High-voltage transformer

A technology for high-voltage transformers and transformer cores, applied in the field of high-voltage transformers, can solve the problems of increasing the weight of dry-type transformers, and achieve the effect of weight saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

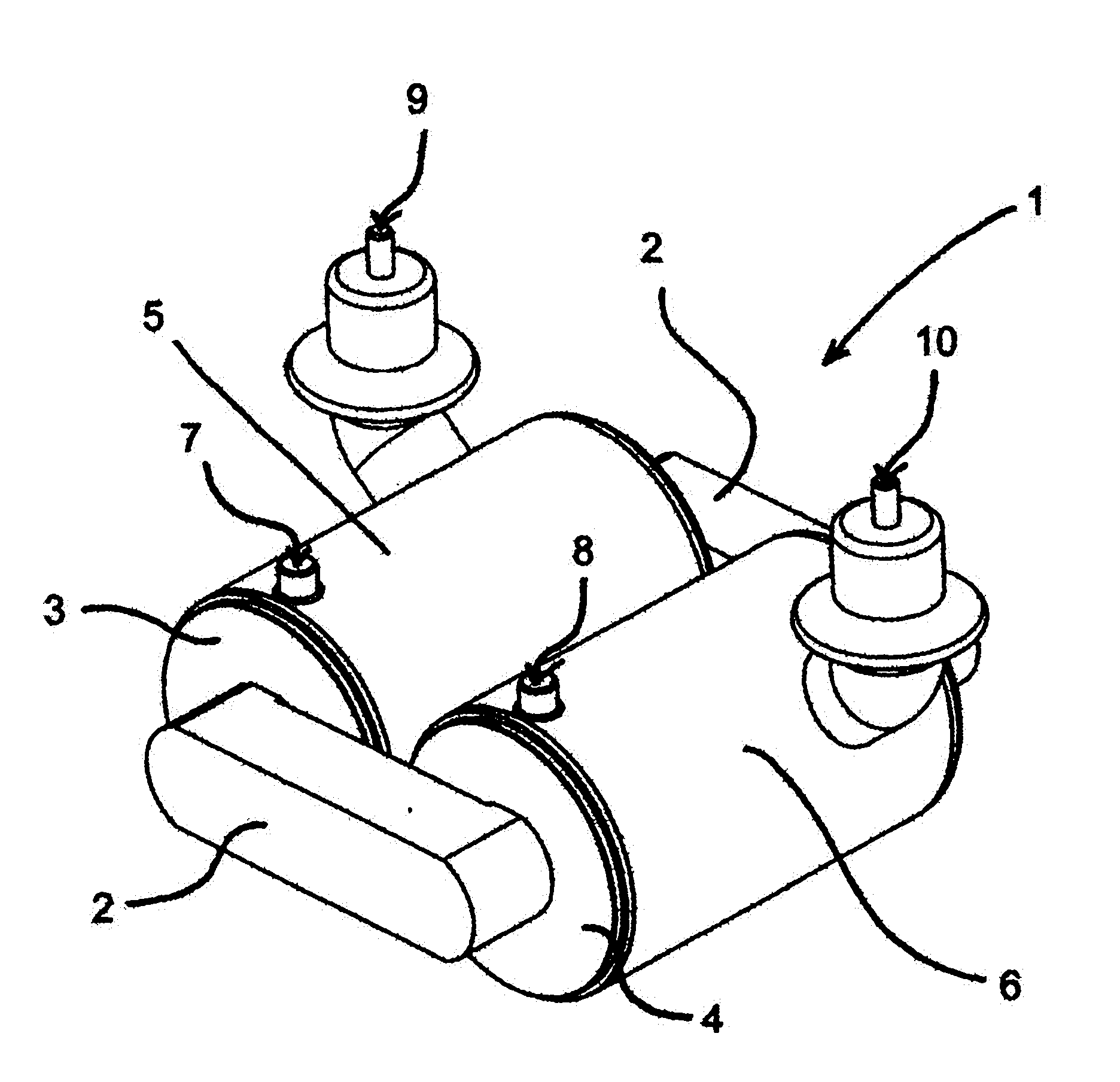

[0042] exist figure 1 The high-voltage transformer 1 shown in FIG. 2 comprises a ferromagnetic transformer core 2 around which two primary windings 3 , 4 (designed as disk windings and separately insulated) are currently wound on different arms.

