Three-phase squirrel-cage AC (alternating current) asynchronous brake motor with high start moment

A braking motor and starting torque technology, applied in asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of inability to start, insufficient starting torque, different material weights, etc., to increase rotor resistance, improve work efficiency, The effect of increasing the starting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

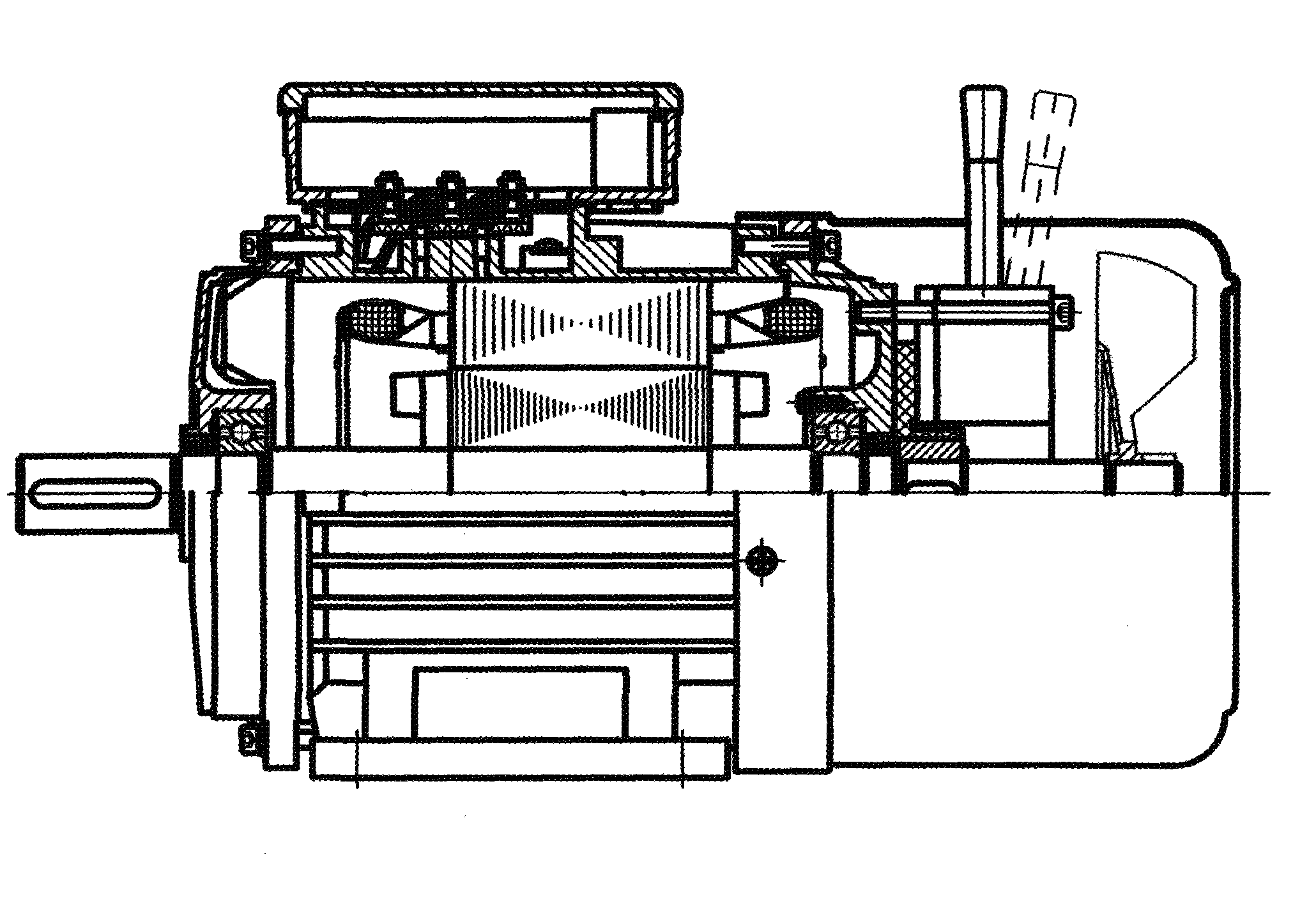

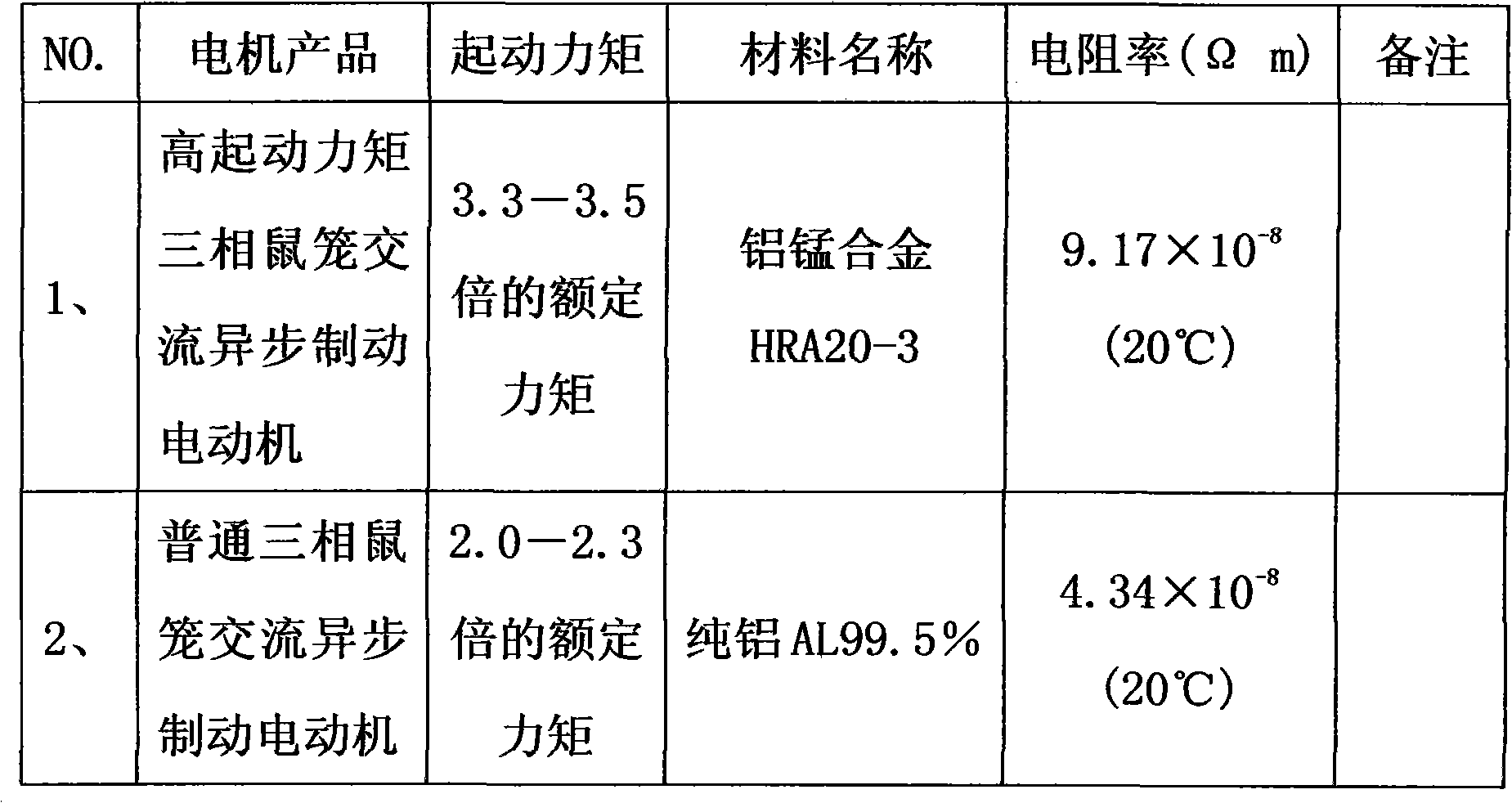

[0007] The electric motor of the present invention is composed of a machine base, a front cover, a rear cover, a stator, a rotor, a main shaft, a brake, a junction box and a fan, and is characterized in that the material of the rotor is machined after casting aluminum-manganese alloy HRA20-3.

[0008] Change the material of the rotor cast aluminum (that is, use high-resistance aluminum) to increase the rotor resistance and increase the starting torque. From the perspective of electromechanics, the electromagnetic torque of the motor is T=m1U1 2 R2 / ΩS((R1+K1R2 / S) 2 +(X1+K1X2) 2 ), the rotating speed is zero when the motor stalls, and now S=1, the electromagnetic torque at this moment is just the stall torque (i.e. starting torque), and the formula becomes: T ST =m1U1 2 R2 / Ω((R1+K1R2) 2 +(X1+K1X2) 2 ), where ml is the number of phases,

[0009] U1 is the voltage,

[0010] R2 is the rotor resistance,

[0011] R1 is the stator resistance,

[0012] S is the slip rate,

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com