Transfer machine and flocking removing and drying system with same

A technology of a transfer machine and a rotating motor, applied in the field of transfer machines, can solve the problems of low labor efficiency of manual handling, difficult to guarantee product quality, affecting flocking quality, etc., so as to achieve a simple and compact overall structure, product quality assurance, and reduction of fluff. Damaged or detached effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

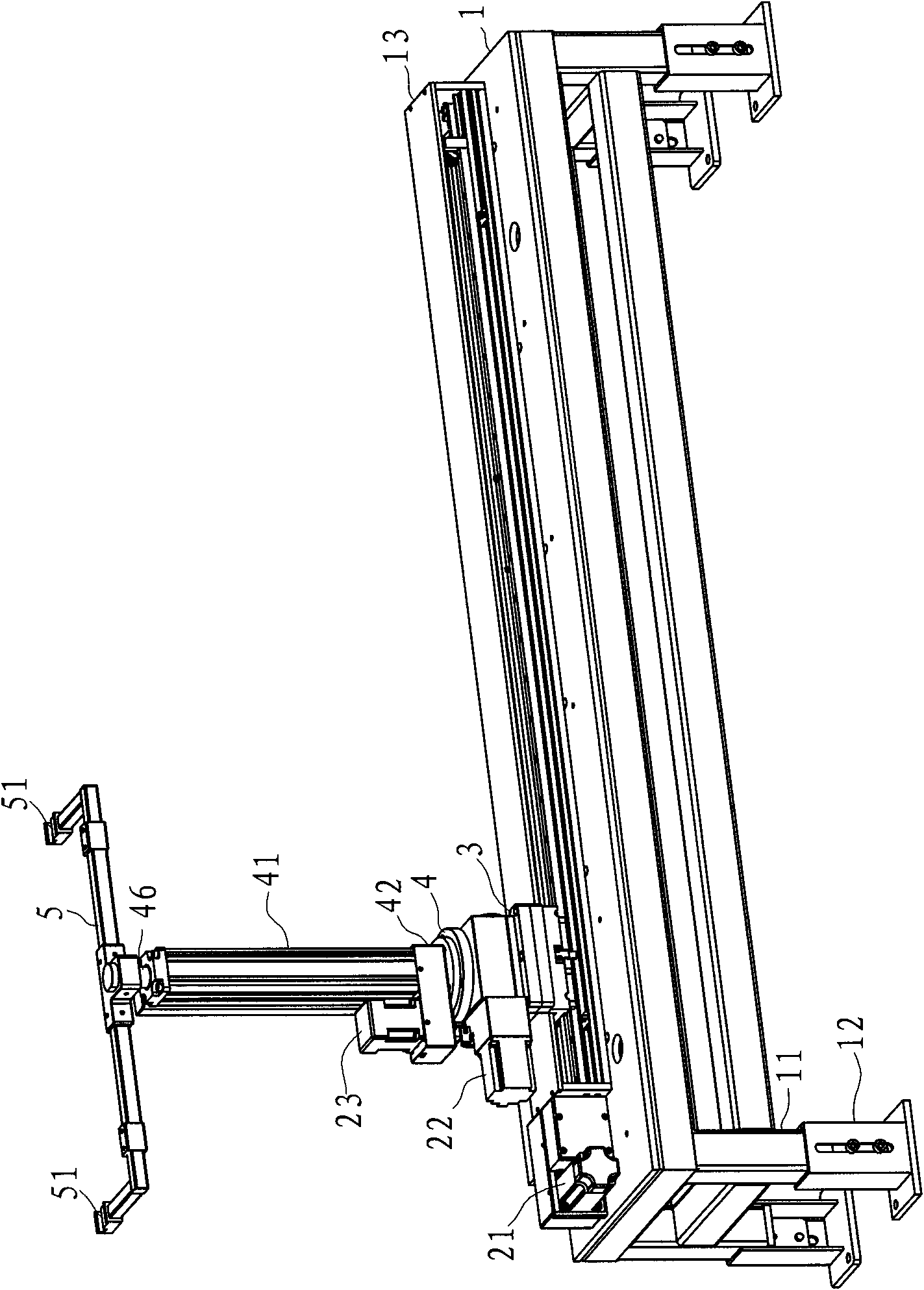

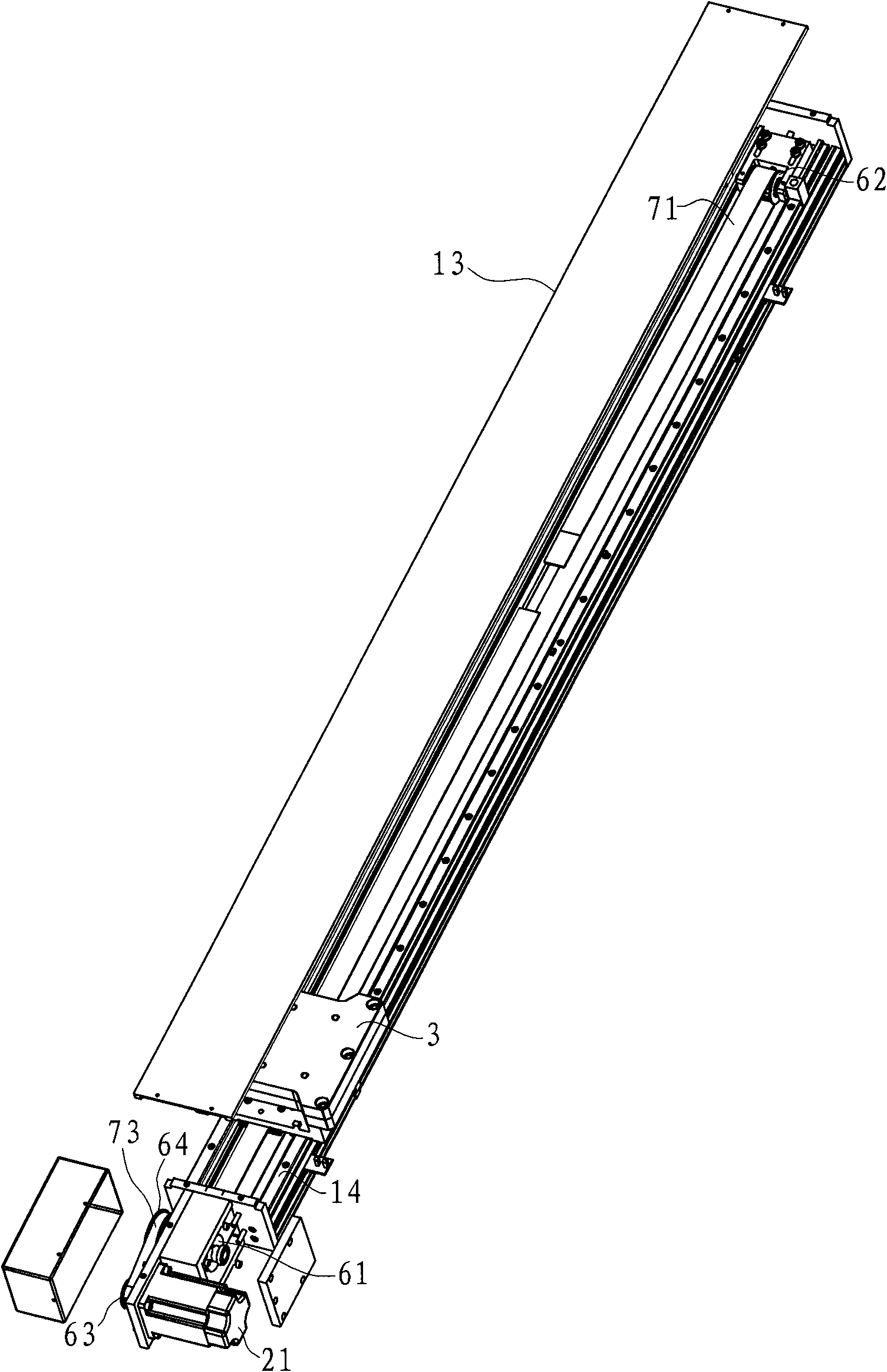

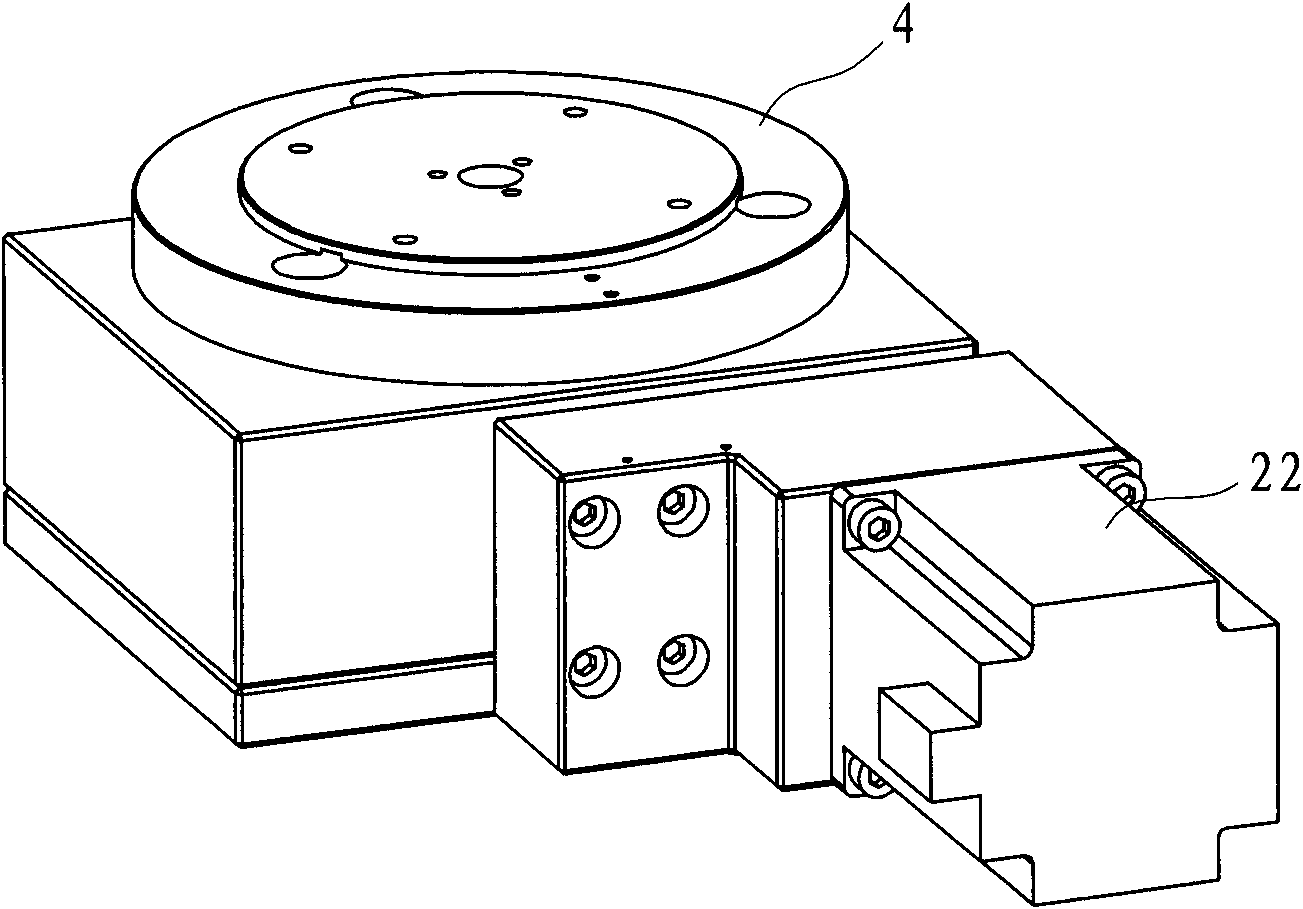

[0038] like figure 1 and figure 2 As shown in the figure, the transfer machine in this embodiment can transfer the internal water cutting and flocking operation for automobile doors from the dehairing machine to the drying tunnel, and it includes a base 1, a horizontal motor 21, a second pulley 62, and a first synchronous belt 71. , Slider 3 , rotating motor 22 , tray 4 , lifting motor 23 , screw 47 , second timing belt 72 , lifting shaft 47 and mechanical claw 5 .

[0039] The lower end surface of the base 1 is provided with four supporting feet 11, each of which is sleeved in the angle iron 12, and can be extended and retracted by bolts. The upper end surface of the base 1 has a guide rail 14 along the length direction of the first pulley 61 , and the bottom end of the slider 3 is formed with a guide groove (not marked in the figure) for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com