Method for reducing excess sludge of aerobic unit of sewage treatment system by activated sludge process

A technology of sewage treatment system and activated sludge method, which is applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc., can solve the problem of reduced sludge activity and achieve the effect of strong performance

- Summary

- Abstract

- Description

- Claims

- Application Information

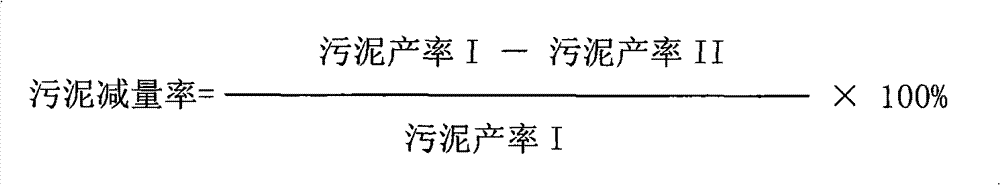

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8、 comparative example 1~2

[0029] The treated sewage is oil refinery sewage, which is treated by oil separation and coagulation flotation. The quality of the influent water is:

[0030] COD575mg / l

[0031] pH 8.2

[0032] Sequenced batch activated sludge process (SBR process) is used for treatment, and the reactor volume is 8m3. The process includes: water inflow-aerobic reaction-sedimentation-decanting water-anaerobic (reciprocating), the operation of aerobic reaction process The process conditions are:

[0033] Sludge load 0.4~0.9kgBOD 5 / (kgMLVSS·d)

[0034] Reaction temperature 20~30℃

[0035] Dissolved oxygen 2~4mg / l

[0036] The amount of uncoupling agent added in sewage is shown in Table 2

[0037] (calculated in TCS)

[0038] The composition of the uncoupling agent that embodiment 1~8, comparative example 1~2 adopts comprises TCS, all the other components and proportioning ratio are listed in table 1, and the specific surface area of diatomite used is 30~60m 2 / g, the particle size of ...

Embodiment 9~16

[0040] The treated sewage is ethylene glycol production sewage, and the quality of the influent water is:

[0041]COD 2050mg / l

[0042] pH value 6~9

[0043] The AB activated sludge process is used for treatment, and the process includes in turn: water inflow-high-load aerobic treatment in section A-intermediate sedimentation tank-low-load aerobic treatment in section B-final sedimentation tank-drainage, intermediate sedimentation tank and final sedimentation tank Part of the sludge is returned to the respective aerobic tanks, and the remaining sludge is discharged. Embodiments 9 to 16 carry out sludge reduction treatment for the high-load aerobic unit of section A with high sludge yield (including high-load aerobic treatment and intermediate sedimentation tank of section A), and the operating process conditions are:

[0044] Sludge load 2~4kgBOD 5 / (kgMLVSS·d)

[0045] Reaction temperature 20~30℃

[0046] Dissolved oxygen 0.5~1mg / l

[0047] The amount of uncoupling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com