Ultraprecise drum-shaped roller and processing method thereof

A processing method, ultra-precise technology, applied in the processing of ultra-precision drum-shaped rollers, the field of ultra-precision drum-shaped rollers, can solve the problems of difficult drum-shaped roller processing, short production preparation period, long production preparation period, etc., to eliminate Overcut phenomenon, short production preparation cycle, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings.

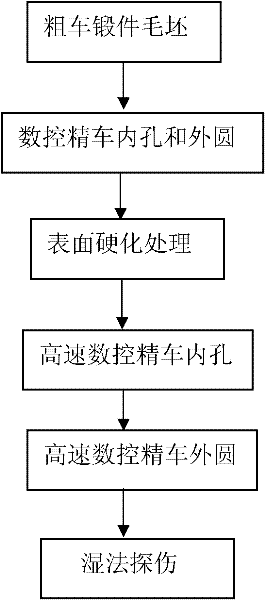

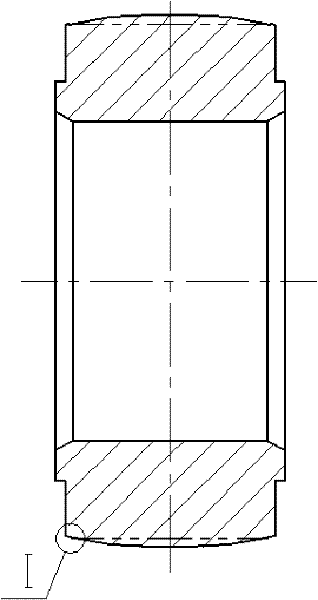

[0025] like figure 1 Shown is the flow chart of the ultra-precision drum-shaped roller processing method of the present invention. A method for processing an ultra-precision drum roller, comprising the following steps:

[0026] 1) Roughly turning the forging blank into shape;

[0027] Specifically include: rough turning the blank with a common lathe, leaving a margin of 2mm.

[0028] 2) The inner hole and outer circle of the finished workpiece;

[0029] The specific content includes: using a general-precision CNC lathe, the inner hole and outer circle of the workpiece are fine-turned, and the surface roughness of the workpiece is required to be ≤ Ra0.8, leaving a margin of 0.2-0.5mm to ensure the coaxiality of the inner hole and the outer circle Within 0.01mm.

[0030] The general-precision CNC lathe here means that the speed of the lathe generally does ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com