Oil separating device

A separation device and cyclone separation device technology, applied in separation methods, dispersed particle separation, mechanical equipment, etc., can solve problems such as multiple installation spaces, and achieve the effects of improving separation capacity, reducing costs, and improving separation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

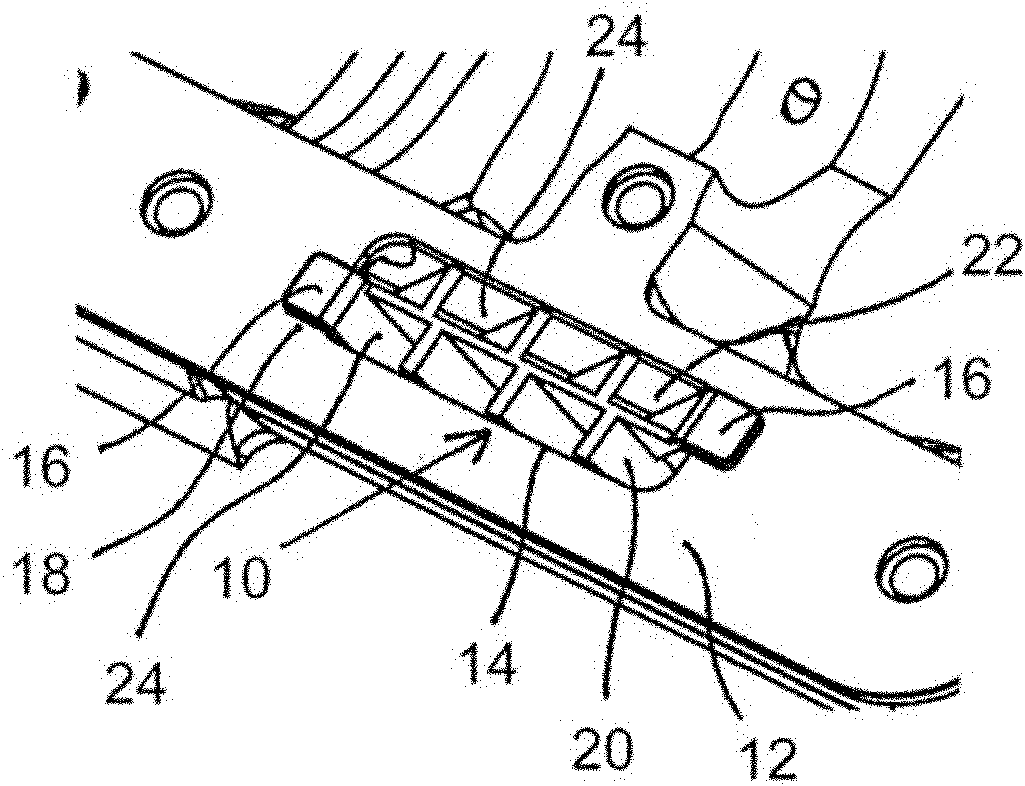

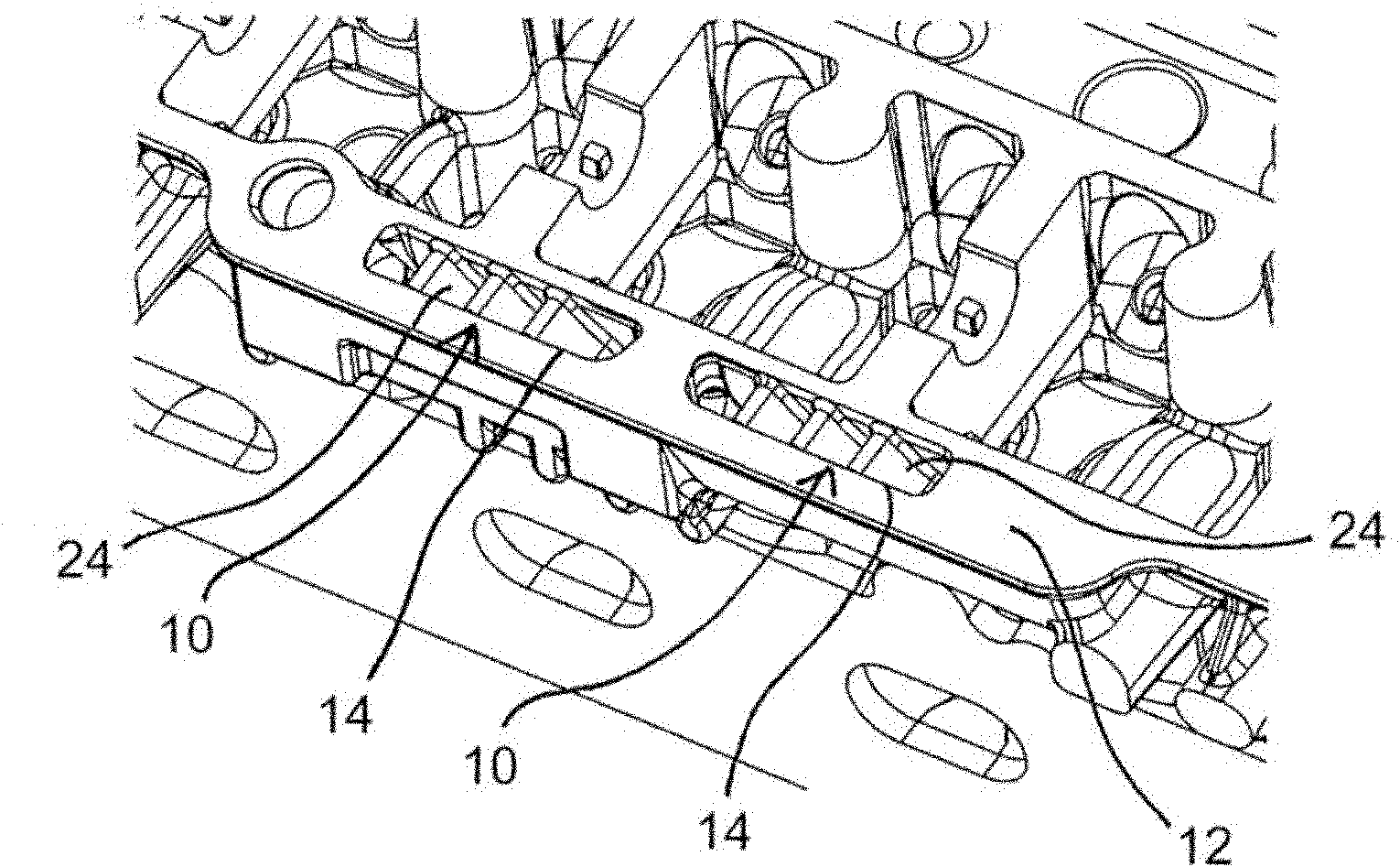

[0024] figure 1 An oil separator device according to the invention for crankcase oil gas of an internal combustion engine is shown schematically, wherein the separating element 10 of the oil separator device is arranged on a cylinder head 12 of the internal combustion engine. In this case, the separating element 10 is arranged in a lifting duct 14 of the cylinder head 12 .

