Bowling ball surface treatment machine and bowling ball surface treatment method

A surface treatment machine and surface treatment technology, applied to bowling balls, spherical grinders, ball games, etc., can solve problems such as easy problems, high cost, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

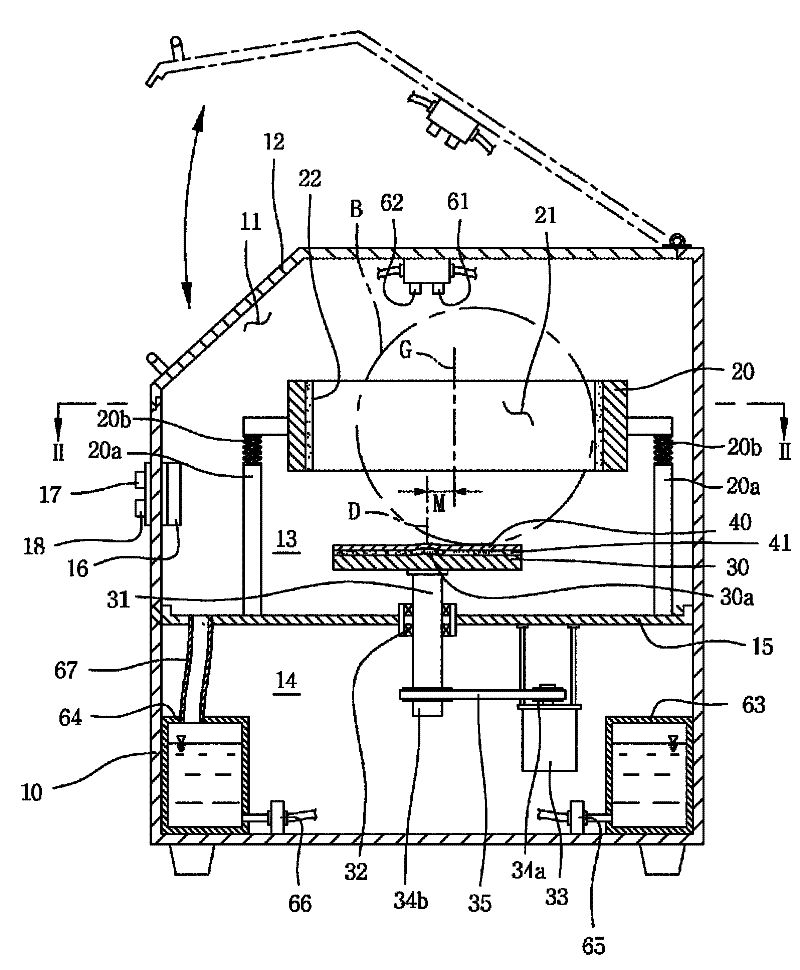

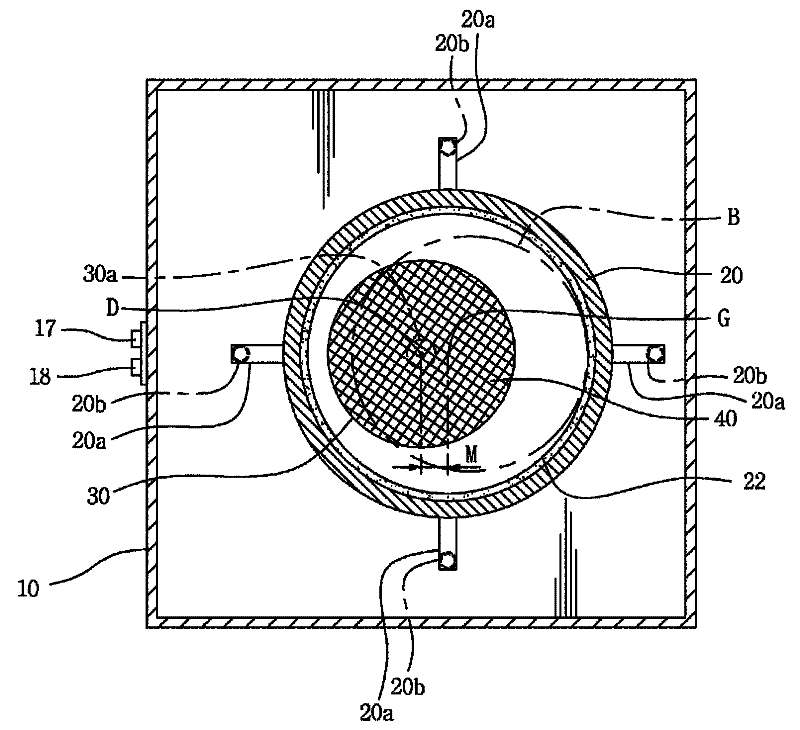

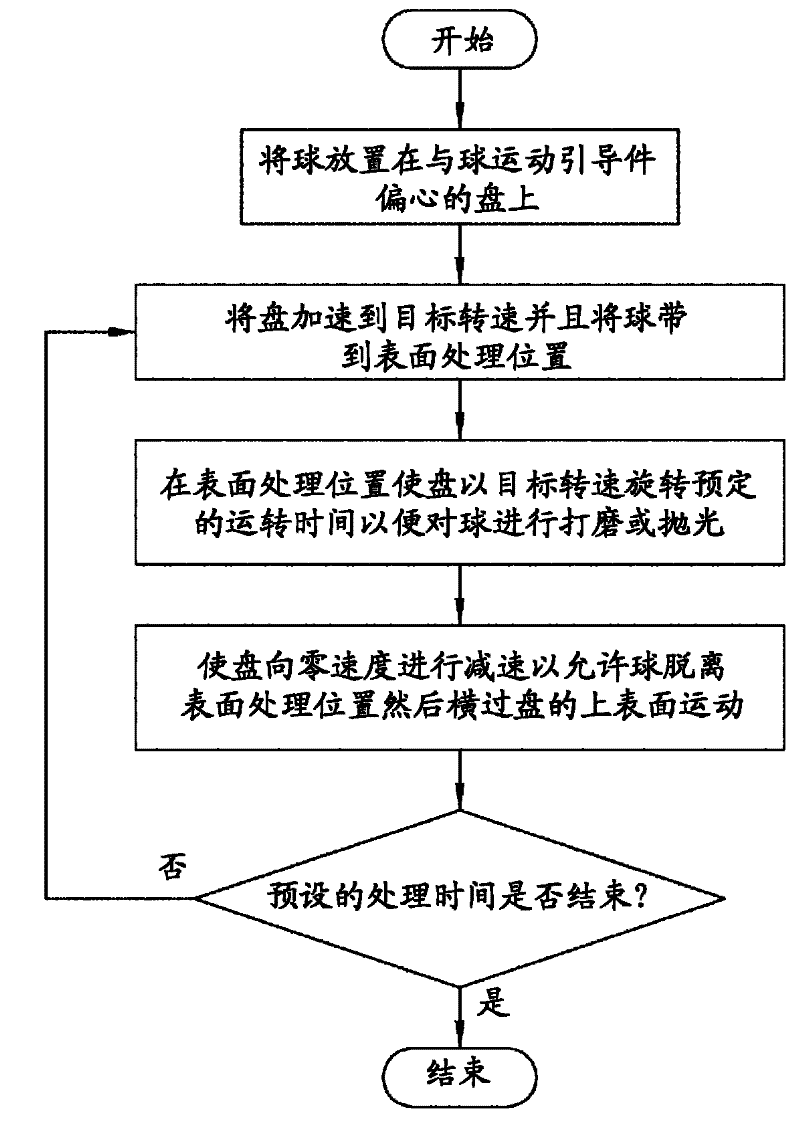

[0030] Preferred embodiments of the bowling ball surface treatment machine and method according to the present invention will now be described in detail with reference to the accompanying drawings.

[0031] refer to figure 1 and figure 2 , The bowling ball surface treatment equipment includes a housing 10 with a top inlet 11 through which bowling balls B are put into the housing 10 or taken out from the housing 10 . The inlet 11 is openably closed by a cover 12 . The housing 10 has an inner space divided into an upper surface treatment chamber 13 and a lower driving chamber 14 by a partition 15 . Through the surface treatment chamber 13, the bowling ball B is subjected to surface treatment such as grinding, polishing and the like. The drive chamber 14 is designed to house a drive unit described later.

[0032] A controller 16 for controlling the operation of the bowling ball finisher is attached to the inner side surface of the housing 10 . A series of buttons 17 and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com