Recycling repairing method for cement concrete pavement

A technology of cement concrete and cement, which is applied to cohesive pavement paved on site, roads, roads, etc., which can solve the problems of affecting road safety, long maintenance period, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

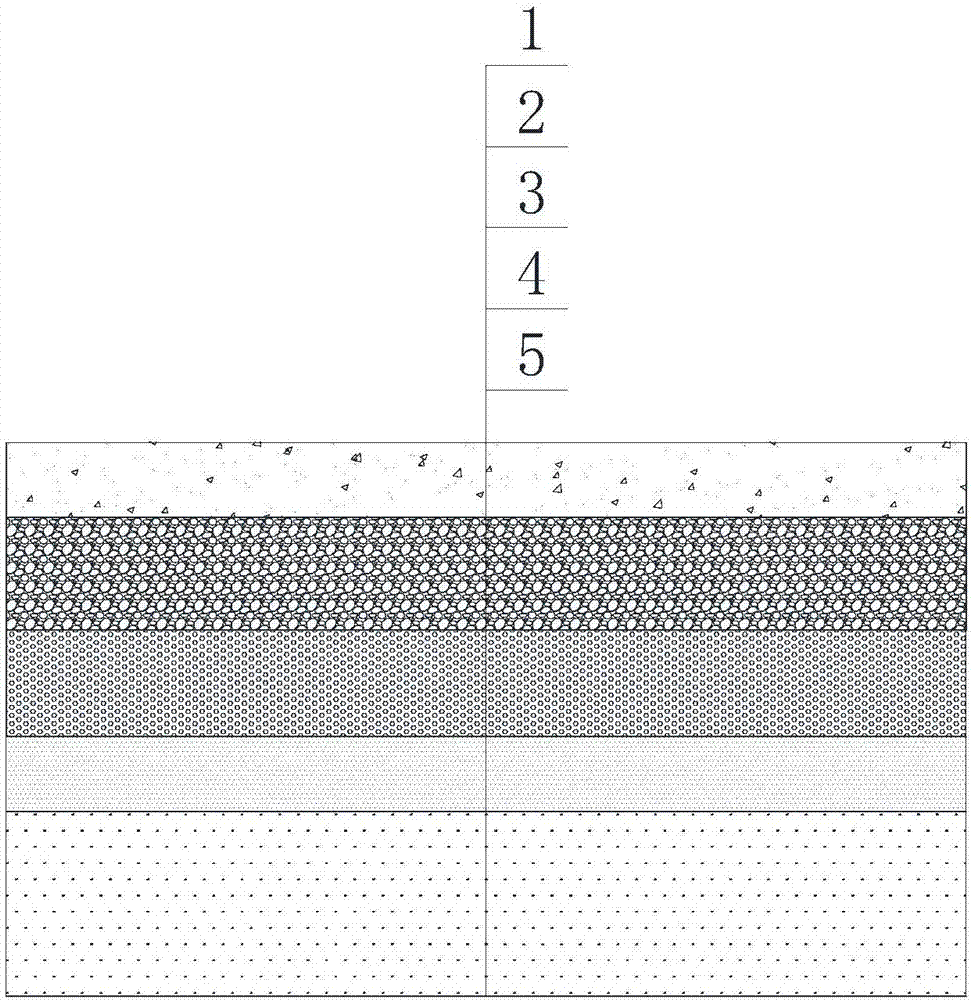

[0020] Construction preparation: Select the slabs with severe pavement breakage, use the hook machine or gun machine to break, and break the old concrete slabs into old concrete blocks within 30cm for later use.

[0021] Subgrade treatment: Refill or overturn the weak foundation, clean the bottom thoroughly, and the degree of compaction of the subgrade after treatment should not be lower than 95%.

[0022] Sand cushion construction: Evenly spread a 1cm-thick sand cushion on the treated foundation, and the sand cushion should preferably use river sand with a specification of medium sand.

[0023] Construction of stabilized crushed stone subbase: choose 15-25cm stones and place them evenly on the base surface, with the big side facing down and the small side facing up. : medium sand) to fill the gap between stones.

[0024] Construction of graded crushed stone base: Roll cement blocks over 20cm into crushed stones with a maximum nominal particle size of 5cm, mix them with co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Maximum nominal particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com