Air separator for sucking granular materials by jet flow

A granular material and sorter technology, applied in the direction of separating solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problem of limited vacuum, high sealing requirements of feed hoppers, and limited use and other issues to achieve the effect of reducing the power system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

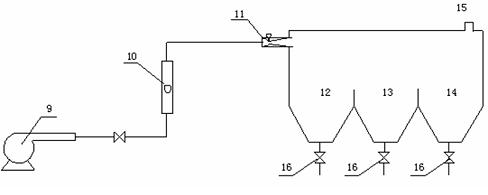

[0027] The specific embodiment of the present invention is that the broken waste printed circuit boards are sorted by shaking table, such as image 3 Shown is the flow chart of solid waste treatment wind separation process, in which 9 is the SSR-50 three-lobe Roots blower; 10 is the flow meter; 11 is the jet suction particle material wind separator; 12 is the heavy material tank; 13 is Medium material tank; 14 is a light material tank; 15 is an air outlet; 16 is a discharge port.

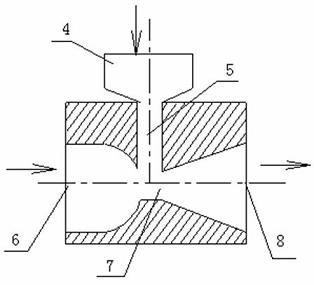

[0028] The crushed waste printed circuit boards are sorted by a shaking table, and then the intermediate product sorted by the shaking table is sent to a jet suction particle material wind separator for separation. The diameter of the nozzle of the wind separator is 2.1cm, and the pipe diameter It is 4cm, and the tube length is 5.34cm.

[0029] According to the sieving analysis, the particle size of this batch of intermediate products is in the range of 1-0.5mm, mainly composed of plastic, Al, SiO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com