Cathode movement push rod mechanism

A technology of push rod mechanism and cathode movement, which is applied in the electrolysis process, electrolysis components, casting and molding equipment, etc., can solve the problems of difficult to guarantee accuracy, numerous processing procedures, and large floor space, so as to reduce the failure rate, ensure accuracy, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

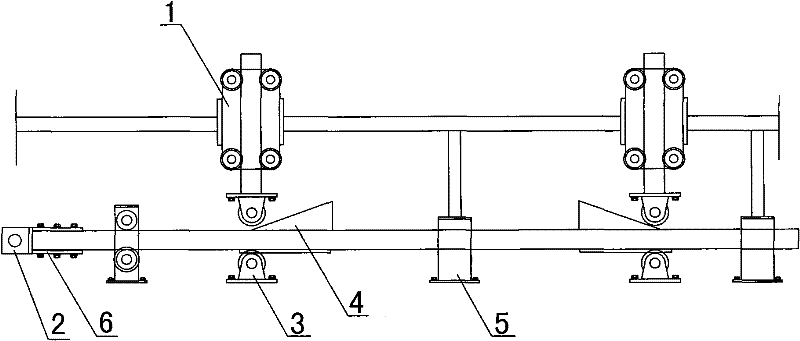

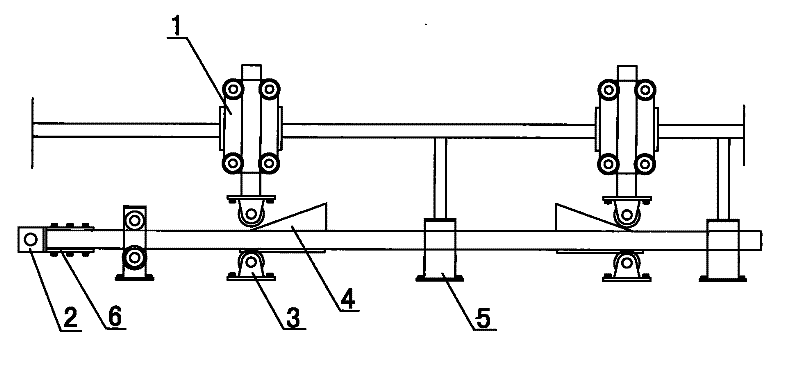

[0010] Such as figure 1 As shown, the cathode moving push rod mechanism of the present invention includes a pulley frame 1, a connecting rod 2, a bearing seat 3, a slanting block 4 and a hollow column support 5, and the connecting rod 2 is installed on a square tube that moves vertically The pulley frame 1 is provided with a slanted block 4 directly below the rollers at the bottom of the pulley frame 1, and a bearing seat 3 is provided on one side of the slanted block 4; a hollow column support 5 is provided between the two slanted blocks 4, and one end of the connecting rod 2 It is fixed on the H-shaped steel frame 6 by bolts to ensure the horizontal accuracy of the connecting rod 2 mechanism, and then the tooling is used to ensure the vertical accuracy of the pulley frame 1 component. When working, the connecting rod 2 can reciprocate in the horizontal direction, and the inclined block 4 can be used to push the square tube in the vertical direction, thereby driving the catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com