Tool for processing burrs at through position of through hole

A technology of intersecting holes and tools, applied in the field of mechanical processing, can solve problems such as large fluctuations, unfavorable mass production, and impact on product quality, and achieve the effects of high processing efficiency, consistency, and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

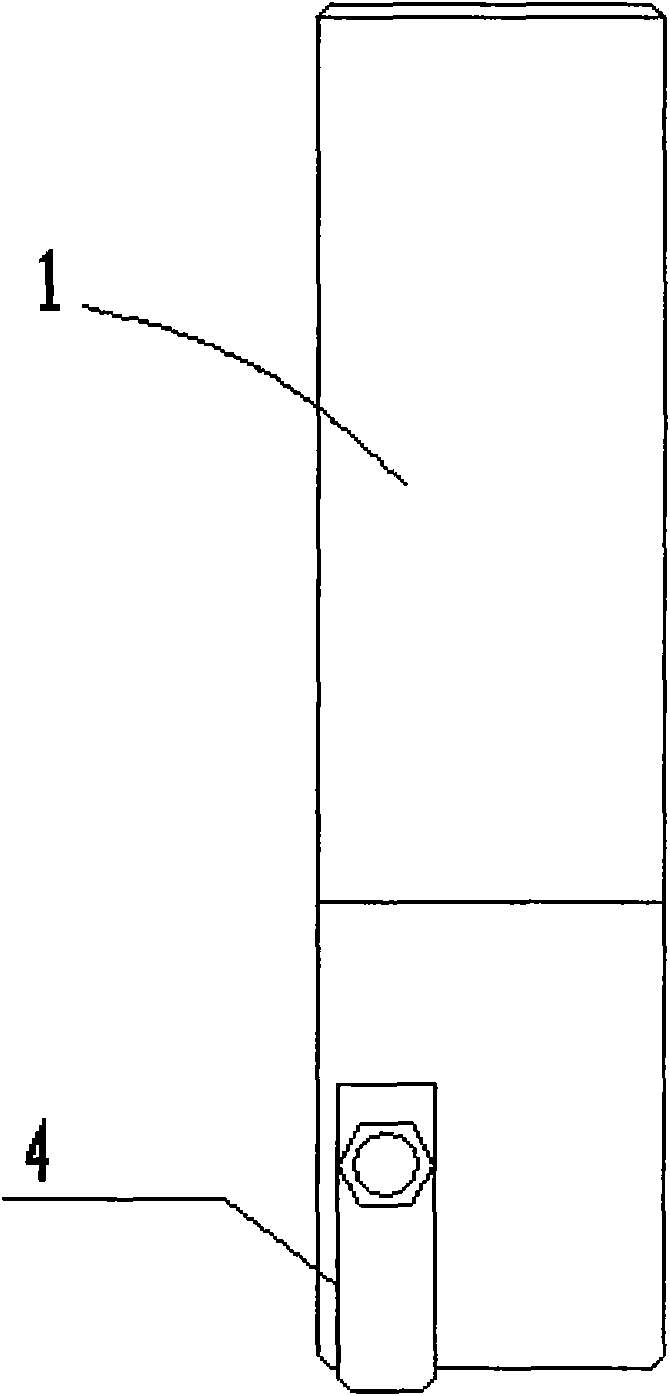

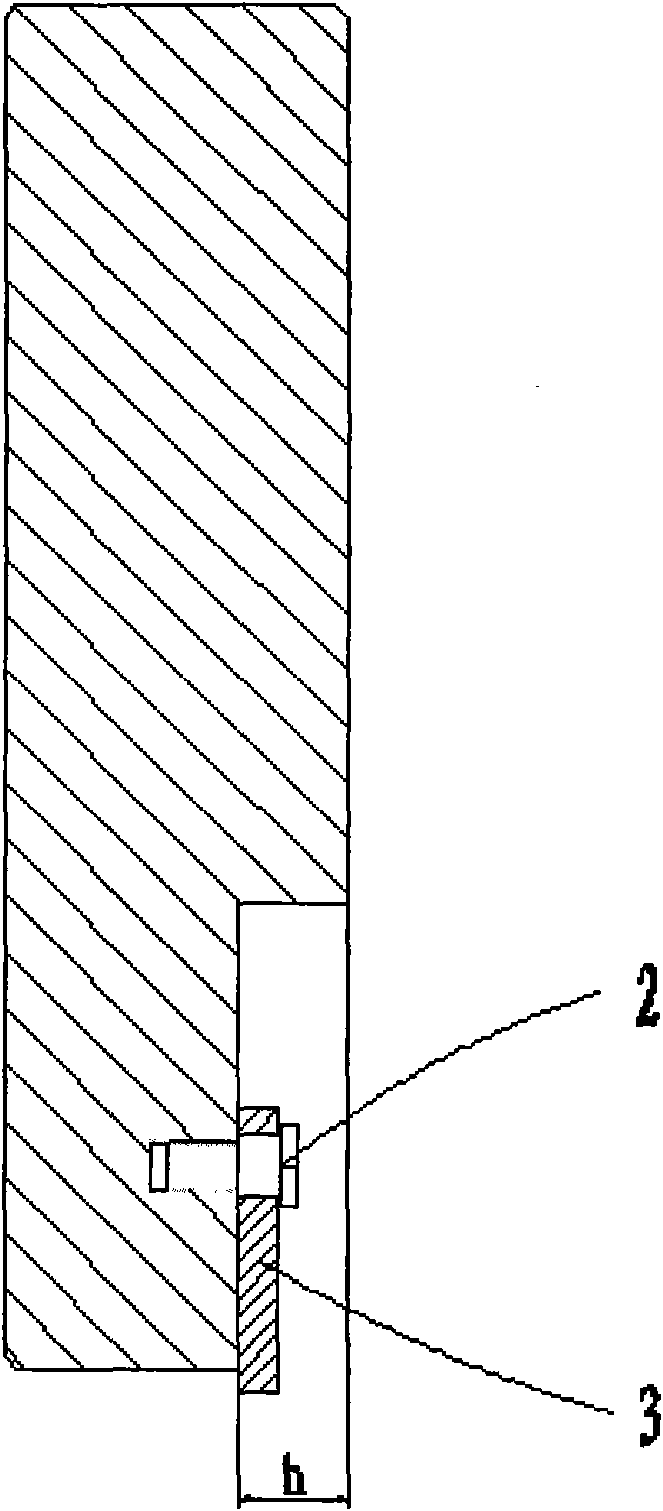

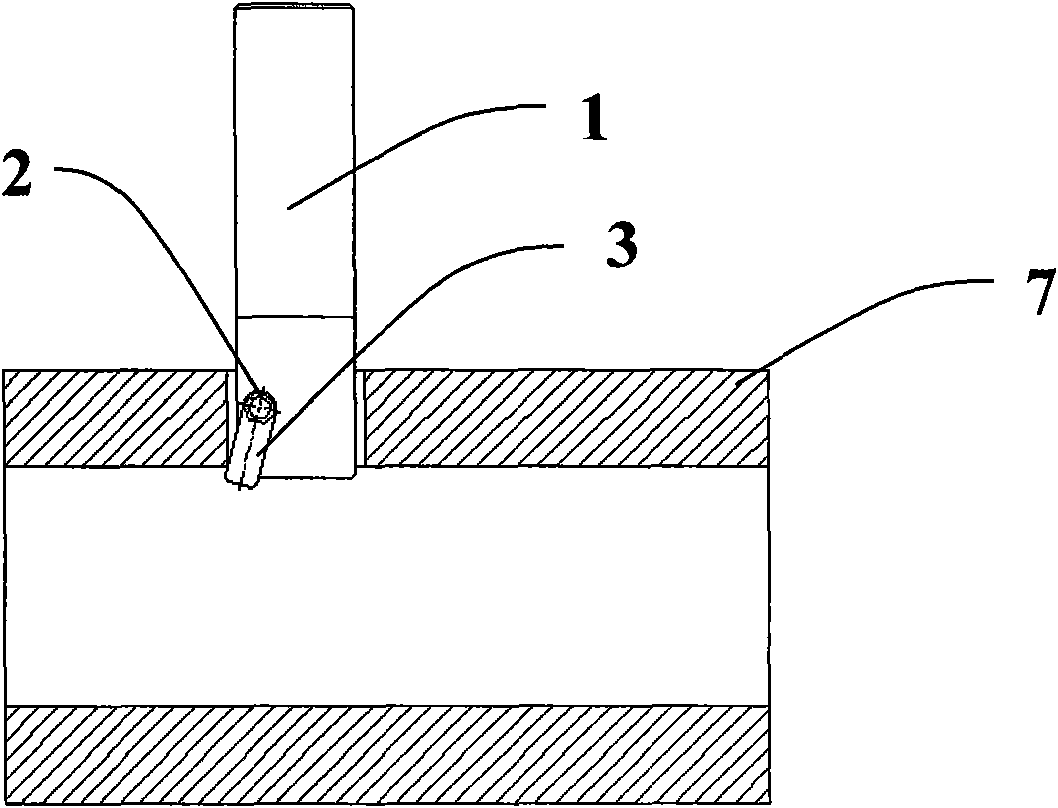

[0027] Such as Figure 1~4 As shown, a tool for processing burrs at the intersection of intersecting holes is mainly composed of a tool body 1, a cutting body 3 and a connecting screw 2. The material hardness of the tool body 1 is 23HRC, the shape of the tool body 1 is a cylinder, the outer diameter of the cylindrical tool body 1 is 4.8mm, and the length of the cylindrical tool body is 50mm. The outer diameter accuracy of the cylindrical tool body 1 is h7, and the roughness is Ra0.4; the cylindrical tool body 1 is vertically placed in the intersecting hole of the processed intersecting hole part 7, and the upper end of the cylindrical tool body 1 40mm is connected with