[0017] With the wide application of wire rods in major projects, users have put forward higher requirements for the strength and stability of products. Studies have shown that

chemical composition and ambient temperature are the main factors affecting strength stability, but the existing

process control methods cannot effectively resolve these conflicts

[0018] The

chemical composition and ambient temperature are constantly changing, but the parameters such as roller table speed and fan

air volume in the current cooling process of hard line products are basically unchanged. Even if the parameters are adjusted, there is a phenomenon that there is a

lag or cannot be correctly matched with the composition and ambient temperature changes

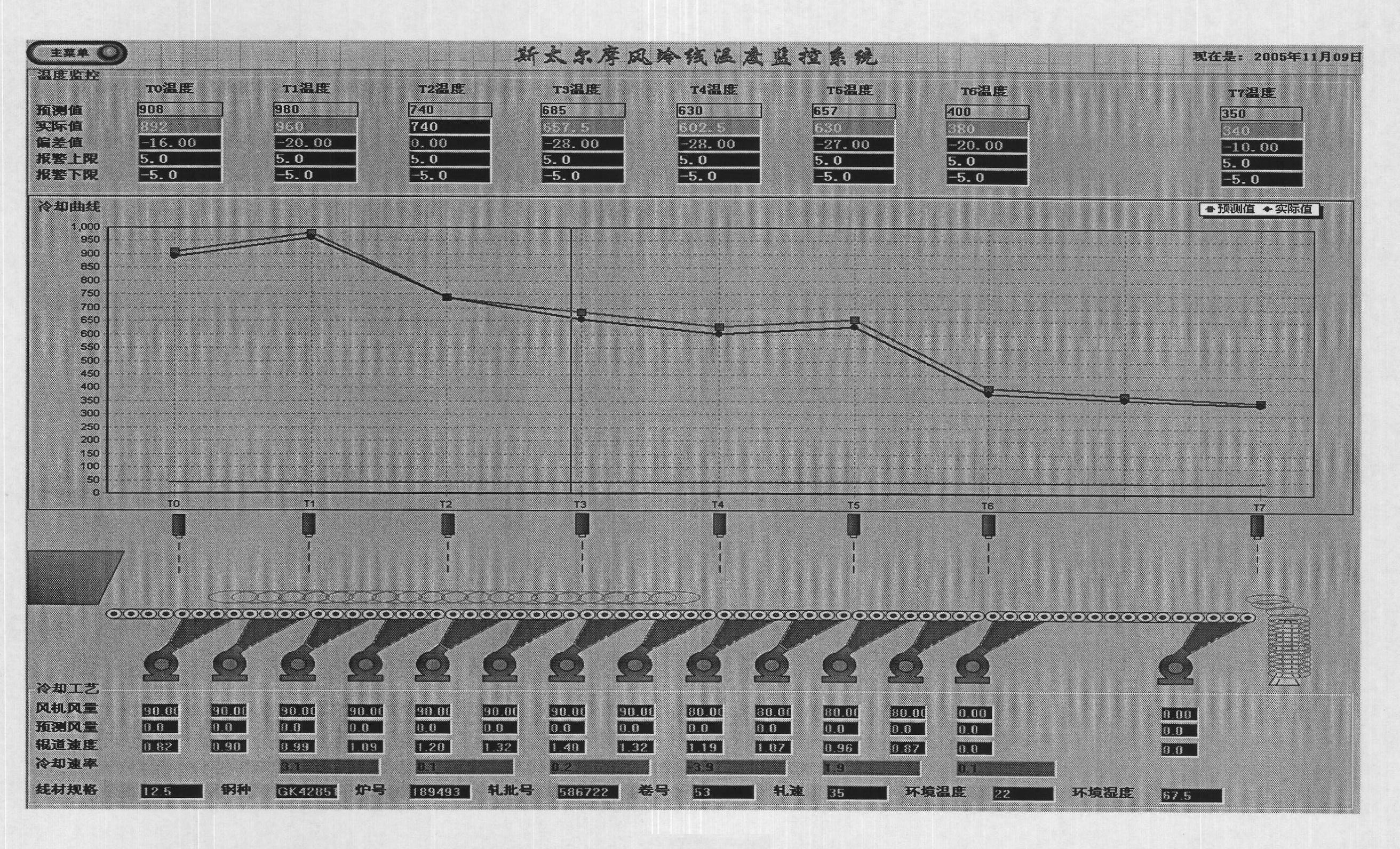

This is mainly because the ultimate goal of adjusting the air volume of the fan, the speed of the roller table and the opening and closing of the heat preservation cover is to control the

cooling speed of the wire rod on the Stelmore line, but since the Stelmore line has only

two temperature points, and the

temperature measurement is Inaccurate and has

no reference value, so it is difficult to quickly and accurately judge the actual effect of adjusting the air volume of the fan, the speed of the roller table, and the opening and closing of the heat preservation cover. We can only wait for the final mechanical test results of the wire rod

However, the test results

lag behind greatly, and some even

lag by 1-2 days. When the test results come out, the rolling batch has already been produced, and it cannot form a closed-loop dynamic adjustment. This series of contradictions has led to the inability of the existing

process control methods. To realize the dynamic closed-loop adjustment, it is impossible to avoid the influence of chemical composition and ambient temperature on the strength stability

[0019] Although the current cooling control of the Steyrmore line is realized through the air volume of the fan and the speed of the roller table, the selection of this process parameter is not reasonable, and it is an indirect control method.

[0020] 2. It is difficult to optimize the organizational performance of existing products

