Line full section automatic detection system

An automatic detection, full-section technology, used in radio wave measurement systems, measurement devices, electromagnetic wave re-radiation and other directions, can solve the problems of incomplete section parameters, complex algorithms, high cost, and achieve the effect of repeated and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

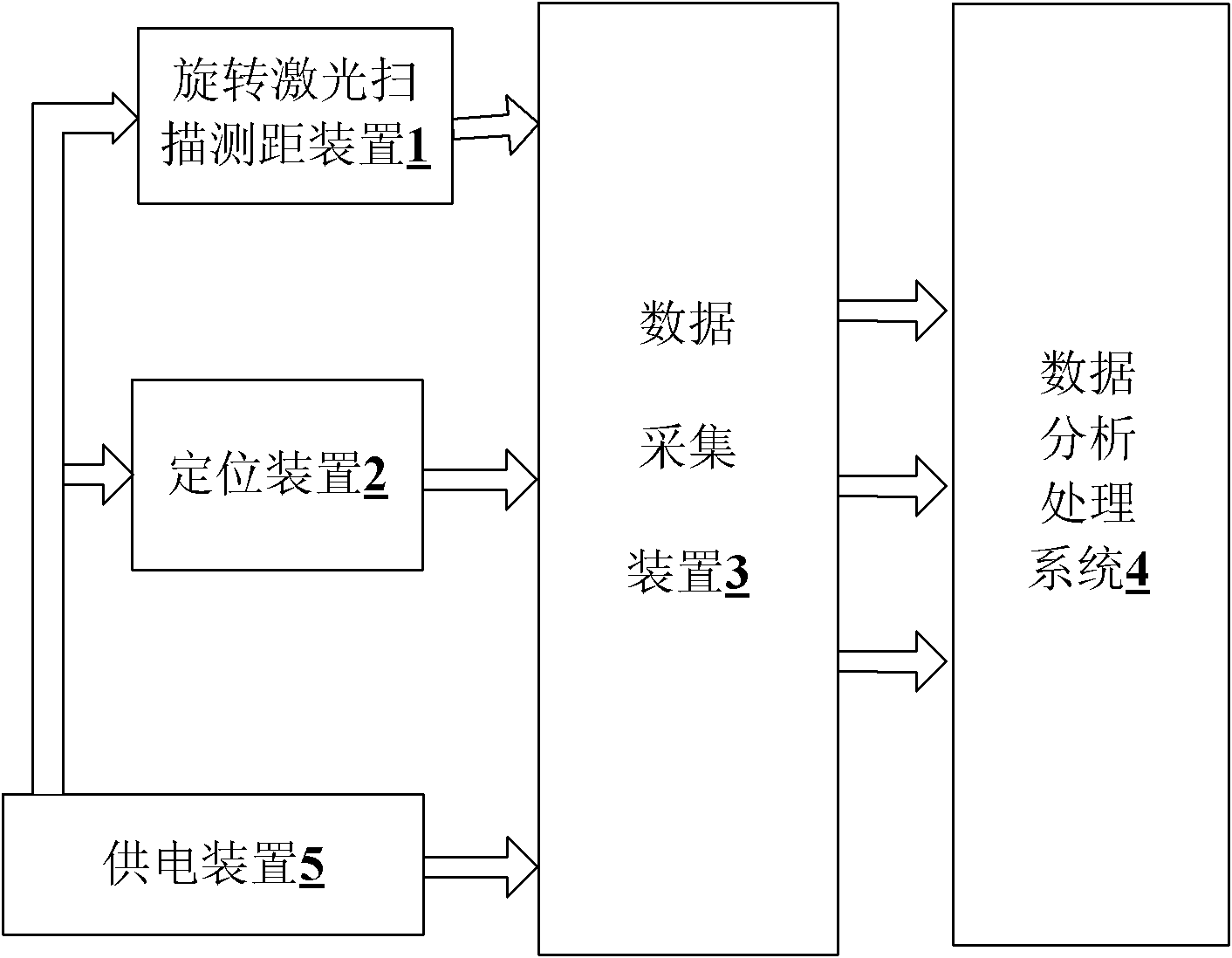

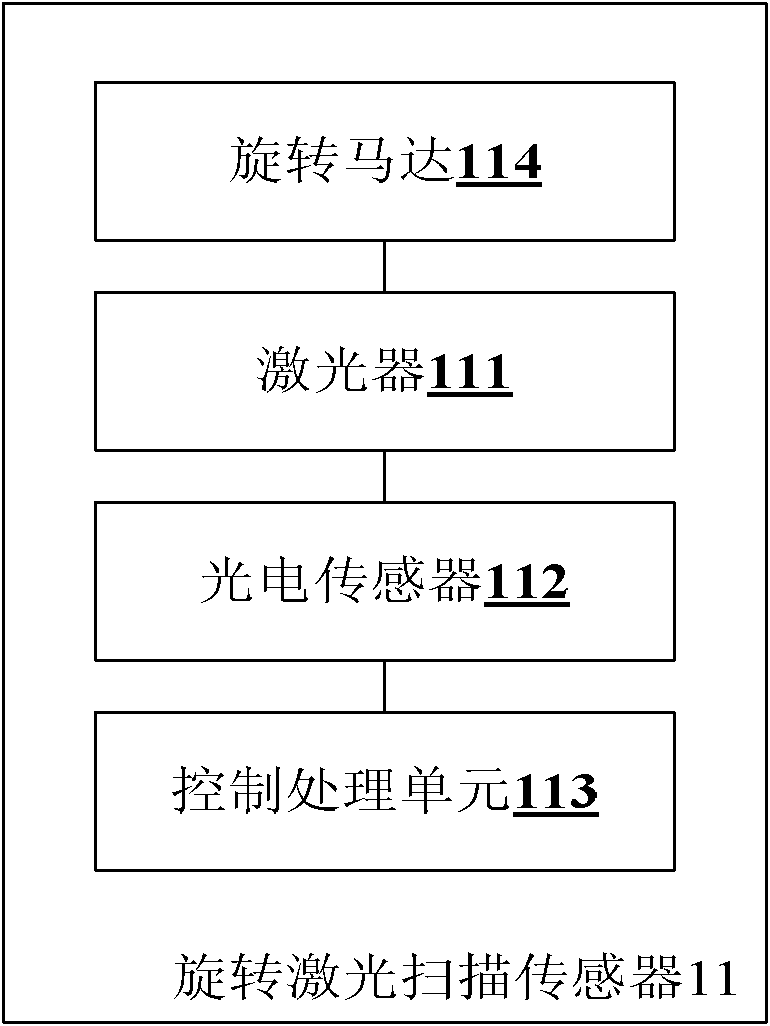

[0022] refer to figure 1 , figure 1 It is a schematic diagram of the hardware connection of the embodiment of the automatic detection system for the full section of the line of the present invention. This embodiment includes: a hand-push mechanical vehicle (not shown) with its own reference, a rotating laser scanning distance measuring device 1, a positioning device 2, a data acquisition device 3, and a data analysis and processing device arranged on the hand-push mechanical vehicle. 4 and power supply device 5; And, rotating laser scanning distance measuring device 1 is arranged on the car body beam that is positioned at line centerline of hand-push mechanical vehicle; Wherein, rotating laser scanning distance measuring device 1 and positioning device 2 are respectively connected with data acquisition The input end of device 3 is connected; the output end of data acquisition device 3 is connected with data analysis and processing device 4; The laser scanning ranging device ...

