Energy-saving boiler

An energy-saving pot and section pot technology, applied in the fields of energy-saving steamers and energy-saving stew pots, can solve the problems of little difference in structure, low heat exchange efficiency, improved thermal efficiency, etc., and achieve the advantages of beautiful appearance, fuel saving and CO2 emission reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

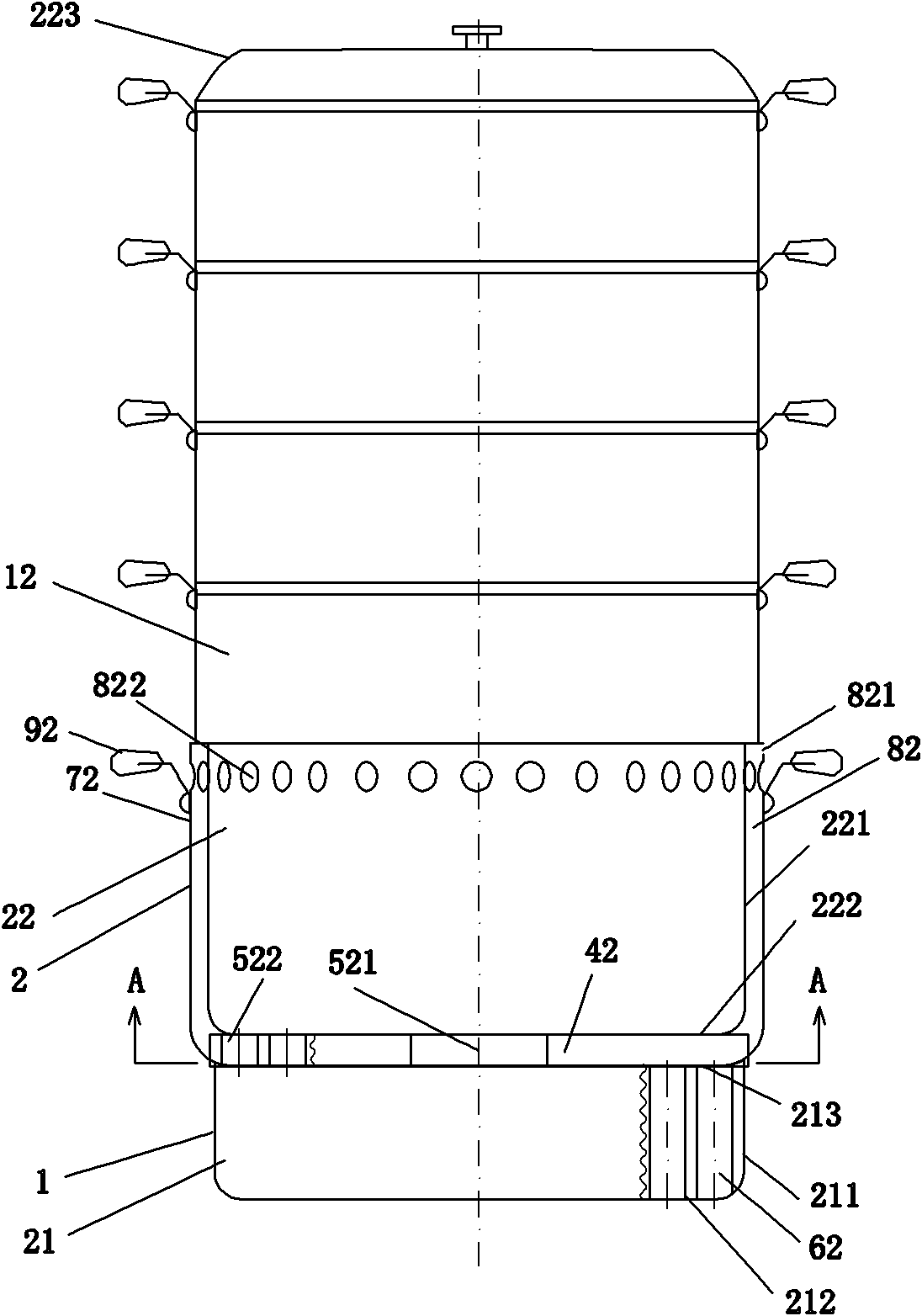

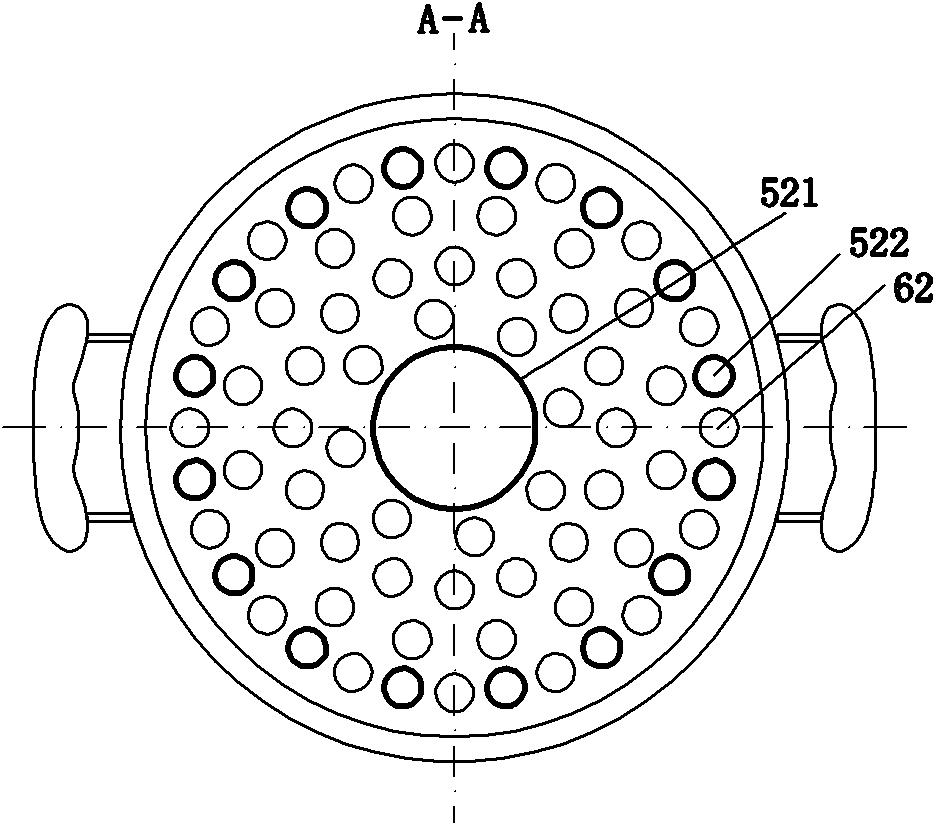

[0017] Embodiment 1, two-stage energy-saving steamer. refer to figure 1 , figure 2 The pot body 1 of the second-stage energy-saving steamer includes a lower pot 21 and an upper pot 22, an annular cavity 42 is arranged between the top surface 213 of the lower pot 21 of the second-stage pot 2 and the bottom surface 222 of the upper pot 22, and the lower pot 21 Between the upper pot 22, a central connecting pipe 521 and 16 communicating pipes 522 uniformly distributed around the outermost circle of the central axis are provided along the central axis of the pot. Outside the shell 221 of the upper pot 22 of the second pot, Outer ring 72 with equal gap with pot shell 221, handle 92 is arranged on the upper part of outer ring 72, outer ring 72 communicates with annular cavity 42 to form flue gas heat flow heat exchange discharge channel 82, and its outlet end is provided with open outer outer ring exhaust Port 821 or a plurality of closed side exhaust holes 822 uniformly distribu...