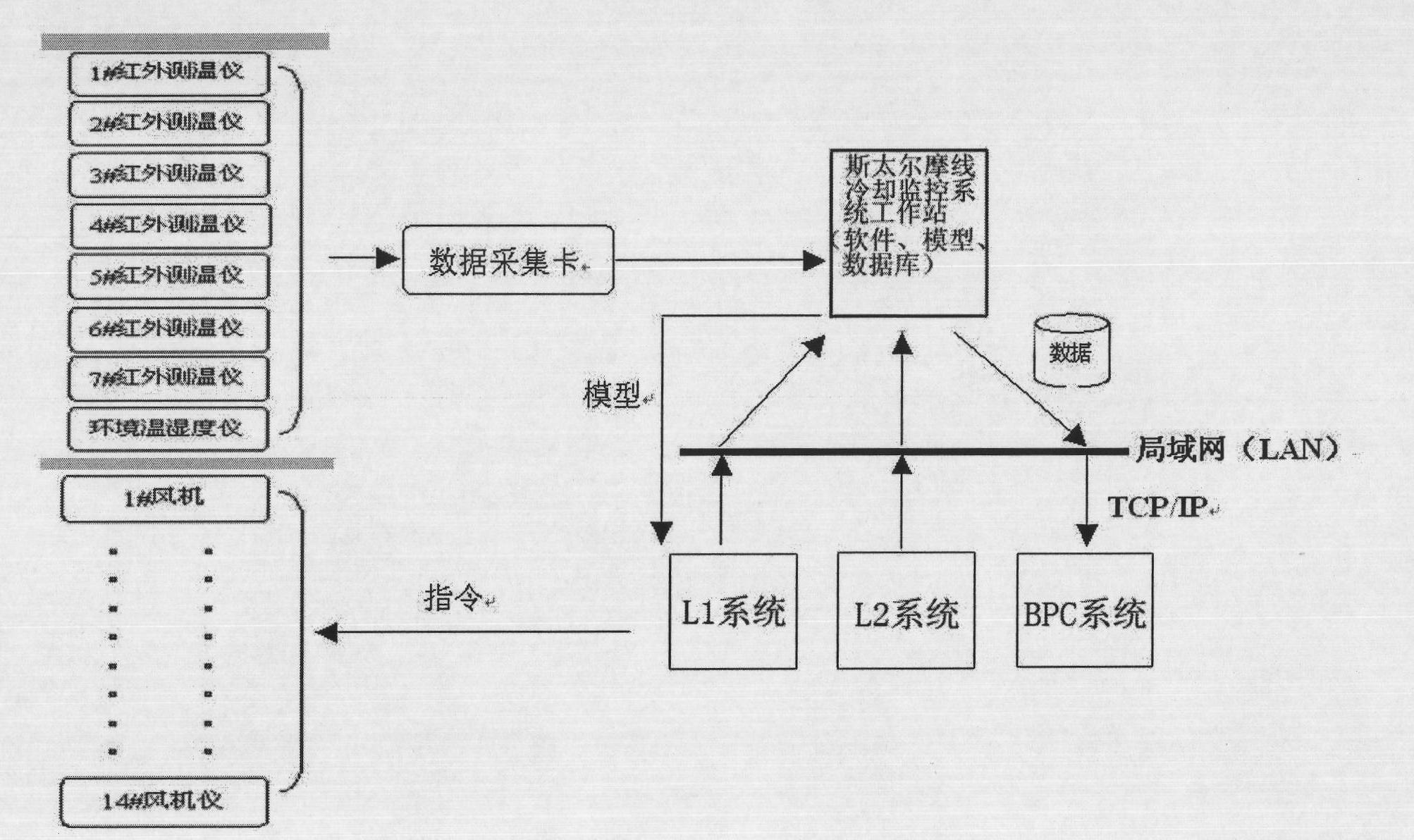

[0022] 1) Incomplete data collection makes it difficult to carry out systematic and comprehensive analysis and research. The accuracy of the Stelmore line temperature stored in the L2

system cannot be guaranteed, the stored fields are not comprehensive, and the chemical composition, Stelmore temperature and Relevant data such as tensile strength are organically connected, resulting in the inability to conduct systematic and comprehensive analysis

