Soil monolith acquisition and production equipment and technology

A technology for specimen collection and manufacturing process, which is applied in the preparation of test samples and sampling devices, etc. It can solve the problems of specimen damage, mechanical material falling off, easy fracture, collapse, etc., and achieve large exhibition area, light weight and high strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] 1. Field collection stage:

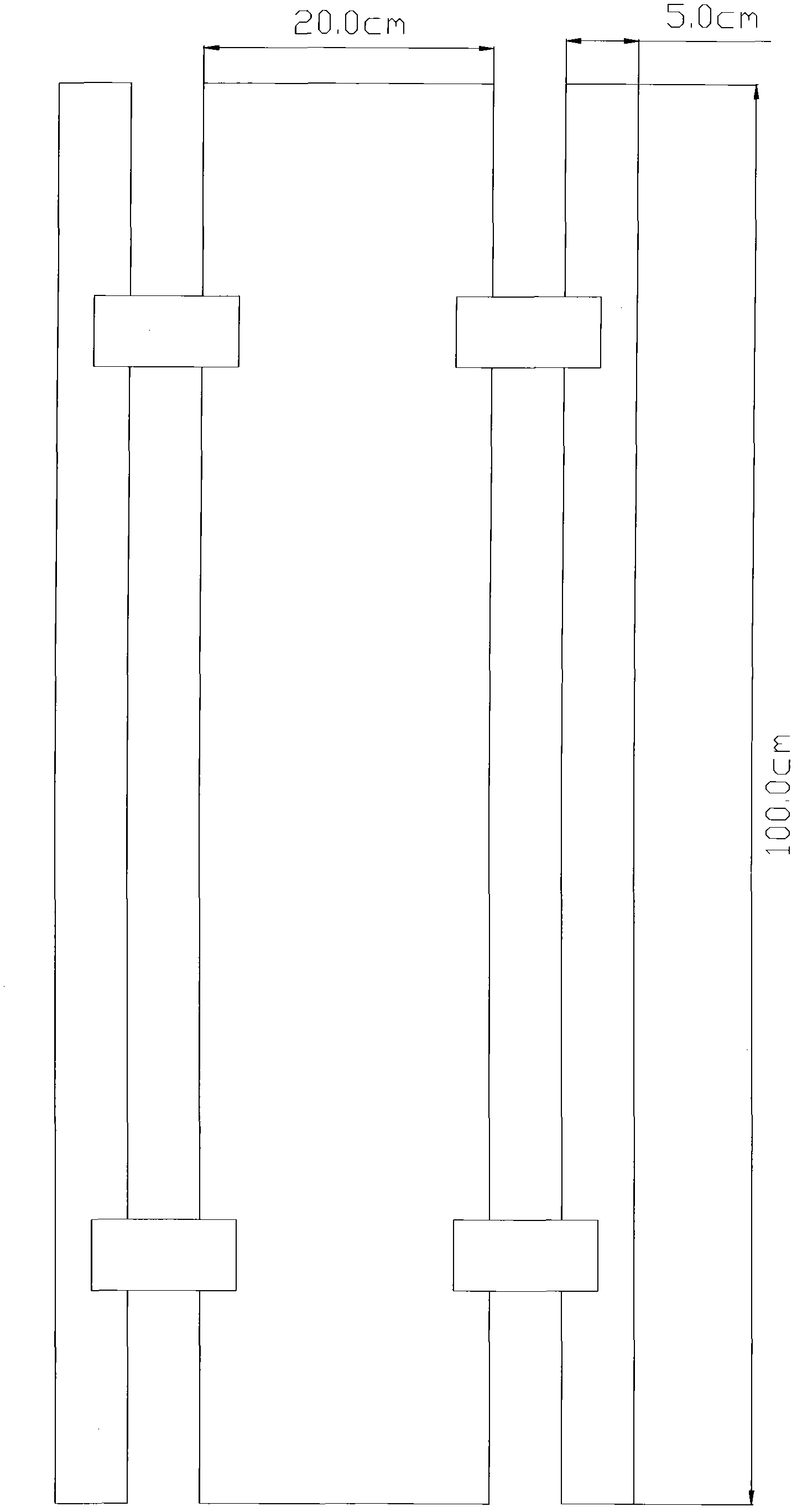

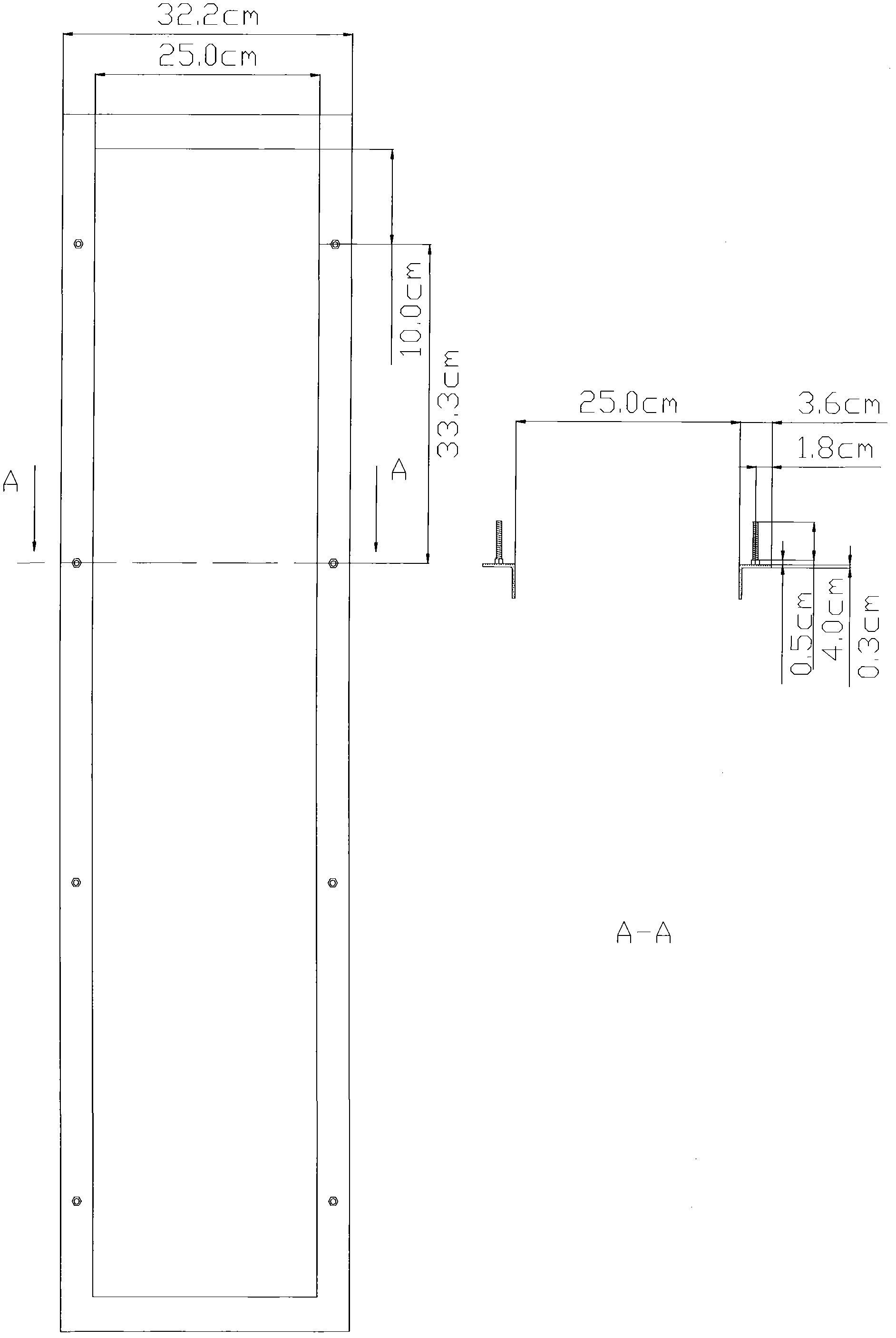

