Three-wash bottle washing machine for wild-mouth bottles

A wide-mouth bottle and three-flushing technology, which is applied in the direction of dryers, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of inability to clamp wide-mouth bottles, poor cleaning effect, single function, etc., and achieve processing and assembly Time-saving and labor-saving, convenient installation, and guaranteed flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

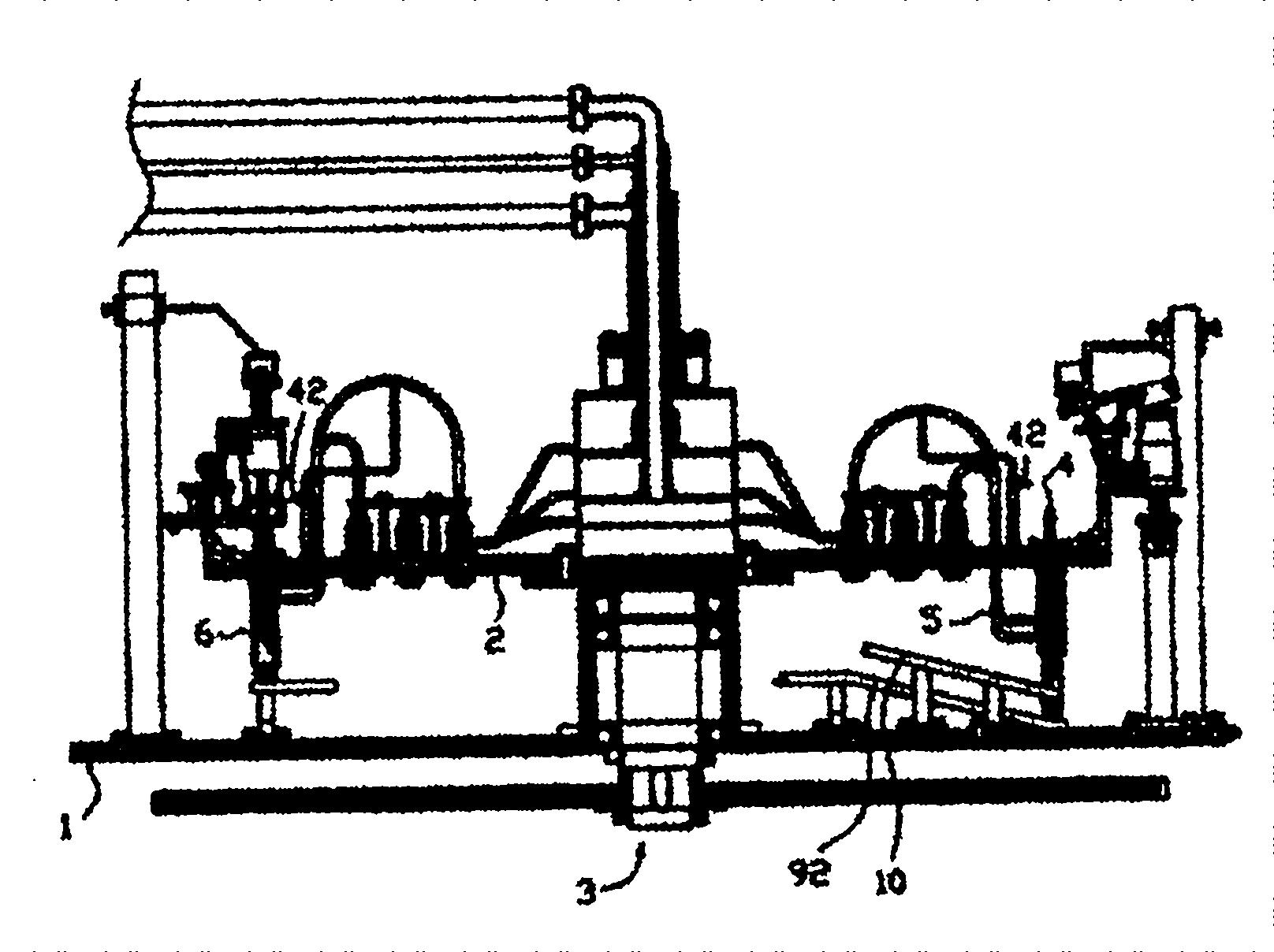

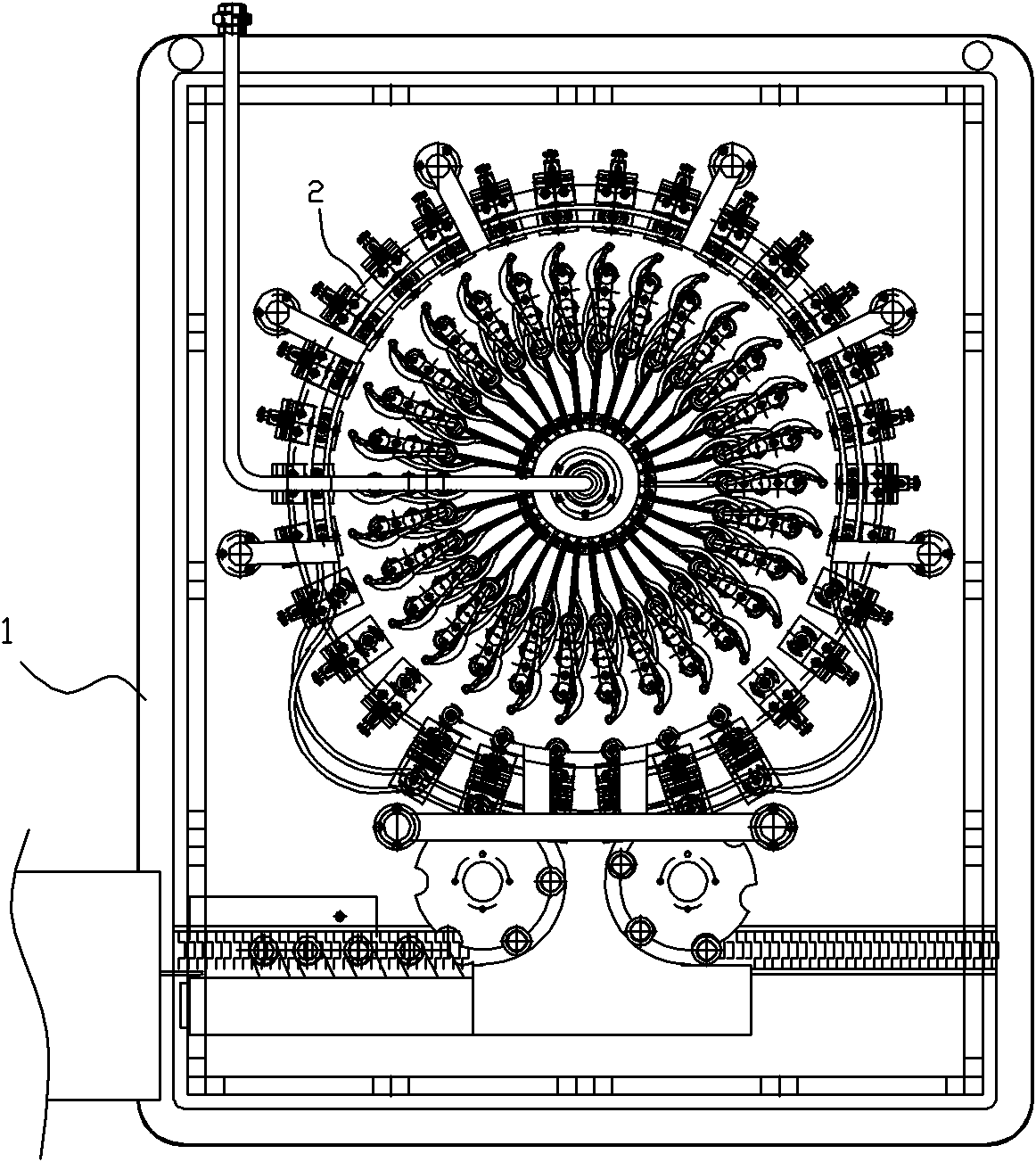

