Quality control method of pulean preparation

A detection method and Pulean technology, applied in the field of quality control of Pulean preparations, can solve the problems of poor quantification and lack of α-linolenic acid, and achieve control of internal quality, good reliability, and precise testing. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

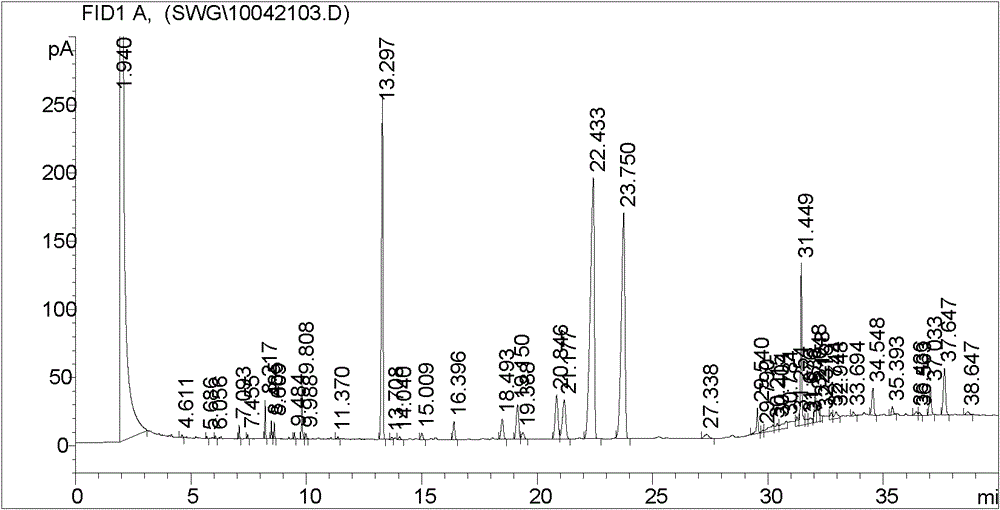

[0036] Example 1: Assay

[0037] 1. Method

[0038] (1) Preparation of test solution: Take 20 Pulean capsules (batch number: 20090402), grind finely, weigh 0.5g, accurately weigh, place in a stoppered conical flask, add 50ml petroleum ether (60-90 ℃) Ultrasonic extraction for 1 hour, suction filter with triangular suction filter, wash the funnel and filter paper with a small amount of petroleum ether, put the filter residue and filter paper in an Erlenmeyer flask, continue to extract 2 times, and use 50ml petroleum ether for the second ultrasonic extraction for 1 hour. The third ultrasonic extraction with 30ml petroleum ether for 0.5 hours, suction filtration after each extraction, wash the funnel and filter paper with a small amount of petroleum ether, combine the filtrate, recover the solvent under reduced pressure at 60℃ to dryness, add sulfuric acid methanol-benzene to the residue (weight ratio 1:1) 10ml, reflux in a water bath at 60°C for 30 minutes, let cool, add 10ml of n-h...

Embodiment 2

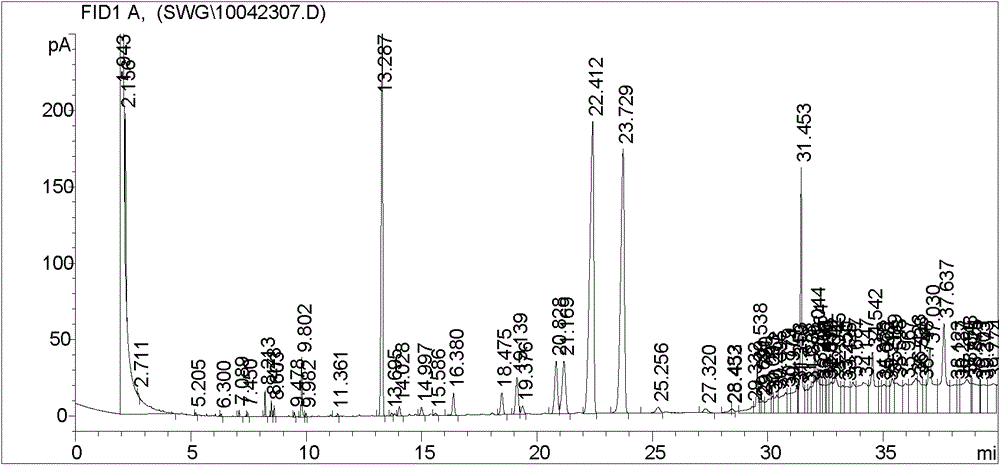

[0045] Example 2: Assay

[0046] 1. Method

[0047] (1) Preparation of the test solution: Take 20 tablets of Pro'an (batch number: 20090422), grind them into fine pieces, weigh 0.5g, accurately weigh, and place in a stoppered conical flask, add 50ml petroleum ether (60- 90℃) Ultrasonic extraction for 1 hour, then filter with triangular suction filter, wash the funnel and filter paper with a small amount of petroleum ether, put the filter residue and filter paper in an Erlenmeyer flask, continue the extraction 2 times, and use 50ml petroleum ether for the second ultrasonic extraction for 1 hour For the third time, use 30ml petroleum ether for ultrasonic extraction for 0.5 hours. After each extraction, filter with suction. Wash the funnel and filter paper with a small amount of petroleum ether. Combine the filtrate. Recover the solvent under reduced pressure at 60℃ to dryness. Add sulfuric acid methanol-benzene to the residue. Ratio 1:1) 10ml, reflux in a water bath at 60℃ for 30 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com