Dry yarn winding forming method for pressure container

A technology of winding molding and pressure vessels, applied in the field of composite material molding technology, can solve the problems of not using large-scale industrial production, complex molding technology, long production cycle, etc., achieve significant economic and social benefits, simple implementation and control process , The effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

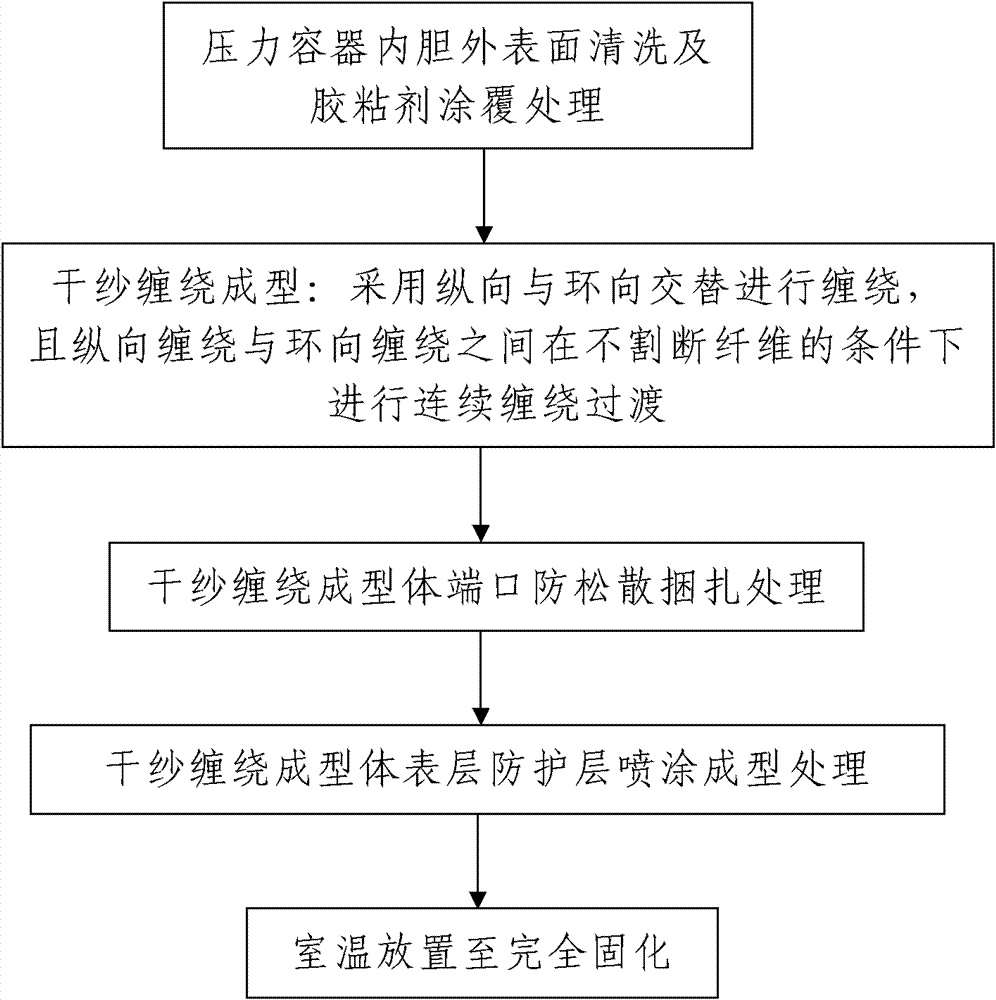

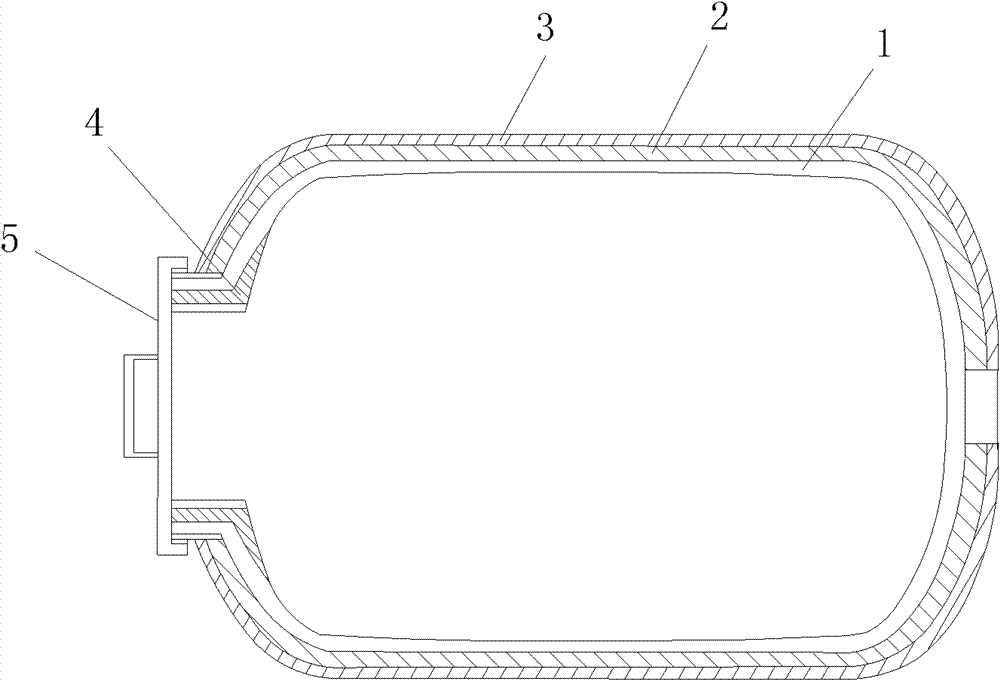

[0047] Firstly, according to the structure and size of the inner tank of the pressure vessel to be wound and the performance and weight requirements of the product to be formed, combined with the bulk performance of the fiber dry yarn used for winding, the winding forming process parameters in the dry yarn winding forming process were manually designed and compared. Input the designed winding forming process parameters into the control host of the winding machine, and at the same time compile the combined angle gradual change control program according to the converted winding forming process parameters. According to the continuous winding requirements, the control host will change the combined angle gradually The control program realizes the continuous transition between longitudinal winding and hoop winding, ensuring the continuity of the carbon fiber winding process. Secondly, prepare epoxy resin adhesive according to the ratio of epoxy resin (618): triethylenetetramine=100: ...

Embodiment 2