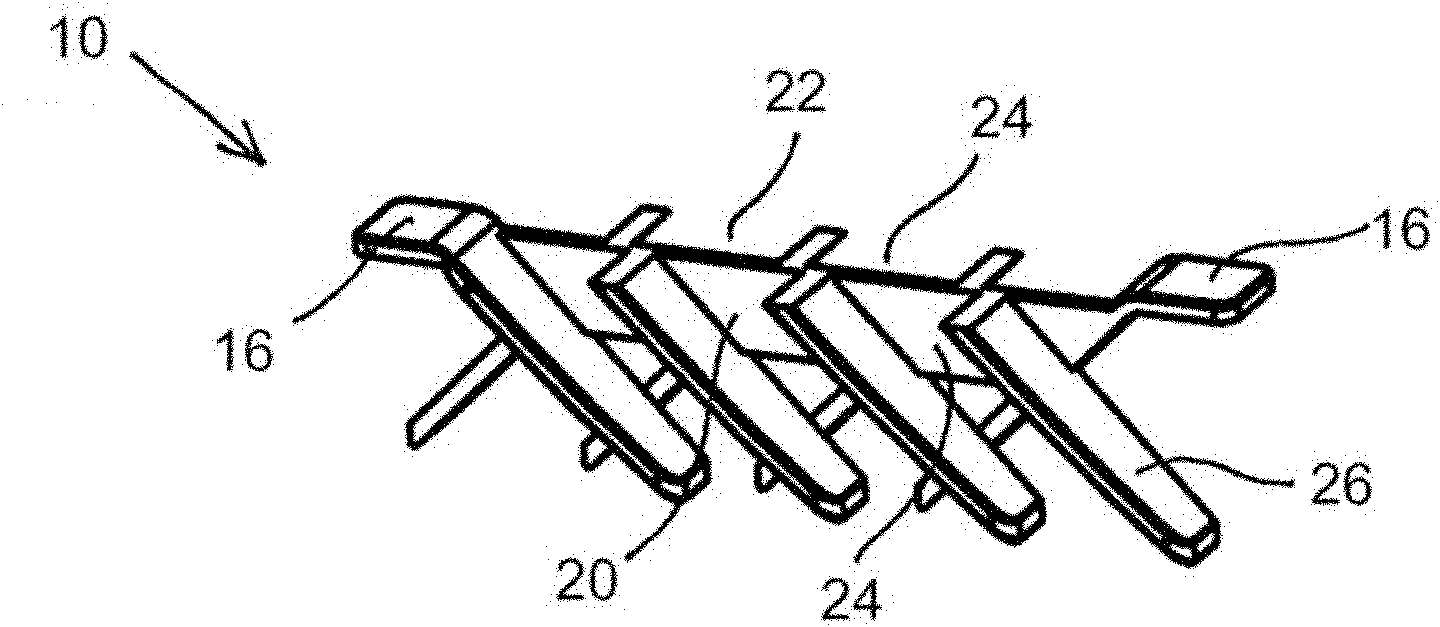

[0025] figure 1 The shown separating element 10 is arranged releasably in a lifting duct 14 of the cylinder head 12 , wherein the separating element 10 is here suspended in the lifting duct 14 . exist figure 2 The separating element 10 shown again separately in FIG. 2 has two hook elements 16 which can be suspended on the edge 18 of the riser pipe 14 by laying the hook elements 16 flat on the edge 18 of the riser pipe 14 . The separating element 10 itself forms a first row 20 and a second row 22 , each of which has four passages through which crankcase oil and gas can flow through the separating elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com