Hub unit bearing

A wheel hub unit and bearing technology, which is applied in the direction of wheel bearings, bearings, hubs, etc., can solve the problems of low degree of freedom, increased processing cost, and inability to fully ensure the fitting strength, so as to maintain the strength and ensure the fitting strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The first example of embodiment

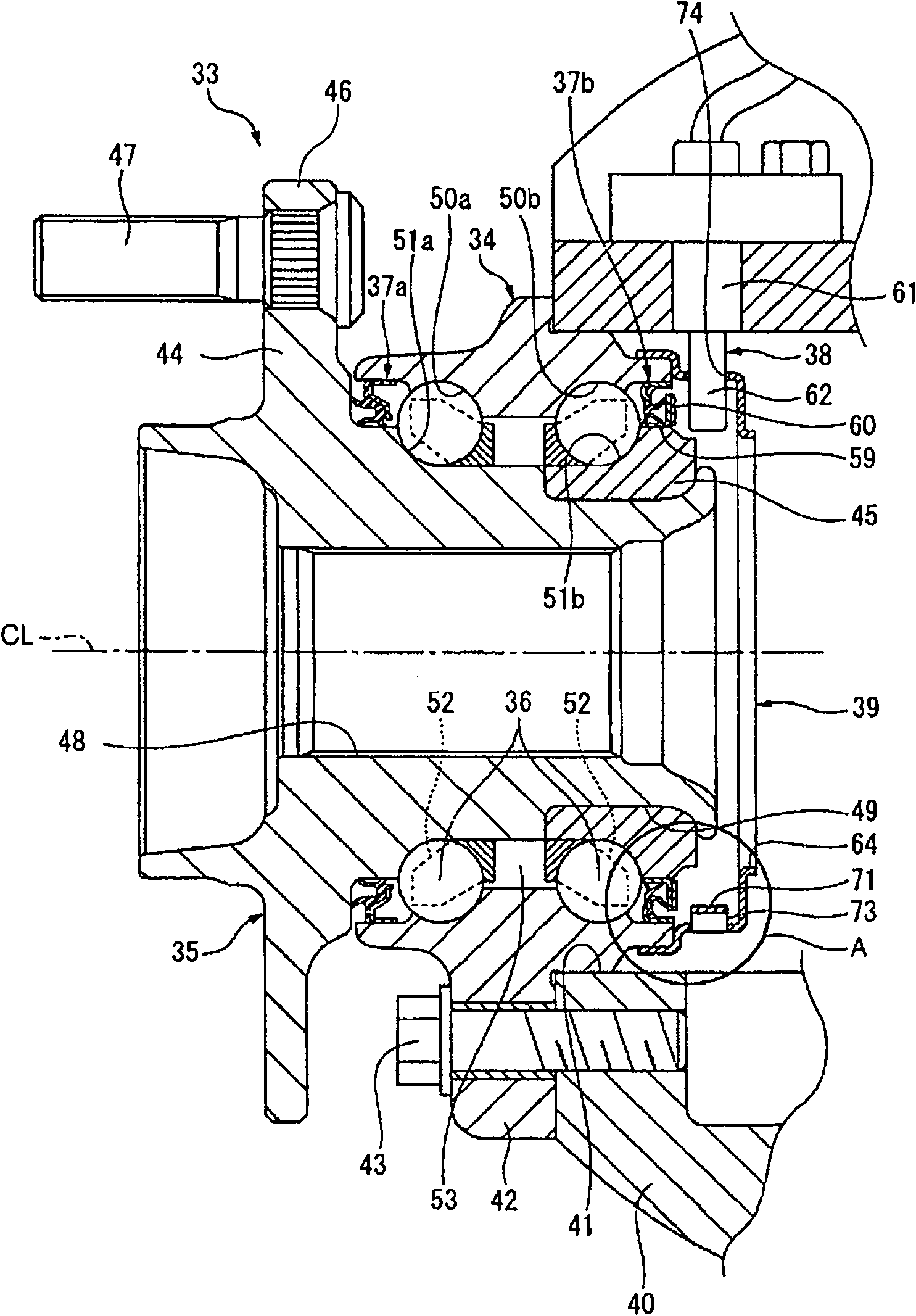

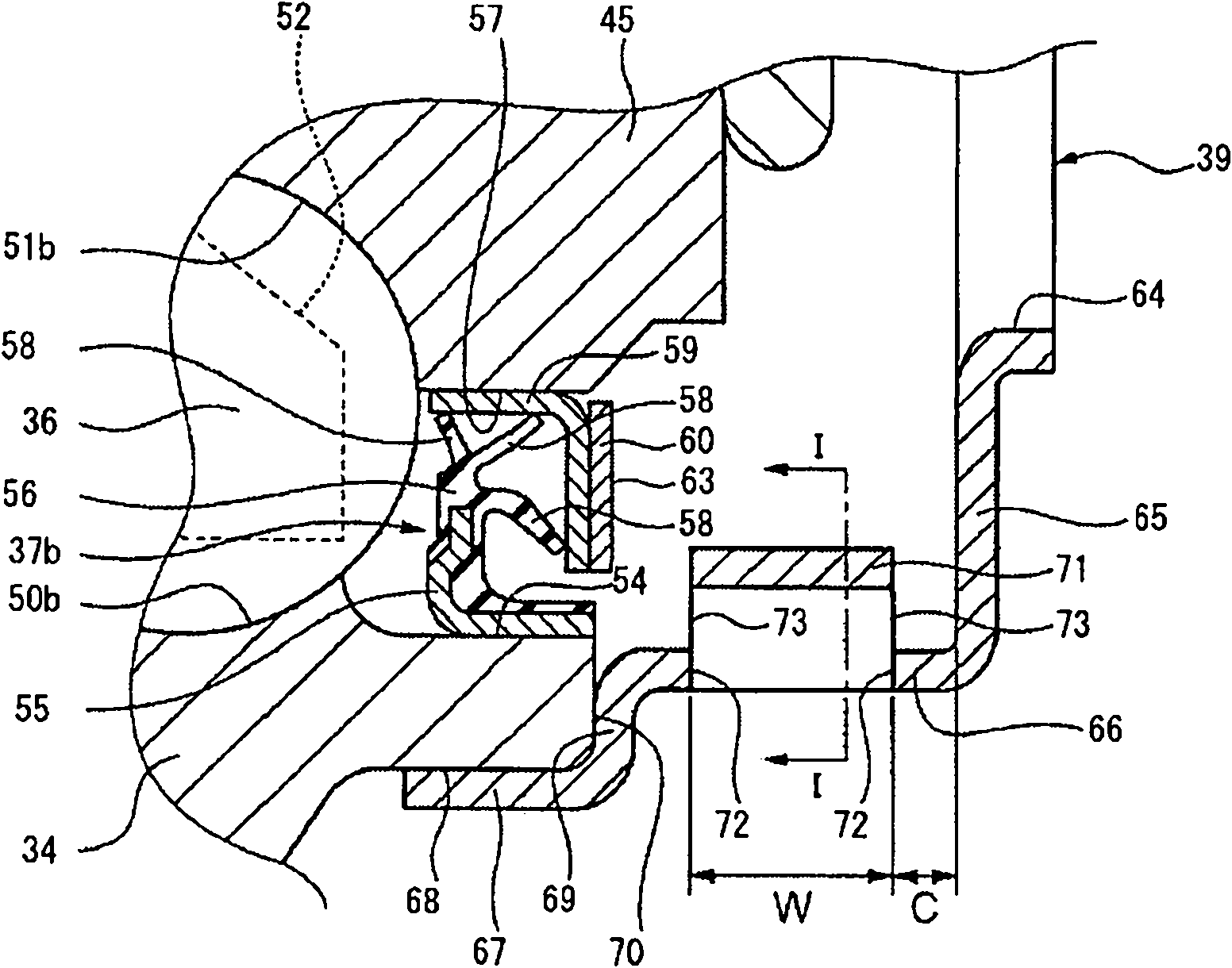