Embodiment 2

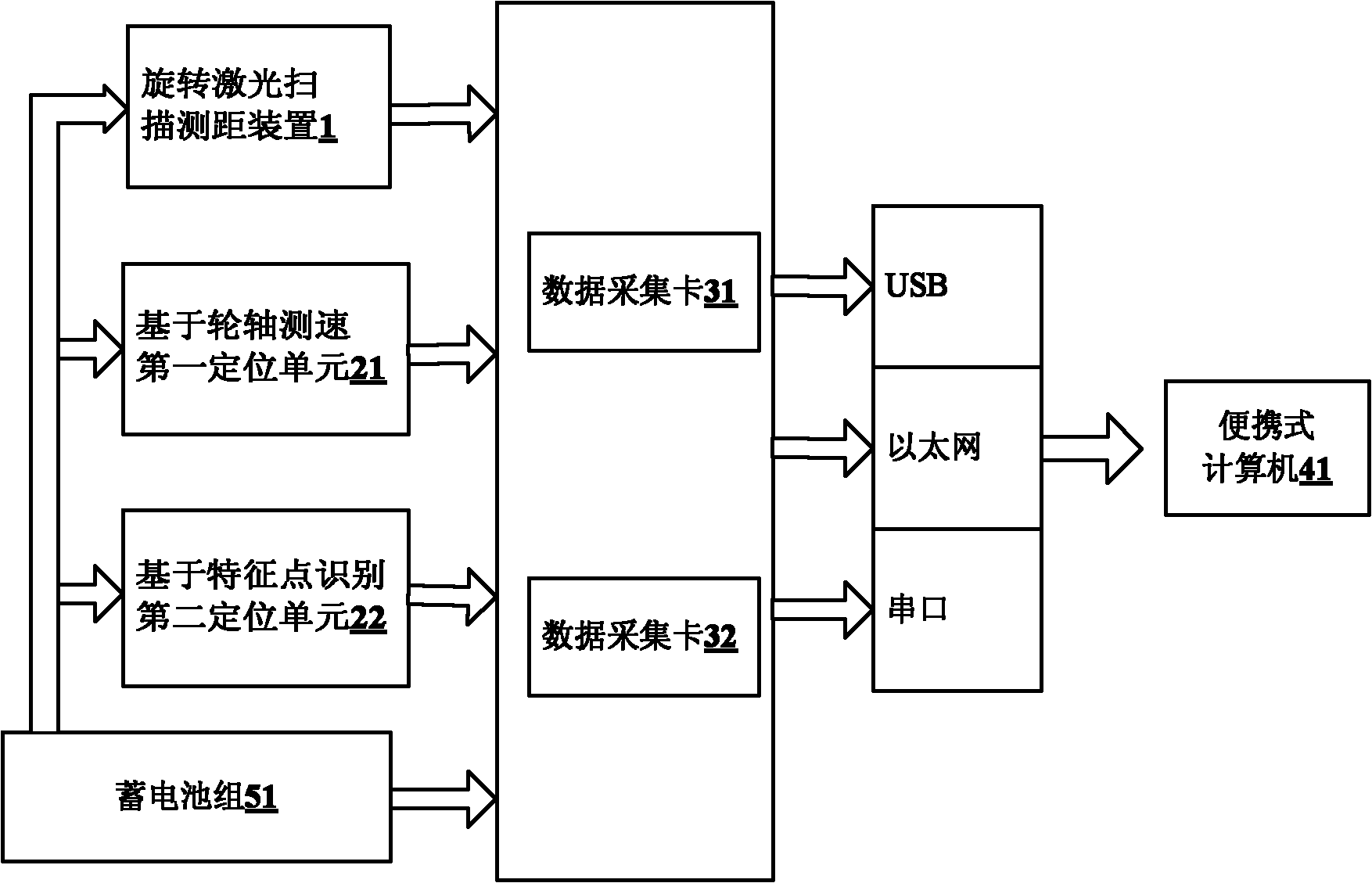

[0030] refer to image 3 , image 3 It is a schematic diagram of hardware connection of another embodiment of the line full-section automatic detection system of the present invention.

[0031]This embodiment includes: a hand-push mechanical car (not shown) with its own reference, a rotating laser scanning distance measuring device 1 arranged on the hand-push mechanical car, a first positioning unit 21 based on wheel axle speed measurement, a first positioning unit 21 based on feature points The identified second positioning unit 22 , the data acquisition device 3 including the data acquisition card 31 and the data acquisition card 32 , the portable computer 41 and the battery pack 51 .

[0032] And, the rotating laser scanning distance measuring device 1 is arranged on the body beam of the hand-push mechanical vehicle located on the center line of the line; wherein, the rotating laser scanning distance measuring device 1, the first positioning unit 21 based on wheel axle spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com