Forming equipment of extruding strip of plastic-steel winding tube

A technology for plastic-steel winding pipe and extruding strip, applied in the field of extrusion molding, can solve the problems of unfavorable strip heat conduction, strip deformation, surface unevenness, etc., and achieve the effect of avoiding deformation and surface unevenness and improving cooling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

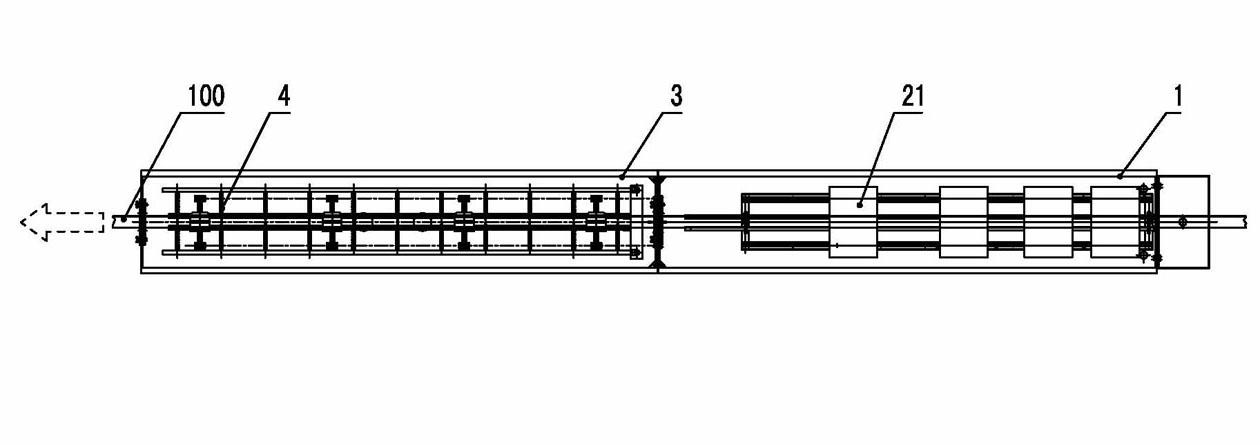

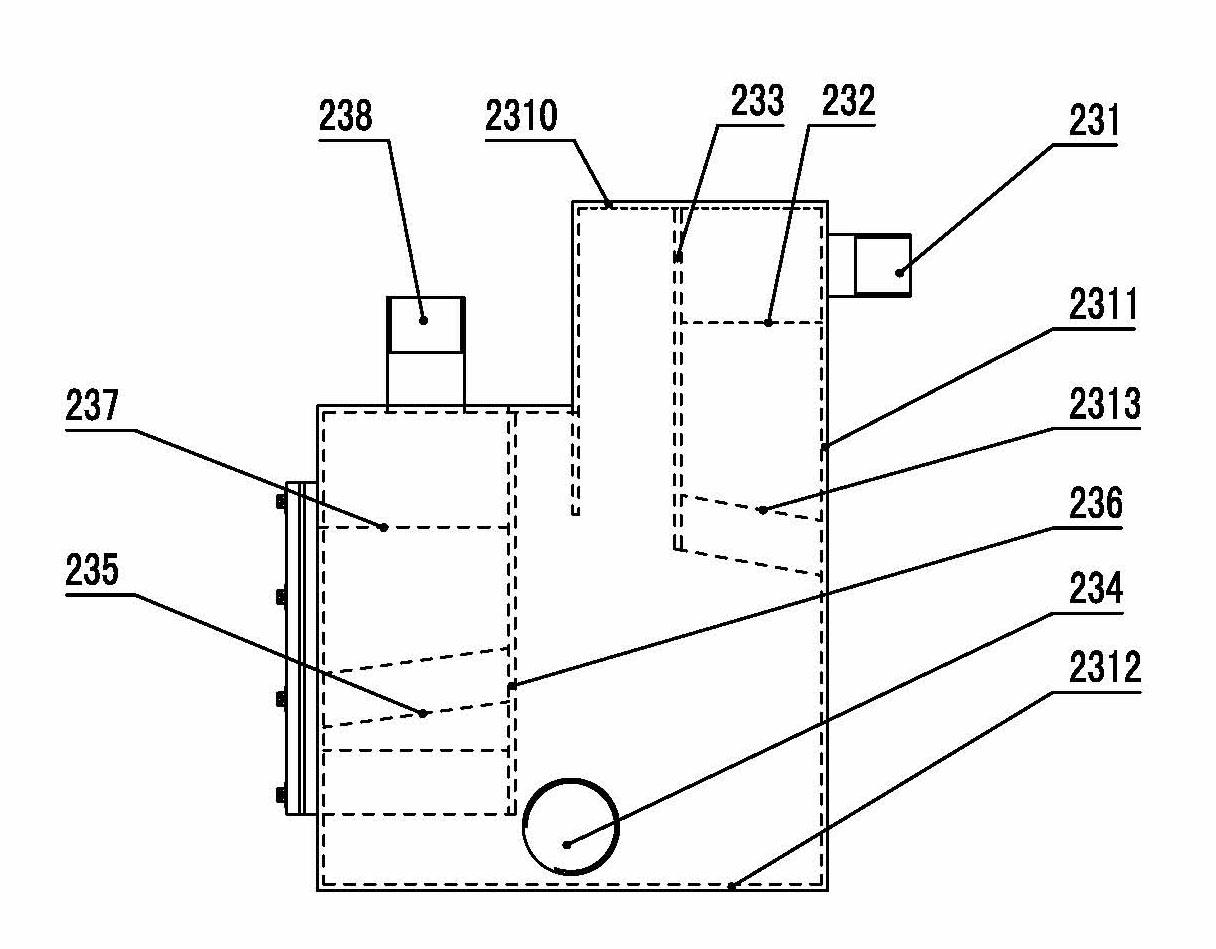

[0026] Figure 1 to Figure 10 The reference numerals in the drawing are: front water tank 1; vacuum setting mold 21; cooling integrated rack 22; vacuum gauge 221; input port 222; The second partition 232; the first partition 233; the first groove 2331; the drain 234; the fourth partition 235; the arc opening 2351; the third partition 236; the second groove 2361; The fifth partition plate 237; the exhaust port 238; the sixth partition plate 239; the cover plate 2310; the side plate 2311; the bottom plate 2312; the seventh partition plate 2313; Negative pressure safety valve 27; observation window 28; rear water tank 3; spray device 4;

[0027] like figure 1 Shown, a plastic-steel coiled pipe extruded strip molding equipment, including a front tank 1 and a rear tank 3, the front tank 1 is provided with a vacuum setting mold 21, the rear tank 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com