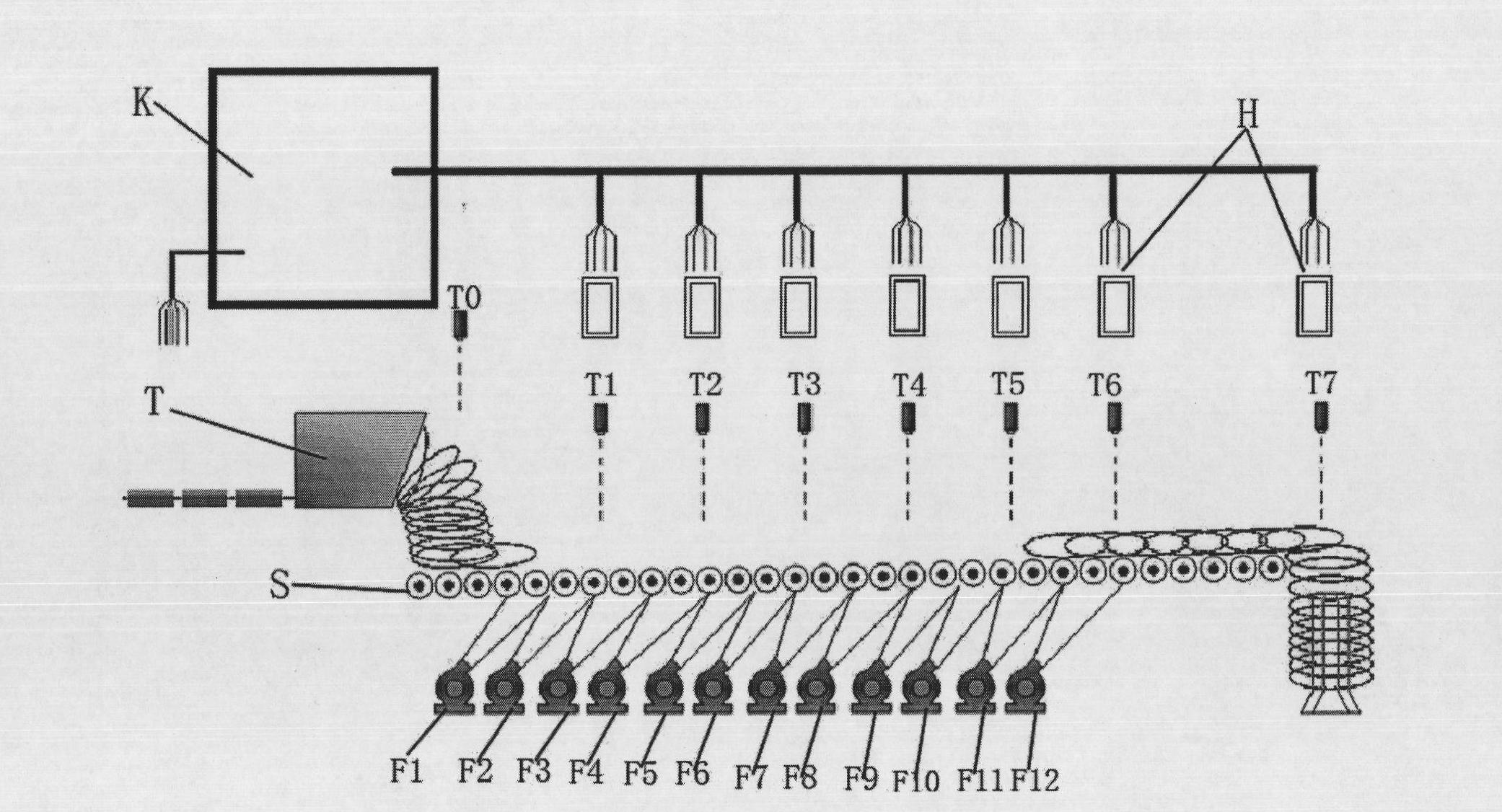

[0023] 2) There are defects in the hardware configuration. There were only two thermometers in the Stelmore line. The number of thermometers was seriously insufficient to reflect the

cooling effect of each section, and the

temperature measurement value was randomly selected at regular intervals. Often the wire rod The temperature is confused with the roller table temperature and cannot reflect the true temperature of the wire rod

Historical events also show that the existing

thermometer configuration cannot detect abnormal conditions such as fan failures, resulting in the appearance of products with unqualified batch performance. Therefore, it is necessary to improve the hardware configuration of the Stelmore line temperature detection

[0024] 3) There is a lack of a control model and precise control cannot be achieved. In order to effectively improve the stability of wire strength, it is necessary to establish a control model for strength stability and find the quantitative relationship between strength and its main influencing factors (chemical composition and ambient temperature). Due to the lack of specialized research and incomplete data, this model cannot be established; 4) There is no special

software to support the research and improvement of the Stelmore process. In addition to the lack of hardware, there is also a lack of special

software for information display,

data acquisition, and model analysis. , cooling adjustment and other work, it is difficult to improve the cooling of the Steyrmore wire and optimize the structure and performance of the product

However, as stated in this patent, the purpose is to improve the cooling strength of the Stelmore wire while solving the problems of

lap joint structure and uneven performance

[0026] At present, the Stelmore cooling line is widely used in high-speed wire rod production lines, but the outstanding disadvantages of this process are: on the air-cooled line, the coil

density distribution is uneven, the wire density is the largest at the

lap joint, and the wire density is the smallest at the center of the coil , so the

cooling rate at the overlapping point of the coil is not only lower than that at other positions, but also the initial position of the

phase change and the time of the

phase change have different degrees of lag

[0027] Although the degree of unevenness can be changed by adjusting the Jialing device or changing the speed of the roller table, the difference in the performance of the same coil of the wire is still large

Login to View More

Login to View More  Login to View More

Login to View More