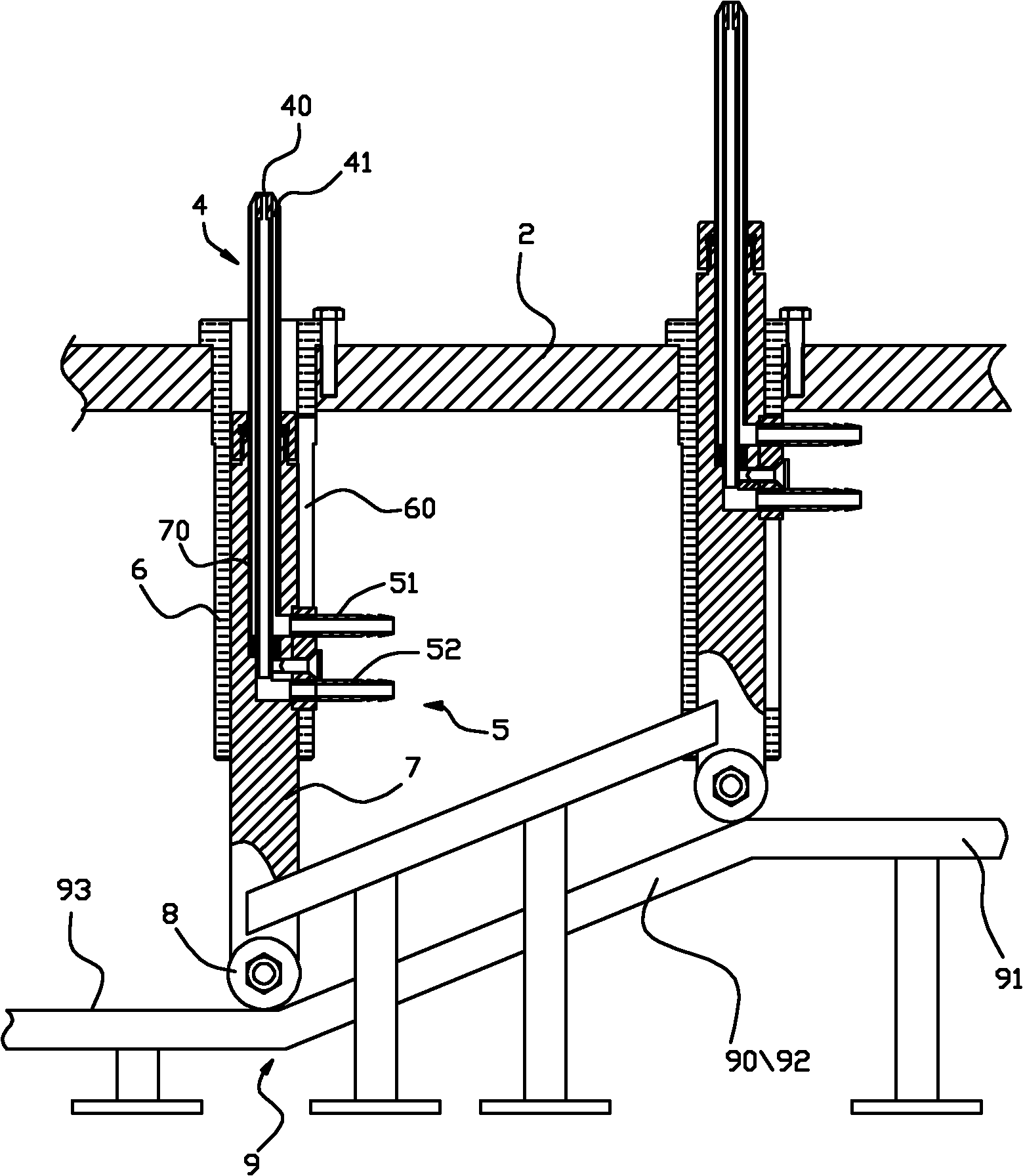

[0026] see figure 1 with Figure 9 , shows a preferred mode of a three-flush bottle rinser for wide-mouth bottles of the present invention, which includes a frame platform 1, a turntable 2 and several valve groups 10 that are arranged on the frame platform and driven by a main shaft 3 to rotate. Between the turntable 2 and the frame platform 1, a plurality of spray pipes 4 that can move up and down are evenly arranged along the circumferential direction, and one end of each of the spray pipes can extend into the mouth of a wide-mouth bottle that is arranged upside down above it. The other end of the spray pipe 4 communicates with the water inlet and / or air duct 5, and several positioning guide sleeves 6 are correspondingly arranged between the turntable 2 and the frame platform 1 along the circumferential direction, and the upper end of each positioning guide sleeve 6 Fixed on the turntable, each positioning sleeve is provided with a guide column 7 that can slide up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com