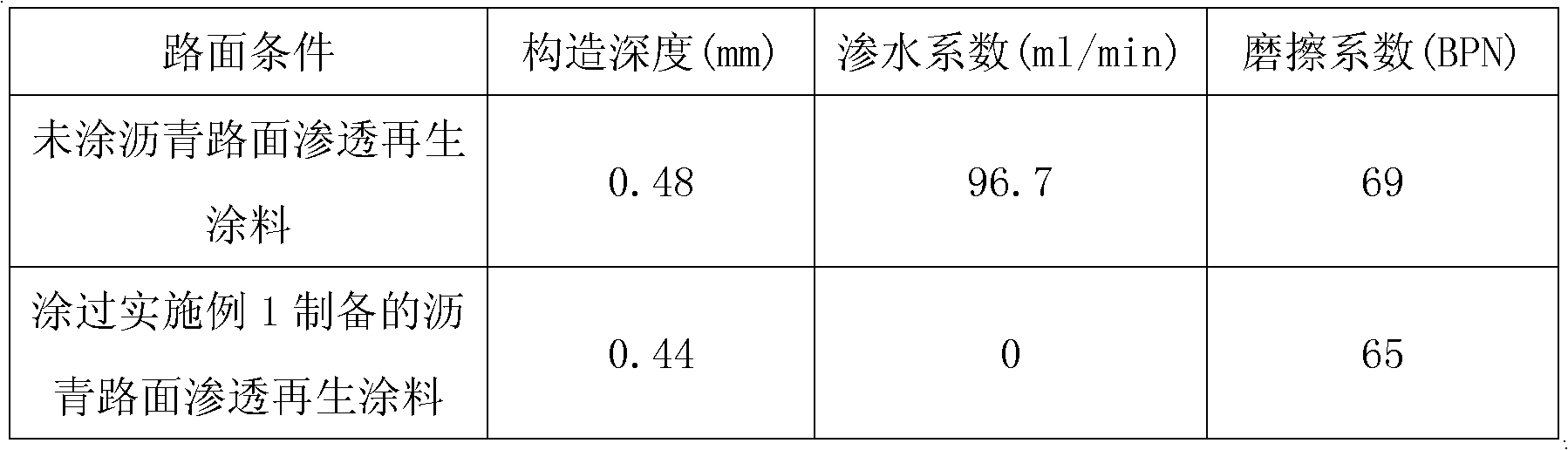

Embodiment 1

[0020] Raw materials: 420Kg No. 104 acrylic resin, 50Kg fast penetrating agent T, 60Kg furfural extraction oil, 360Kg toluene, 110Kg coal tar;

[0021] The above raw materials are operated according to the following steps: add coal tar and toluene to the reaction kettle under stirring conditions, heat up to 60°C after stirring for 8 minutes, add No. 104 acrylic resin, and add rapid penetrant T and furfural to extract the oil after stirring for 8 minutes. After continuing to stir for 30 minutes, cool down to room temperature, and the obtained liquid mixture is the asphalt pavement penetration regeneration paint.

Embodiment 2

[0023] Raw materials: 300Kg No. 105 acrylic resin, 90Kg penetrant JFC-M, 80Kg furfural oil, 330Kg toluene, 200Kg coal tar;

[0024] The above raw materials are operated according to the following steps: Add coal tar and toluene into the reaction kettle under stirring conditions, heat up to 70°C after stirring for 10 minutes, add No. 105 acrylic resin, and add penetrant JFC-M and furfural to extract the oil , continue to stir for 30 minutes, then cool to room temperature, and the resulting liquid mixture is the asphalt pavement penetration regeneration paint.

Embodiment 3

[0026] Raw materials: 350Kg No. 2080 acrylic resin, 30Kg fast penetrating agent T, 30Kg penetrating agent JFC-E, 20Kg furfural extraction oil, 200Kg kerosene, 200Kg phenyl glycidyl ether No. 690, 100Kg coal tar;

[0027] The above raw materials are operated according to the following steps: Add coal tar, kerosene, and phenyl glycidyl ether No. 690 into the reaction kettle under stirring conditions, stir for 15 minutes and then raise the temperature to 80°C, add No. 2080 acrylic resin, and stir for another 15 minutes. Penetrant T, penetrant JFC-E, and furfural extract the oil, continue to stir for 30 minutes, and then cool to room temperature. The resulting liquid mixture is the asphalt pavement infiltration regeneration coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com