Magnetic induction heating method and special devices

A heating method and special device technology, applied in the field of magnetic eddy current induction, can solve the problems of high power consumption and small application range, and achieve the effects of low power consumption, wide application range and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

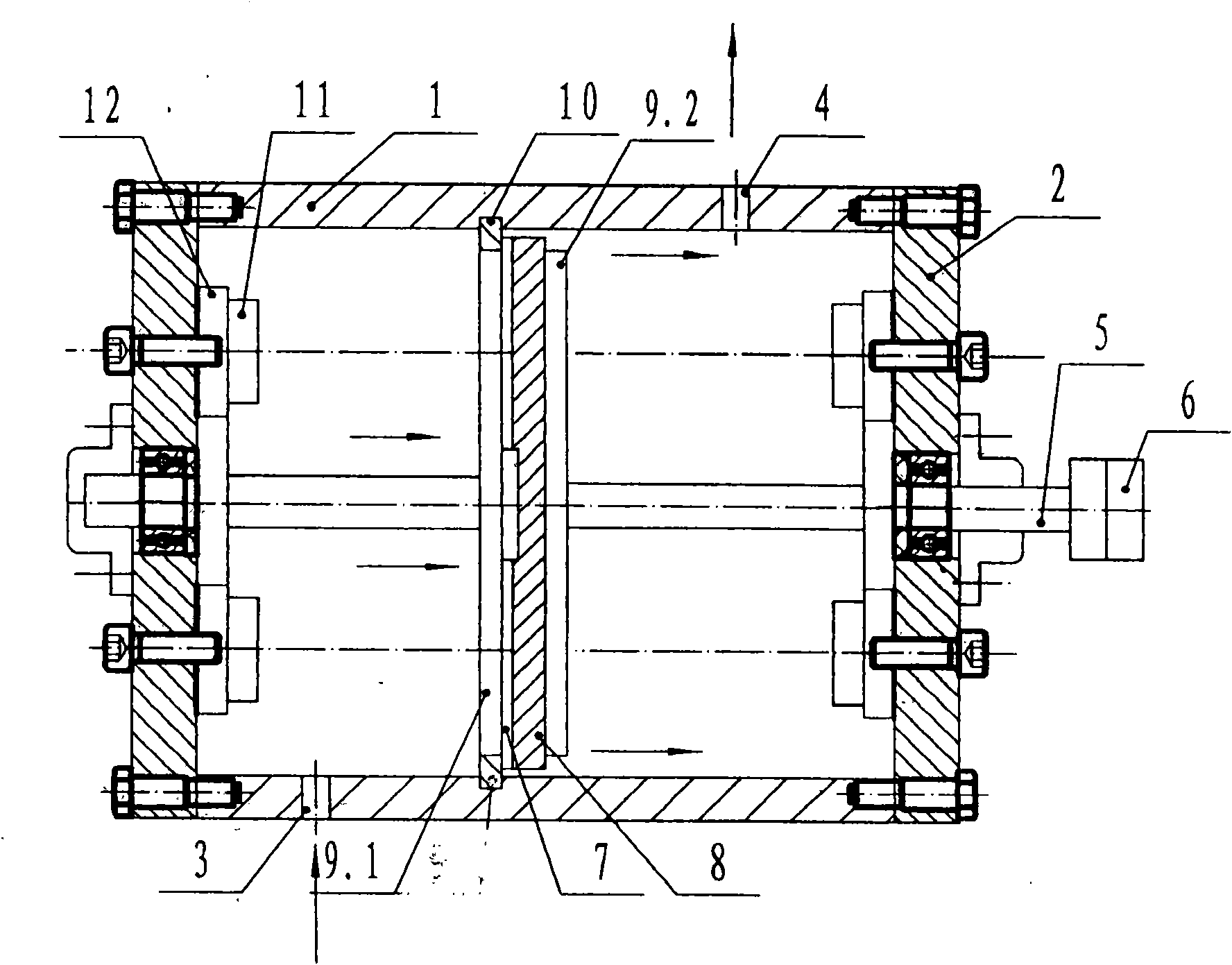

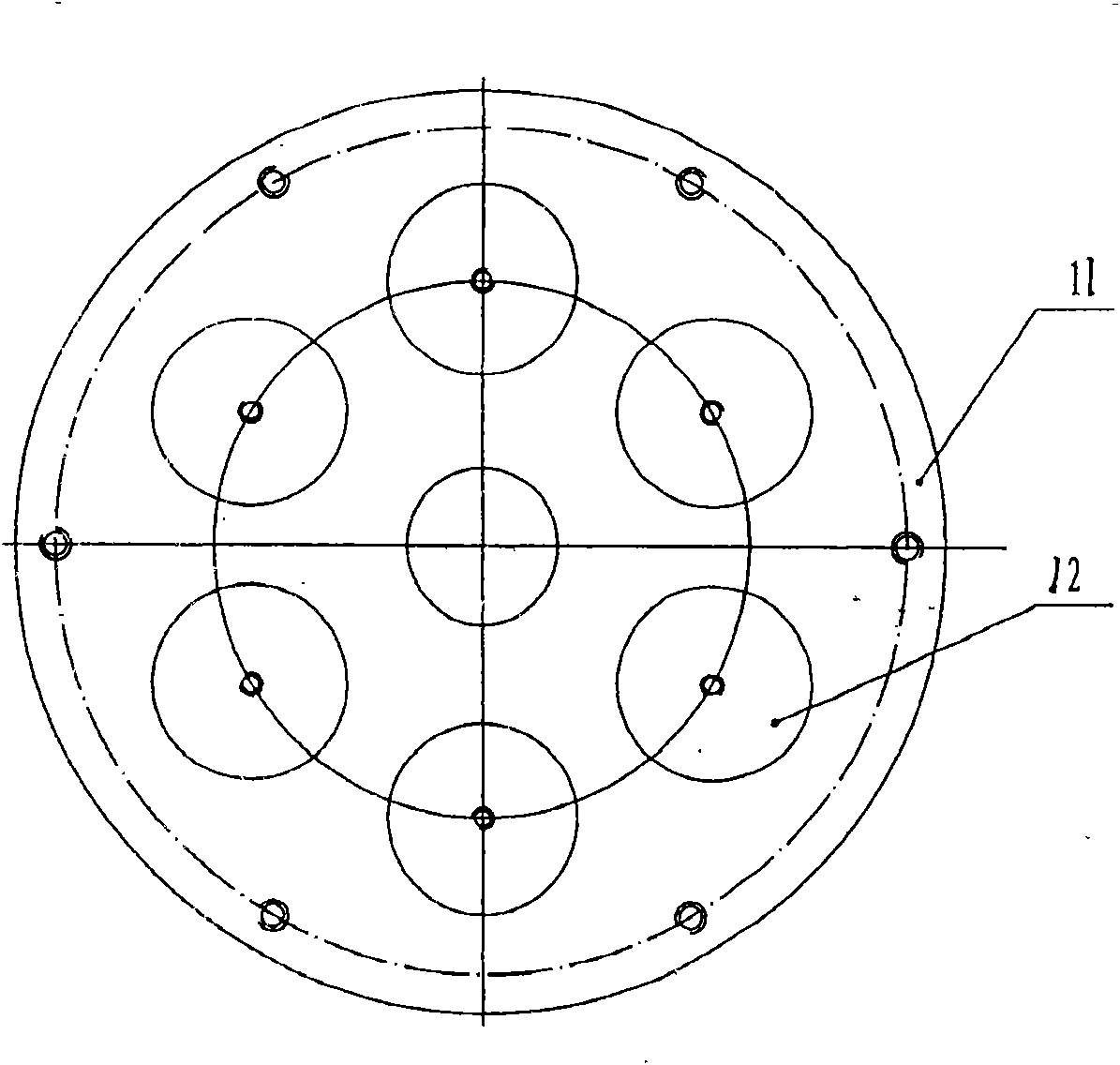

[0015] figure 1 Shown is a special device for magnetic induction heating of the present invention, which is mainly composed of a cylindrical barrel 1, which can be made of metal or other materials. Both ends of the barrel body 1 are provided with barrel covers 2 to form a closed cavity. A rotating shaft 5 is arranged at the center line of the two bucket covers 2, and the rotating shaft 5 is arranged on the two bucket covers 2 through rolling bearings. A metal turbine 8 with a spiral groove 7 is arranged in the middle of the rotating shaft 5. The metal turbine 8 is covered with a metal splint A9.1 on the front and a metal splint B9.2 on the back. The metal splint A9.1 is provided with a spiral Slot 7 communicates with the water eye. A water seal 10 is provided between the outer end of the metal splint A9.1 and the barrel 1, so that two cavities are formed inside the barrel 1. The cavity on the side of the metal splint A9.1 is the water inlet cavity, and the other The side is t...

