Digital brinell hardness tester

A Brinell hardness tester and display technology, applied in the direction of testing the hardness of materials, etc., can solve the problems of large noise, display screen shake, small force inaccuracy of Brinell hardness tester, etc., to achieve accurate test force, simple operation interface and easy operation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

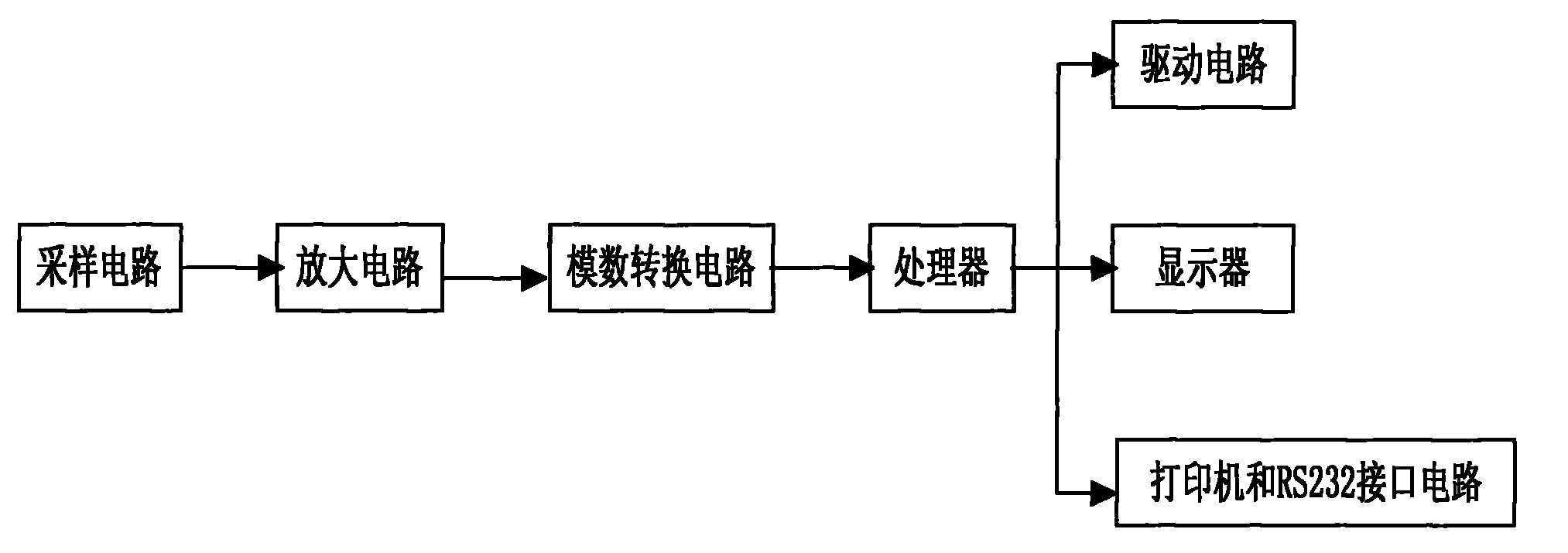

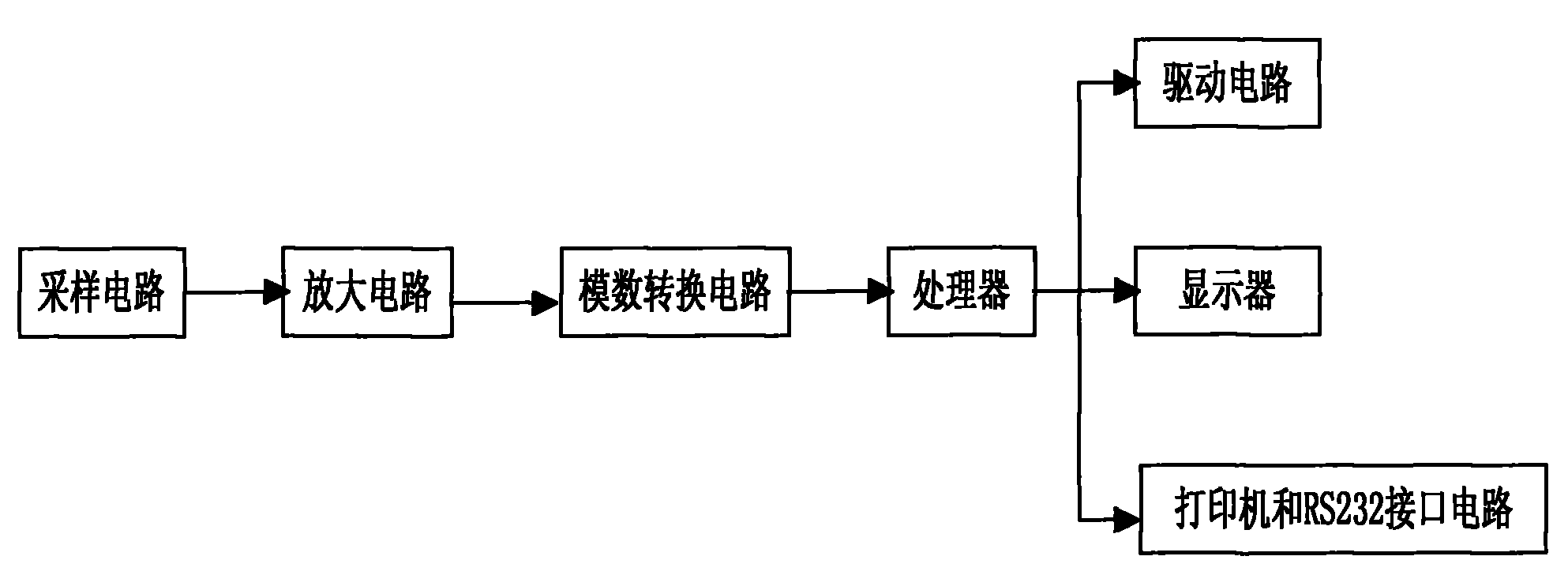

[0018] like figure 1 As shown, the digital display Brinell hardness tester of the present invention comprises modules such as sampling circuit, amplifying circuit, analog-to-digital conversion circuit, processor, drive circuit, display, printer and RS232 interface circuit, and the function of each module is as follows:

[0019] Sampling circuit: it collects the analog signal of the pressure sensor with a sensitivity of 2mV and a precision of 0.05%, and transmits it to the amplifying circuit.

[0020] Amplifying circuit: it is connected with the sampling circuit and amplifies the collected analog signal to the analog-to-digital conversion circuit.

[0021] Analog-to-digital conversion circuit: it is connected with the amplifier circuit and adopts the AD0832 analog-to-digital conversion chip, which converts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com