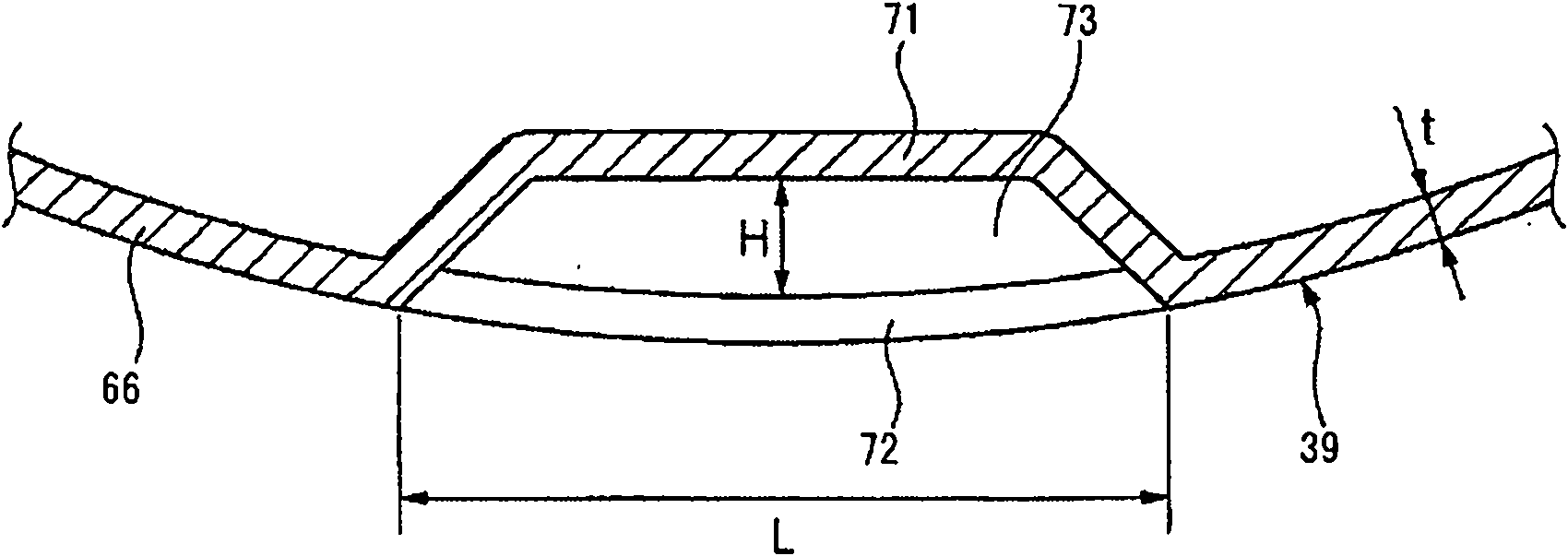

[0078] Figure 1 to Figure 10 A first example of an embodiment of the hub unit bearing of the present invention is shown. The hub unit bearing 33 of this example is the hub unit bearing that drive wheel is used, as figure 1 As shown, the hub unit bearing 33 includes: an outer wheel member 34; a hub 35 as an inner wheel member; a plurality of balls 36 as rolling elements; sealing devices 37a, 37b; a rotation speed detection device 38;

[0079] The above-mentioned outer wheel member 34 is a stationary wheel, which is embedded in a holding hole 41 of a steering knuckle 40 fixed on the vehicle body (not shown), and a stationary side flange 42 provided on the outer peripheral surface of the outer wheel member 34 is fastened by bolts 43 . It is fixed on the steering knuckle 40 , so that the outer wheel member 34 is combined and fixed on the steering knuckle 40 .

[0080] In addition, the hub 35 is a rotary wheel and is formed by combining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com