Embodiment 2

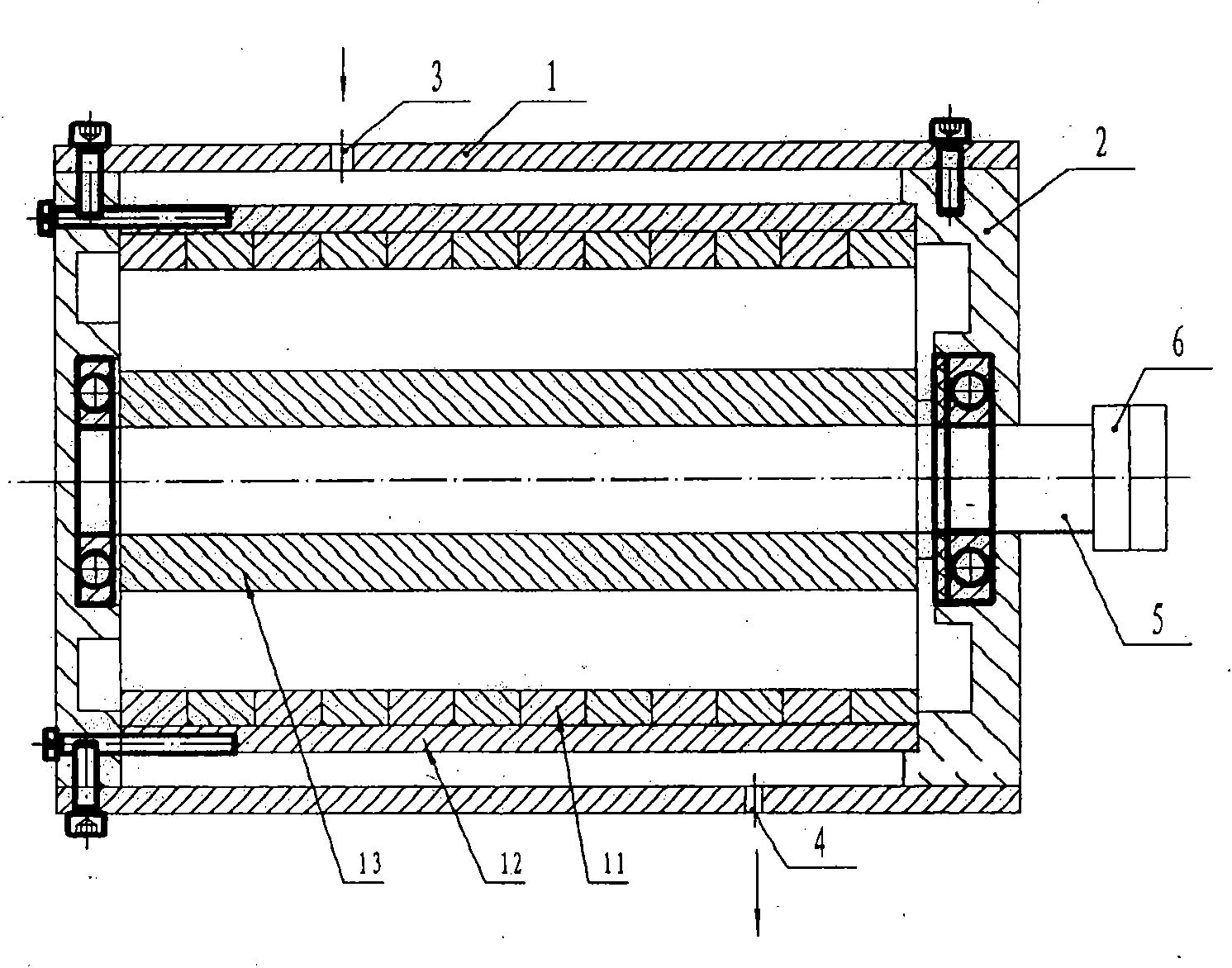

[0018] image 3 Shown here is another special device for magnetic induction heating of the present invention, which is mainly composed of a cylindrical barrel 1 with lids 2 provided at both ends of the barrel 1 to form a closed cavity. A rotating shaft 5 is arranged at the center line of the two bucket covers 2, and the rotating shaft 5 is arranged on the two bucket covers 2 through rolling bearings. A circular barrel-shaped metal barrel 13 is arranged longitudinally on the periphery of the rotating shaft 5, and the metal barrel 13 should have a certain thickness to ensure the cutting force to the magnetic lines of force. The rotating shaft 5 is driven by the external motor 6 to rotate at a high speed through a clutch, thereby driving the metal barrel 13 on it to rotate at a high speed. Such as Figure 4 As shown, arc-shaped permanent magnets are uniformly arranged on the inner wall of the barrel 1 through the magnetic field closing body 12, the magnetic field closing body 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com