Carbide slag slurry filtering process and self-cleaning filter

A self-cleaning filter, calcium carbide slurry technology, applied in fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problem of low work efficiency, unsatisfactory separation effect of large particles, and inability to effectively carry out metal particles. separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

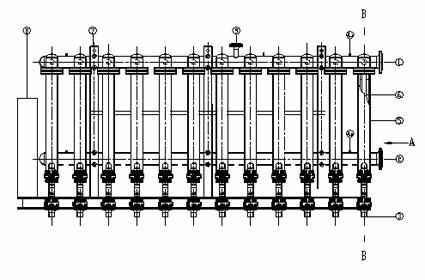

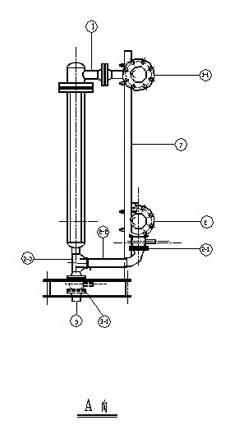

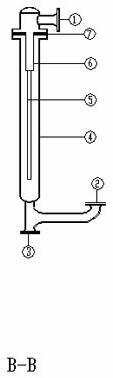

[0021] The present invention aims at the characteristics of strong plasticity and agglomeration of particles in calcium carbide slag slurry, and needs to meet the two-way index requirements of precise control of particle size and solid content of filtrate, and realize the working requirements of large flow, continuous online, and low manual workload. The key point is to solve the key problems of precise filtration, online backwash regeneration, and automatic sewage (slag) discharge.

[0022] The overall technical scheme of the equipment is as follows:

[0023] The technological process of the present invention is divided into four processes of filtration-formation of filter cake-backwash regeneration-blower discharge. The equipment adopts the filter element made of metal material. By adjusting the precision of the filter element, the solid particles that need to be removed in the carbide slurry are effectively intercepted, and the solid particles that need to be retaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com