the processing equipment. A plane is cut at 10 mm on the outer surface of the lower end of the cylindrical tool body 1, and the plane is parallel to the axis of the tool body 1, and the cutting depth h of the plane is 2 mm; a threaded hole is provided on the plane, and the The distance between the center line ...

Embodiment 2

[0031]A tool for processing burrs at the intersections of intersecting holes, the same as in Example 1, wherein: the material hardness of the tool body 1 is 33HRC, the outer diameter of the cylindrical tool body 1 is 100mm, and the cylindrical The length of the tool body 1 is 150 mm, the outer diameter accuracy of the cylindrical tool body 1 is h6, and the roughness is Ra0.4; it is connected with the processing equipment at 50 mm from the upper end of the cylindrical tool body 1; 1. Cut 4 planes at 40mm on the outer surface of the lower end, and the 4 planes are all parallel to the tool body 1 axis. The cutting depth h of the planes is 10mm; a threaded hole is provided on each plane, and the thread The distance between the centerline of the hole and the axis of the tool body 1 is 10mm.

[0032] The material hardness of the cutting body 3 is 58HRC, the length of the cutting body 3 is 30 mm, the width of the cutting body 3 is 5 mm, and the height of the cutting body 3 is 5 mm. ...

Embodiment 3

[0035] A tool for processing burrs at the intersections of intersecting holes, the same as in Example 1, wherein: the material hardness of the tool body 1 is 43HRC, and the shape of the tool body 1 is a cylinder 6, and the cylindrical tool body The outer diameter of 1 is 190 mm, the length of the cylindrical tool body 1 is 200 mm, the outer diameter accuracy of the cylindrical tool body 1 is h6, and the roughness is Ra0.4; at 60 mm from the upper end of the cylindrical tool body 1 Connect with the processing equipment; cut 8 planes at 140 mm on the outer surface of the lower end of the cylindrical tool body 1, and the cutting depth h of the planes is 20 mm; a threaded hole is provided on each plane, and the threaded hole The distance between the centerline and the axis of the tool body 1 is 20mm.

[0036] The material hardness of the cutting body 3 is 65HRC, the length of the cutting body 3 is 140 mm, the width of the cutting body 3 is 10 mm, and the height of the cutting body...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com