[0043] in addition, figure 1 Shown are two insulating housings 5, 6 each enclosing one arm of the transformer core 2, wherein a low-voltage-side connection 7, 8 and Connectors 9, 10 on the high pressure side. All connections 7 , 8 , 9 , 10 are designed in such a way that they make contact with the relevant end of the secondary winding or that corresponding contacting takes place through them.

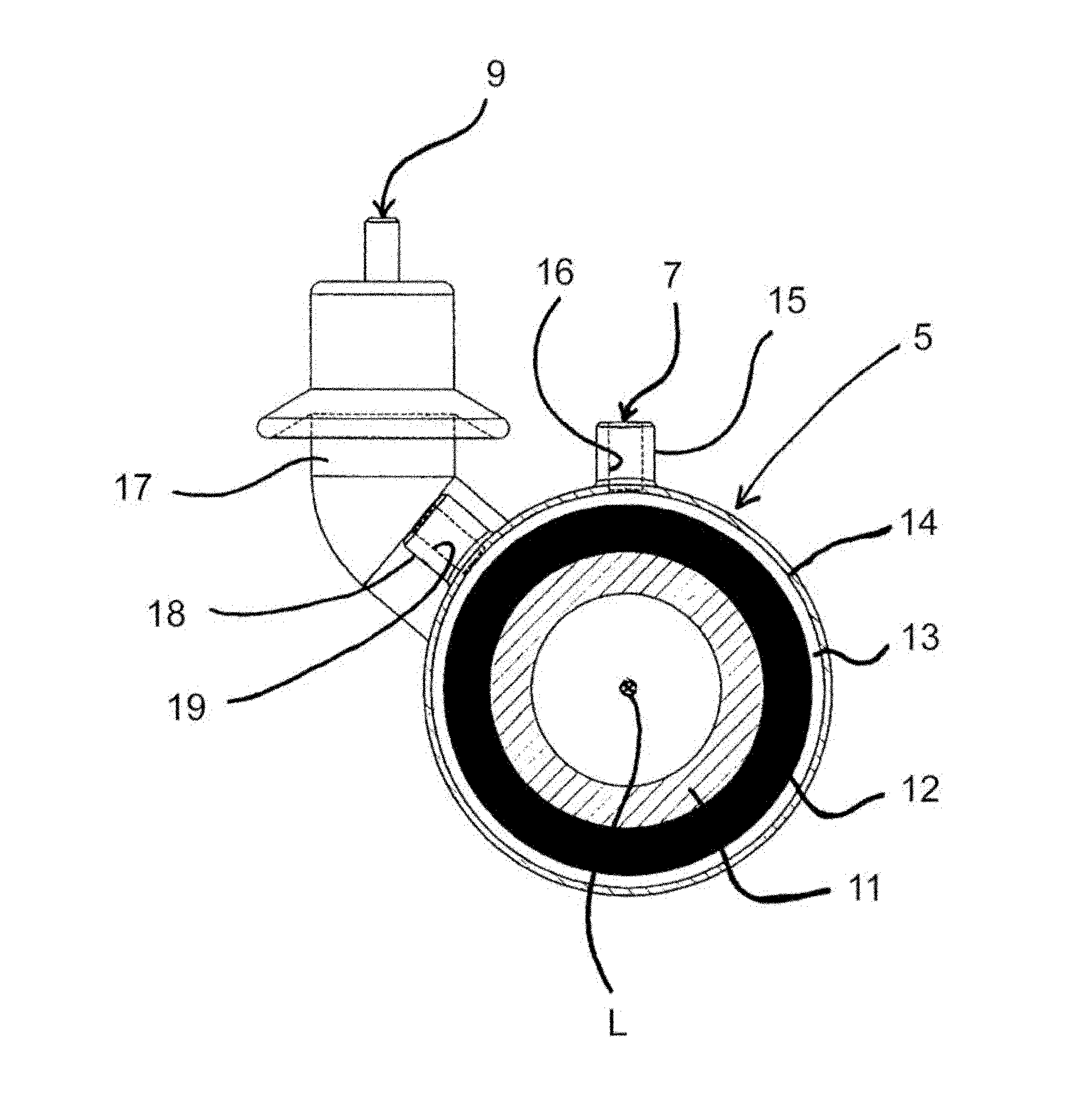

[0044] figure 2 The shown sectional view is perpendicular to the longitudinal axis L of the insulating housing 5 and, for reasons of clarity, both through the connection 7 on the low-voltage side and through the connection 9 on the high-voltage side, so that the exact structure of the insulating housing 5 can be drawn , which has the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com