High-power LED illumination lamp metal radiator and manufacturing method

A technology of LED lighting lamps and metal heat sinks, applied in the field of lighting, can solve the problems of heavy weight, waste, large volume, etc., and achieve the effects of convenient application, reduction of consumption, and improvement of heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

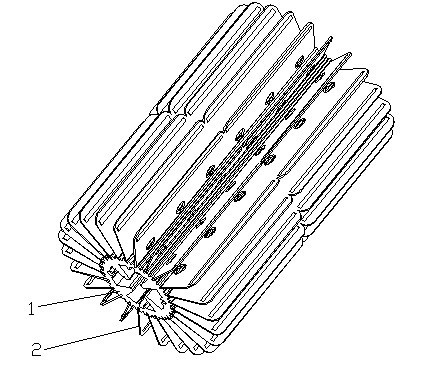

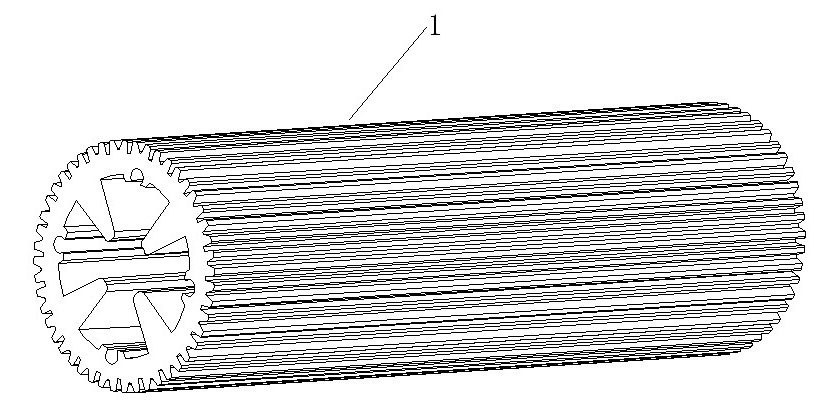

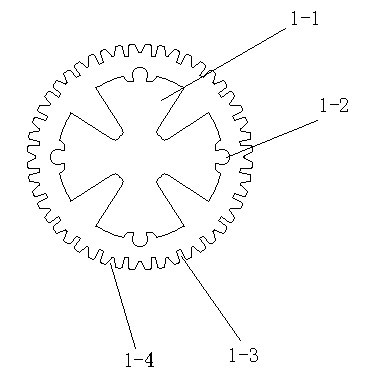

[0024] Such as Figure 1 to Figure 4 As shown, a metal radiator of a high-power LED lighting lamp includes a cooling shaft 1 and a cooling fin 2. The cooling shaft 1 is a cylinder, and a through hole 1-1 is provided at the center of the cylinder. The end surface is correspondingly provided with positioning holes 1-2 connected at both ends, and several U-shaped insert grooves 1-3 and an equal number of V-shaped sheet-pressing grooves 1-4 are uniformly arranged on the circumferential surface of the heat dissipation shaft 1. Shape insert groove 1-3 and V-shaped sheet pressing groove 1-4 are arranged at intervals; Heat sink 2 is a rectangular sheet shape, and its upper end two angles are symmetrical arc angles 2-1, set on the face of heat sink 2 There are several rectangular reinforcing grooves 2-2 and several heat dissipation holes 2-3; the lower ends of several heat dissipation fins 2 are squeezed into several U-shaped insert grooves 1-3 on the heat dissipation shaft 1 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com