Method for examining data file of curve surface reverse product

A technology of data files and curved surfaces, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficult inspection efficiency, time-consuming, high CAD technical requirements, etc., and achieve the effect of broad application prospects and high measurement repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

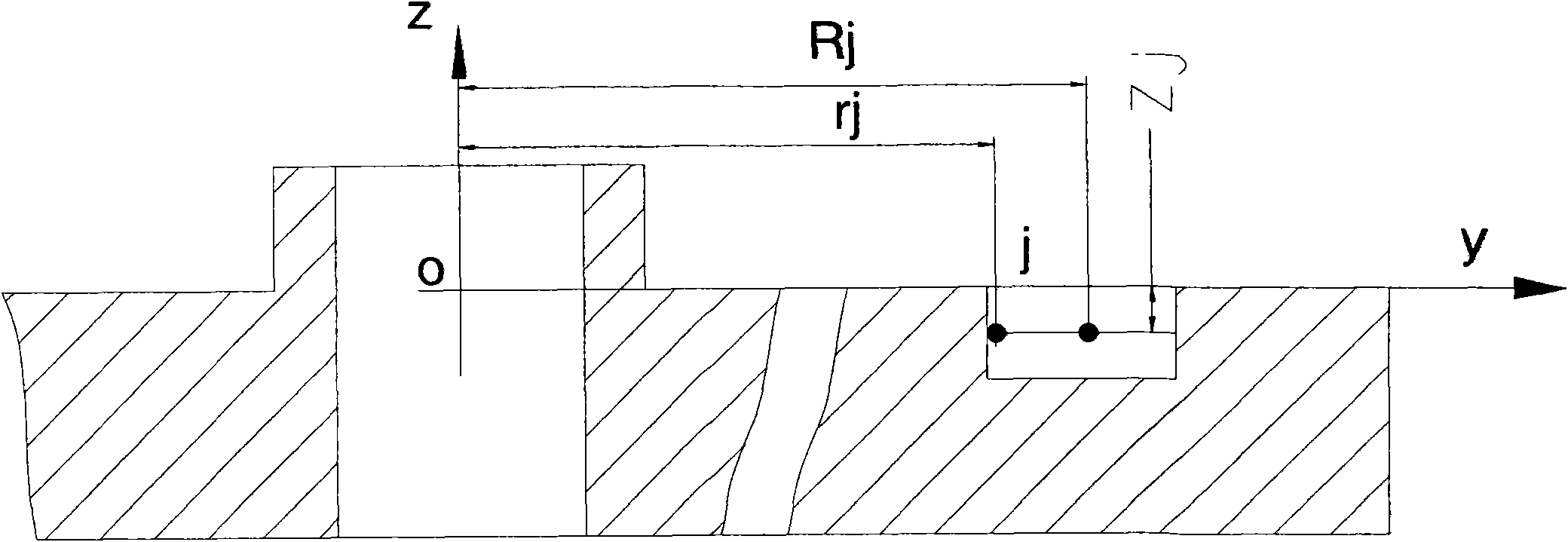

[0046] The data file inspection method of the curve surface reverse product of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] First, for the flat disc cam series:

[0048] Such as figure 1 with figure 2 Shown is a partial diagram of the cam curve. The polar coordinate system is used in the measuring coordinate system of the plane disc cam surface, and the origin is set at the center of the base circle of the plane disc cam. S1 and S2 represent the actual contour curve of the cam, M1 and m2 represent the curve trajectory of the actual contour line measured by the stylus center, M2 and m1 represent the starting point trajectory curve of the stylus center measurement and positioning, where M1 and m2 are curves S1 and S2 respectively The equidistant curves have a difference of one stylus radius between them. The S curves are the centerlines of S1 and S2, and also the centerlines of curves M1 and m2. Actually, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com