Universal joint for submarine optical cable connector box

A submarine optical cable and splice box technology, applied in the direction of pivot connection, fiber mechanical structure, etc., to achieve the effect of excellent bending performance, convenient construction and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

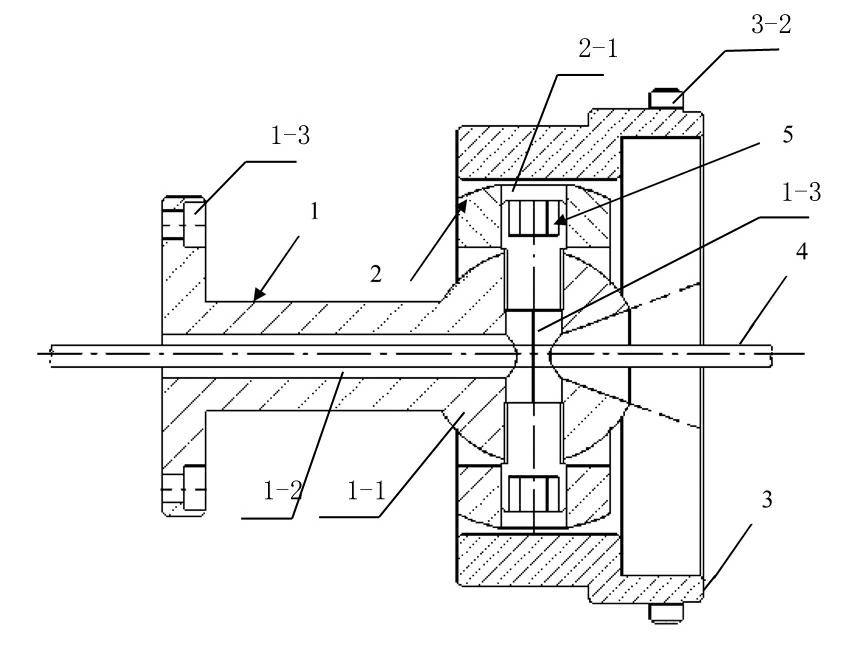

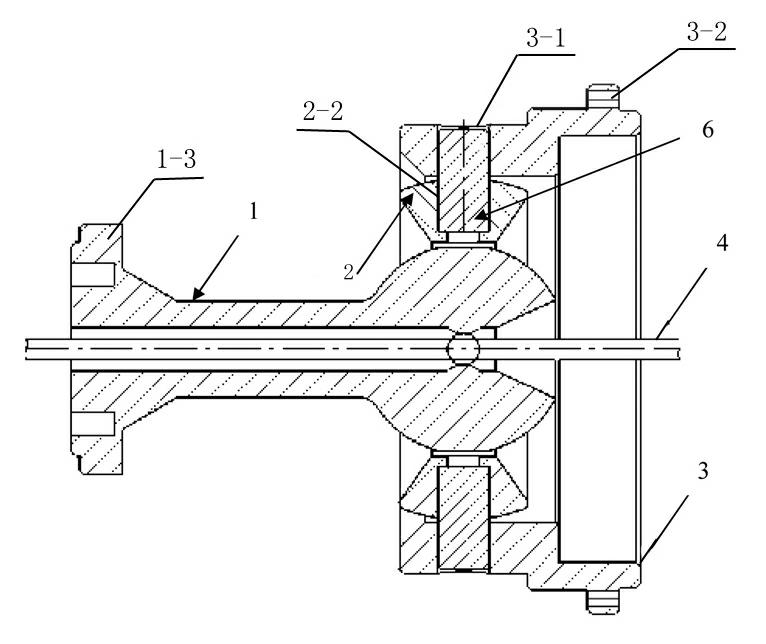

[0015] Refer to attached Figure 1~3 , The universal joint for the submarine optical cable joint box is composed of three main components: joint 1, bushing 2, connecting sleeve 3, and three main components. The joint 1 is provided with a ball head (ball) 1-1, and the bushing 2 is set on the ball head (ball) 1-1 of the joint 1 and connected with a pin 5; on, connected with pin 6. see figure 1 and figure 2 . The bending limiter 7 is connected with the other end of the connecting sleeve 3, and the joint 1 is connected with the rigid part of the joint box. In this way, the bending limiter 7 and the splice box body 8 are connected with a universal joint through the submarine optical cable splice box, see image 3 .

[0016] The central axis of the joint 1 has a through hole 1-2 for wearing the optical cable 4, the ball head has a ball head through hole 1-3; the side of the bush 2 has a symmetrical counterbore 2-1. The joint 1 and the bushing 2 are connected by two pins 1-5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com