Liquid level measurement and control training system and operation method thereof

A technology of liquid level detection and liquid level, which is applied in the field of liquid level measurement and control training system, can solve problems such as difficulty in following up the development of professional technology, single structure, and few functions, and achieve easy understanding and acceptance, strong expandability, and training Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

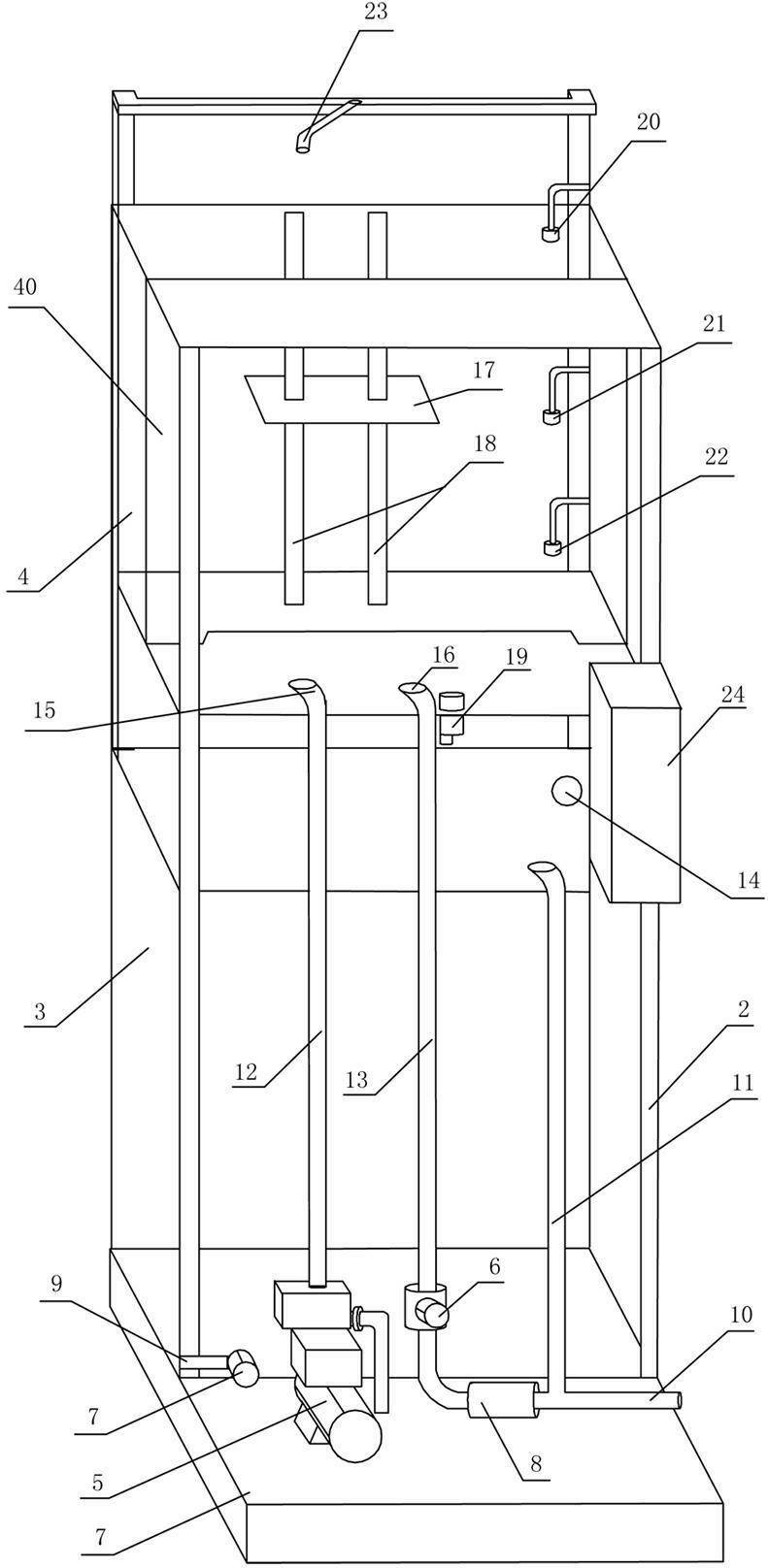

Image

Examples

Embodiment 1

[0036] Embodiment 1. Liquid level open-loop control mode controlled by switching value

[0037] The operation steps include:

[0038]Step 1: Determine that the training content is the liquid level open-loop control mode of switch value control.

[0039] Step 2: The main hardware of the electrical system used in the liquid level open-loop control mode controlled by the switch includes the control button 39, the AC contactor 30, the water pump motor 5, the programmable logic controller PLC 31, the air switch 27 and the drainage solenoid valve 6, etc. .

[0040] Step 3: Set up a program on the programmable controller PLC31 to read the position information of the upper liquid level detection sensor 20 , the middle liquid level detection sensor 21 and the lower liquid level detection sensor 22 .

[0041] Step 4: Close the air switch 27, turn on the power supply, and the power indicator light 28 lights up. Run the program, press the start button in the control button 39, the whol...

Embodiment 2

[0045] Embodiment 2. Liquid level closed-loop control mode controlled by analog quantity

[0046] The operation steps include:

[0047] Step 1: Determine that the training content is the liquid level closed-loop control mode of analog quantity control.

[0048] Step 2: The main hardware of the electrical system used in the liquid level closed-loop control mode of analog quantity control includes control buttons 39, AC contactor 30, water pump motor 5, programmable logic controller PLC31, analog-to-digital converter ADC32, and digital-to-analog converter DAC33, touch screen 36, frequency converter 35, pressure sensor 19, drain solenoid valve 6, etc. Set the operating parameters of the inverter 35, and the frequency of the inverter 35 adopts the analog given mode.

[0049] Step 3: Set the program on the programmable logic controller PLC31, and set the target liquid level value, the upper limit liquid level value and the lower limit liquid level value on the touch screen 36 res...

Embodiment 3

[0054] Embodiment 3. Liquid level closed-loop control mode of communication control

[0055] The operation steps include:

[0056] Step 1: Determine that the training content is the liquid level closed-loop control mode of communication control.

[0057] Step 2: The main hardware of the electrical system used in the liquid level closed-loop control mode of communication control includes AC contactor 30, water pump motor 5, programmable logic controller PLC 31, touch screen 36, frequency converter 35, ultrasonic positioning probe 23, and intelligent control module MCU34, communication cable and drain solenoid valve 6, etc.

[0058] The operating parameters and communication protocol parameters of the frequency converter 35 are set, and the output frequency of the frequency converter 35 adopts a communication given mode.

[0059] Step 3: Set the programmable controller PLC31 program, and set the target liquid level value, the upper limit liquid level value, and the lower limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com