[0051] In this embodiment, first, according to the structure and size of the pressure vessel liner to be wound and the performance and weight requirements of the product to be formed, combined with the bulk performance of the dry fiber yarn used for winding, the winding during the winding and forming process of the dry yarn is artificially designed. The forming process parameters and the designed winding forming process parameters are input into the control host of the winding machine. At the same time, the combined angle gradient control program is compiled according to the converted winding forming process parameters. The combined angle gradient control program realizes the continuous transition between longitudinal winding and hoop winding, ensuring the continuity of the aramid fiber winding process. Secondly, prepare the polyurethane adhesive according to the ratio of polyurethane: polyurethane rubber vulcanizing agent (MOCA)=90: 30~38 according to the mass ratio; clean the...

Embodiment 3

[0053]In this embodiment, first, according to the structure and size of the pressure vessel liner to be wound and the performance and weight requirements of the product to be formed, combined with the bulk performance of the dry fiber yarn used for winding, the winding during the winding and forming process of the dry yarn is artificially designed. The forming process parameters and the designed winding forming process parameters are input into the control host of the winding machine. At the same time, the combined angle gradient control program is compiled according to the converted winding forming process parameters. The combined angle gradient control program realizes the continuous transition between longitudinal winding and hoop winding, ensuring the continuity of the PBO fiber winding process. Secondly, prepare polyurethane adhesive according to the mass ratio of unsaturated polyester: MOCA=90:5; then clean the outer surface of the pressure vessel liner 1 (specifically po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com