Refining concentration automatic control system

An automatic control system and refining technology, applied in food preparation, application, food science and other directions, can solve the problems of production impact, inability to continuously produce soybean milk products according to needs, etc., to avoid waste, improve labor productivity, and ensure control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

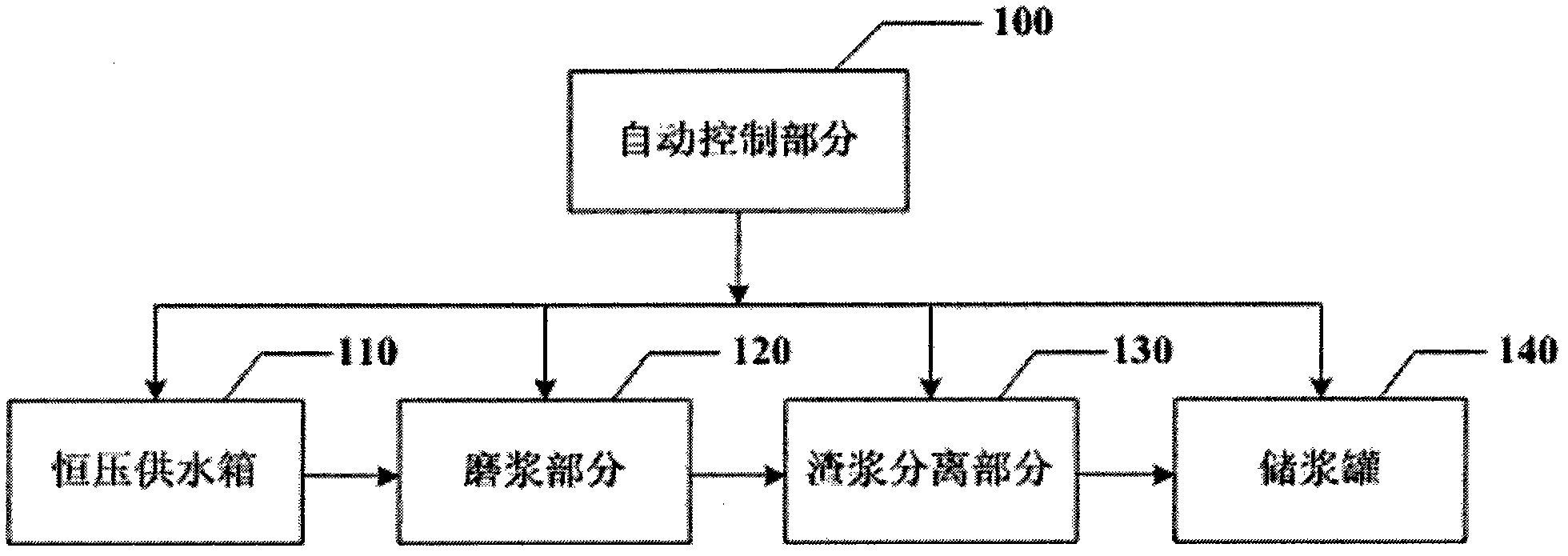

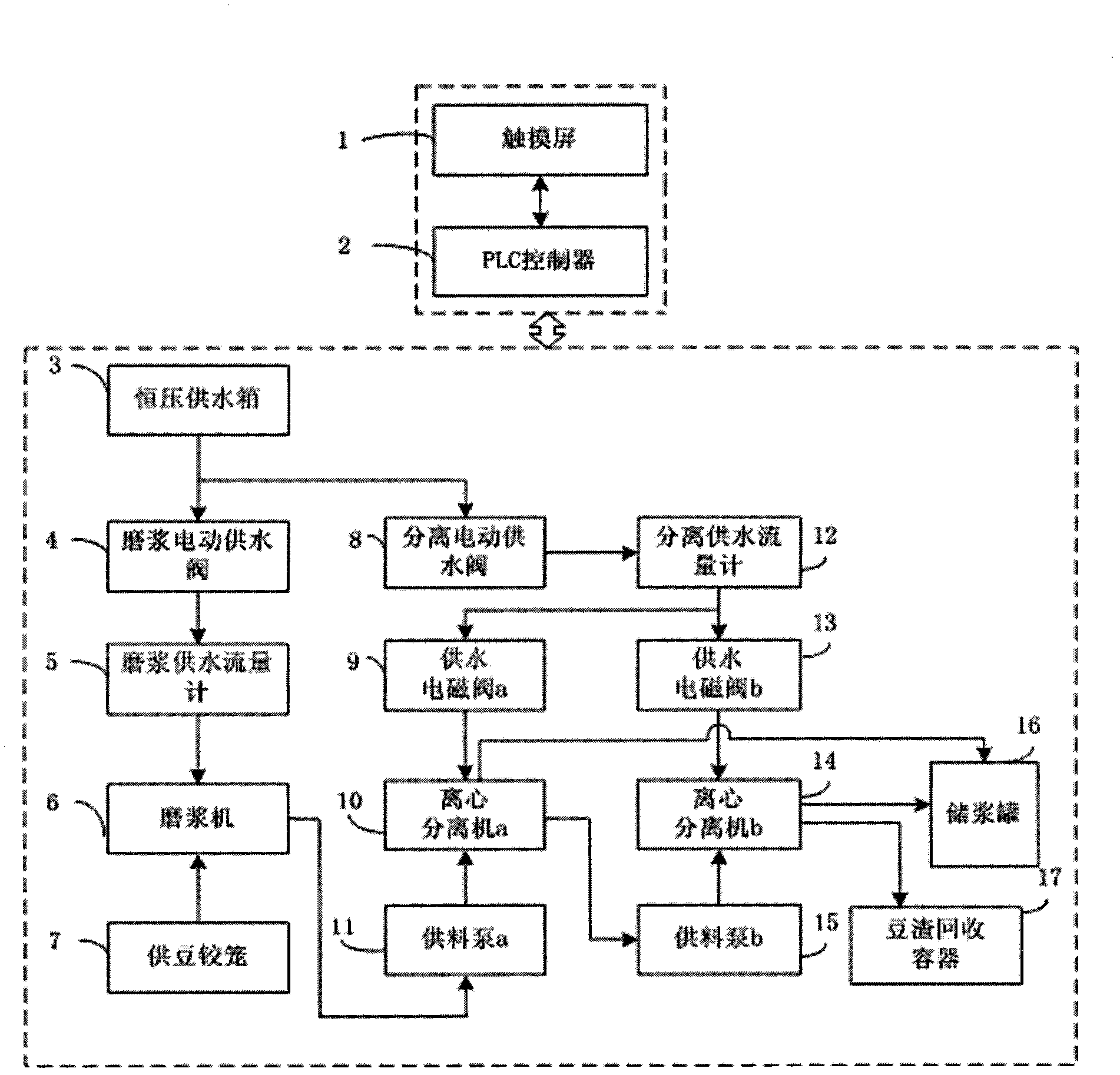

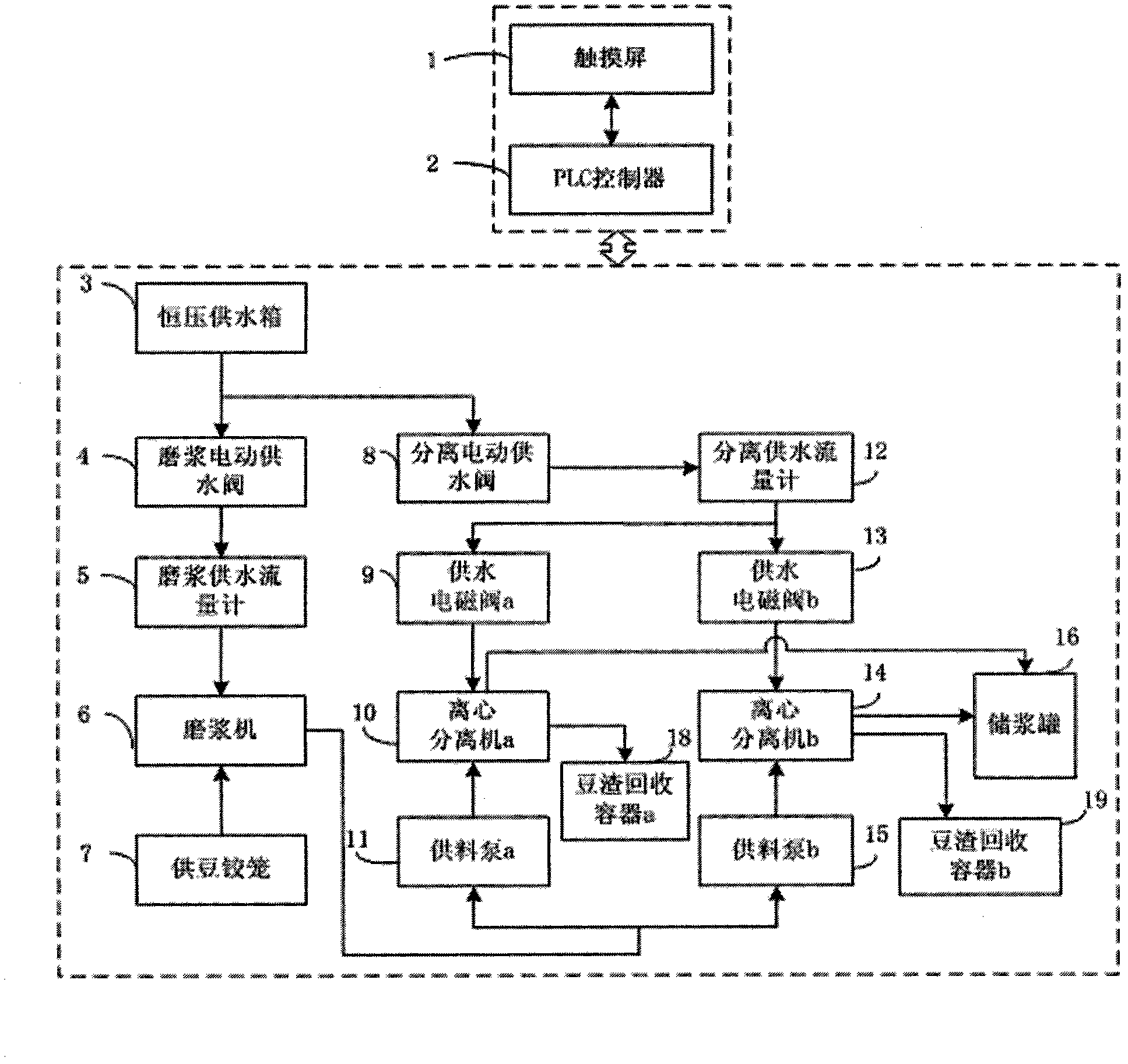

[0035] like figure 1 and figure 2 As shown, the present invention provides an automatic control system for refining concentration, which is composed of a constant pressure water supply tank 110, a refining part 120, a slurry separation part 130 and a slurry storage tank 104 respectively connected to the automatic control part 100. The water supply tank 110 is respectively connected with the slurry refining part 120 and the slurry separation part 130 , and the slurry refining part 120 is connected with the slurry separation part 130 and the slurry storage tank 140 in sequence. Among them, the automatic control part is composed of a touch screen 1 and a PLC controller 2, which are used to set the process parameters, control parameters and maintenance information of the system, and control the refining and slurry separation system to achieve precise control of the refining speed and concentration; The slurry part is composed of a refining quantitative water supply device and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com