Injection molding method and injection molding device

A technology for injection molding and mounting bodies, which is applied in the field of injection molding devices, can solve the problems of reduced mold durability, increased cost, and increased manufacturing difficulty, and achieves improved durability, cost suppression, and low manufacturing difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

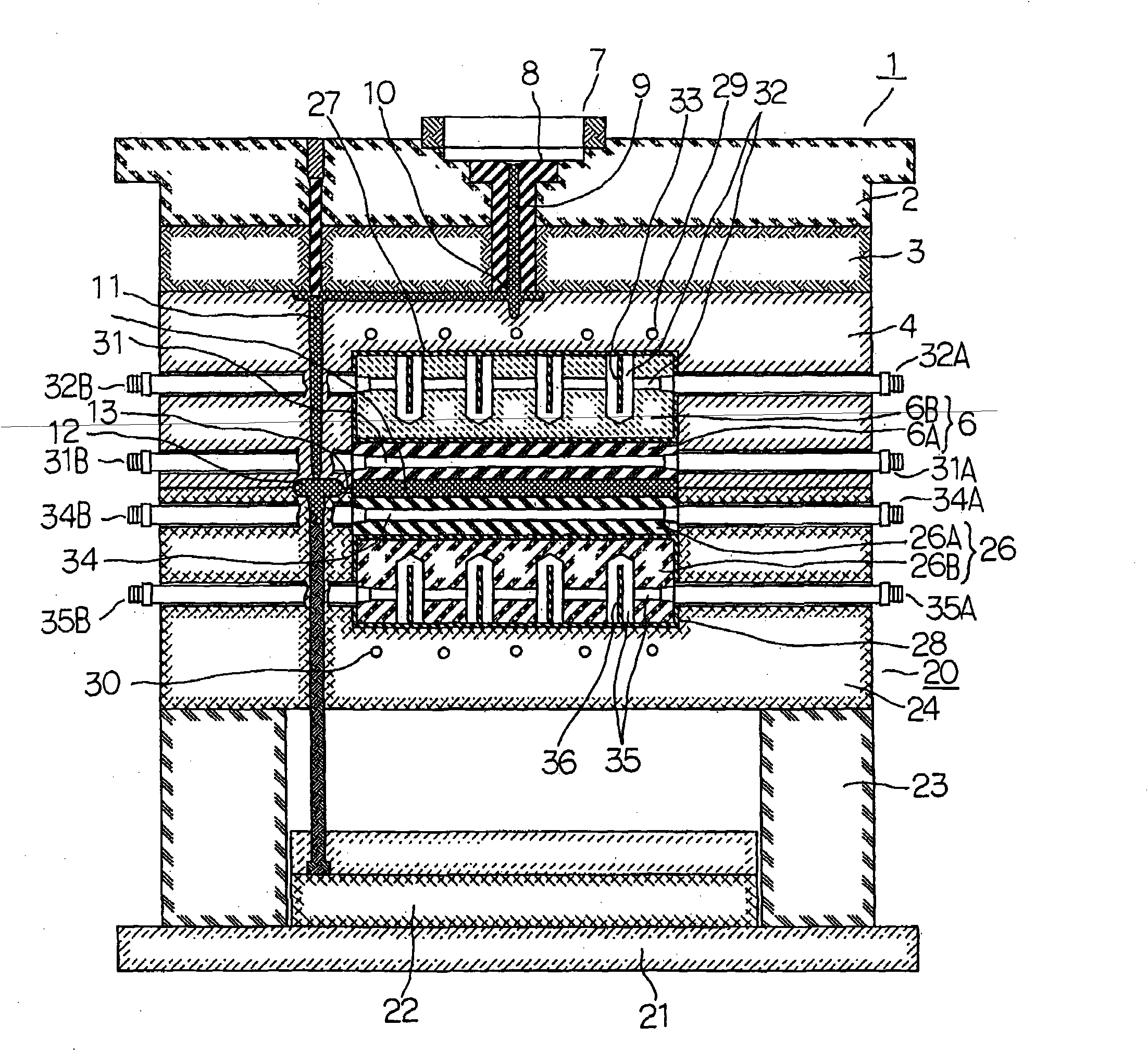

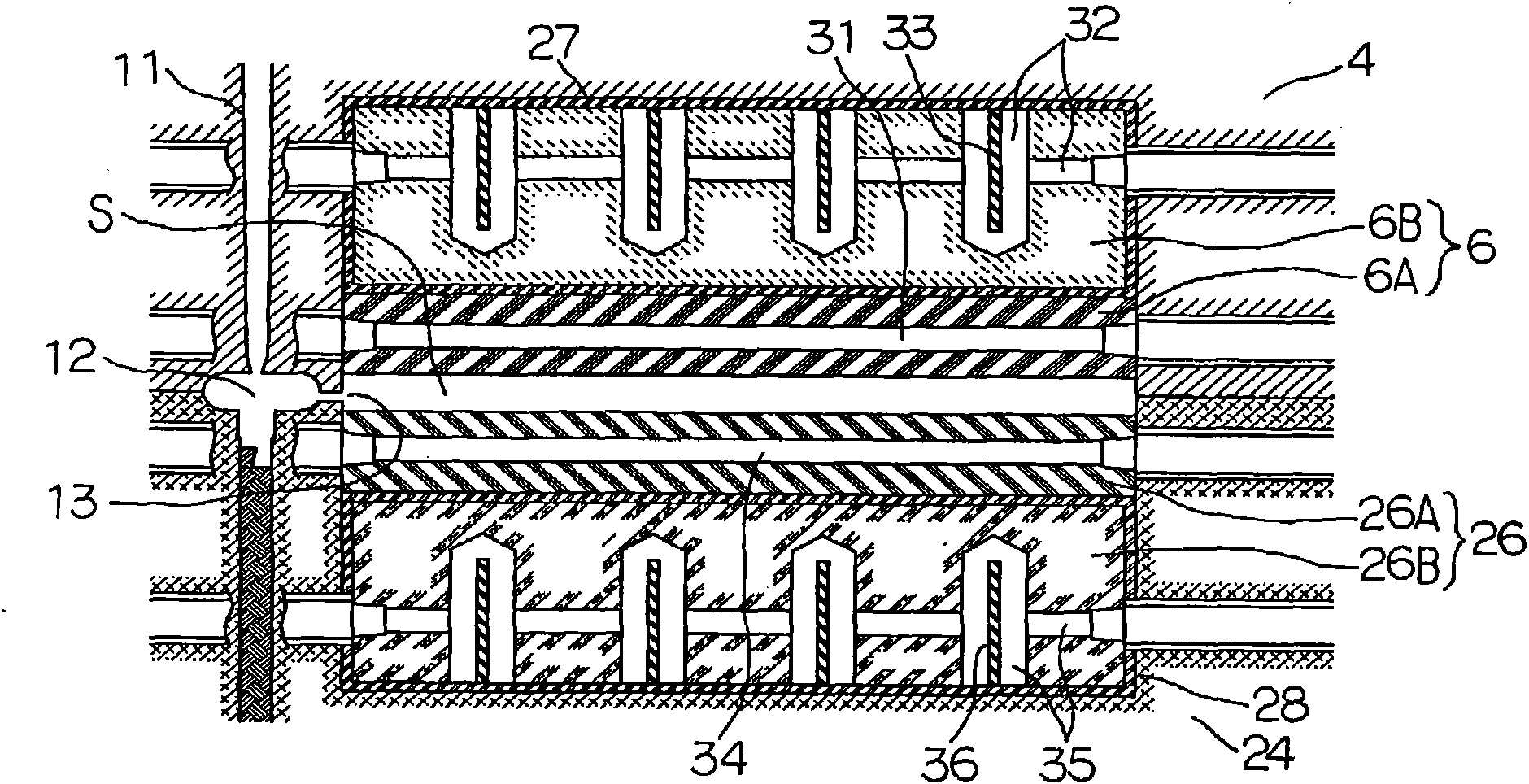

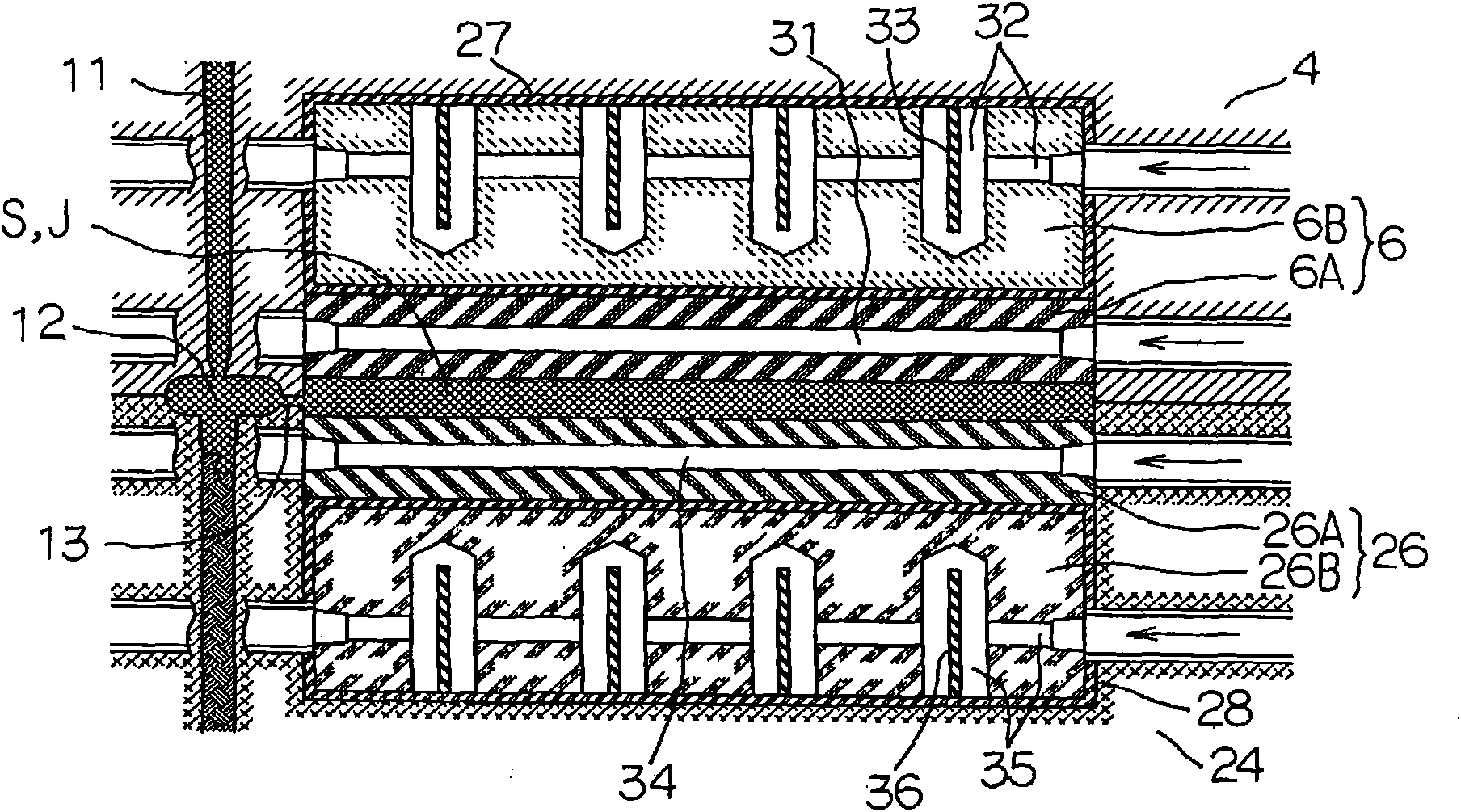

[0054] Below, based on Figure 1 to Figure 5 Embodiments of the present invention will be described. First, based on figure 1 The overall configuration of the injection mold according to the first embodiment of the present invention will be described. 1 is a fixed-side assembly mounted on a fixed platen (not shown) by bolts, and the fixed-side assembly 1 includes: a first fixed-side base plate (base plate) 2 , The fixed-side second base plate 3 fixed to the fixed-side first base plate 2, the fixed-side third base plate 4 fixed to the fixed-side second base plate 3 by screws, and the concave portion arranged on the fixed-side third base plate 4 The fixed mold part 6 inside and fixed to the third bottom plate 4 on the fixed side by screws is arranged on the first bottom plate 2 on the fixed side at a position that is biased to the fixed plate and locates the first bottom plate 2 on the fixed side. A locating ring 7 of the fixed disk, a sprue bush 8 arranged adjacent to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com