Embodiment 2

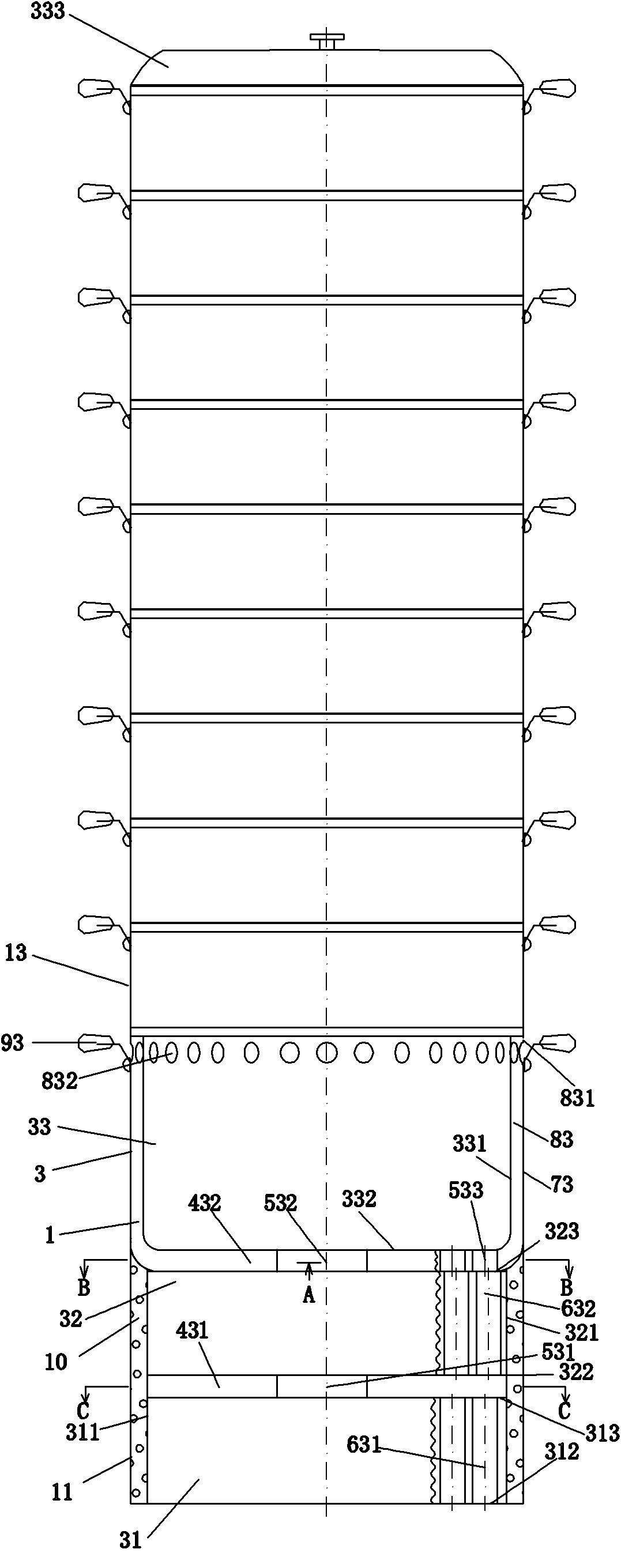

[0018] Embodiment 2, a three-stage energy-saving steamer. refer to Figure 3~Figure 6 , the pot body 1 of the three-stage energy-saving steamer is set into three-stage pot 3; the three-stage pot 3 is provided with a lower pot 31, a middle pot 32 and an upper pot 33, and the top surface 313 of the lower pot 31 and the bottom surface of the middle pot 32 322 are provided with a lower annular cavity 431 and a lower connecting pipe 531 along the central axis of the pot; an upper annular cavity 432 is provided between the top surface 323 of the middle pot 32 and the bottom surface 332 of the upper pot 33, and the middle pot 32 and the upper pot 33 along the central axis of the pot are provided with a central upper connecting pipe 532 and 16 upper connecting pipes 533 evenly distributed around the outermost circle of the central axis; Outer ring 73 with the same gap as shell 331, pot handle 93 is arranged on the upper part of outer ring 73, and outer ring 73 communicates with upper...

Embodiment 3

[0019] Embodiment 3, two-stage energy-saving stewing pot. refer to Figure 7 , compared with embodiment 1, the pot body 1 of the two-stage energy-saving stewing pot is correspondingly the same as in embodiment 1, and a stewing pot 14 and a pot cover 223 are arranged in the upper pot 22 to form a two-stage energy-saving stewing pot .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com