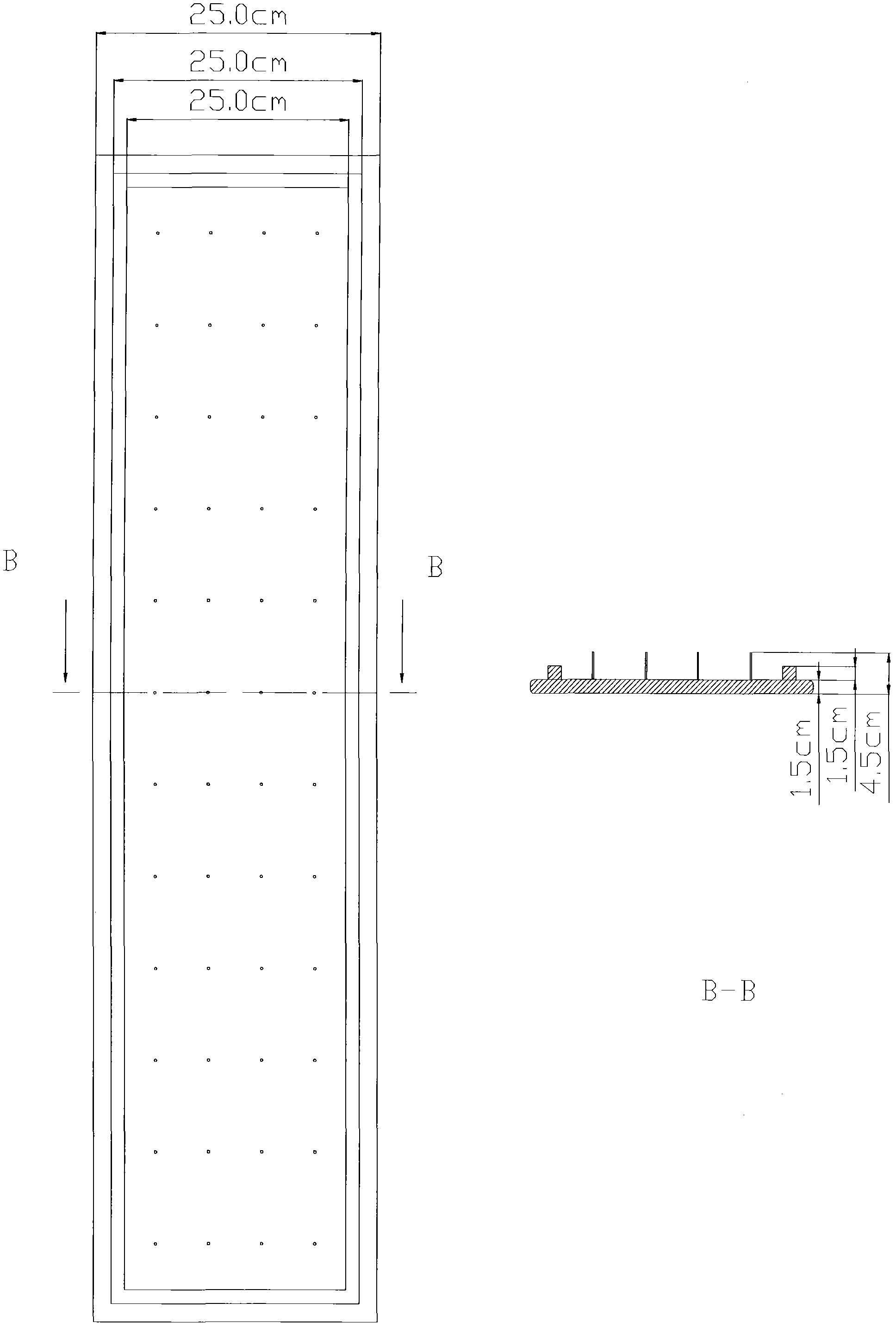

[0009] On the basis of field soil survey, the sampling points of the whole section of soil were selected. Excavate an operation pit with a length of 1.5m, a width of 1.5m, and a depth of 1.3m (the specific size is suitable for the convenience of the collectors). or step surface, used for personnel entry and exit), select the working section, and start the collection of the entire section of soil samples after completing the description and recording of the soil section and the collection of layered soil samples (obtaining relevant information for the establishment of the entire section of the soil section). In the process of collecting the entire section of soil samples, it is necessary to excavate longitudinally in the soil profile according to the size of the soil sampling frame and trim a rectangular soil column outline (the inner side is connected with the profile soil), and excavate along the edge of the outline with a profile knife to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com