Traceless adhesive, and traceless free sticker prepared from same

A technology for pasting glue and supplies, which is applied in the field of pasting glue for preparing seamless and random pasting supplies, which can solve the problems of one-time use, non-movability, small area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

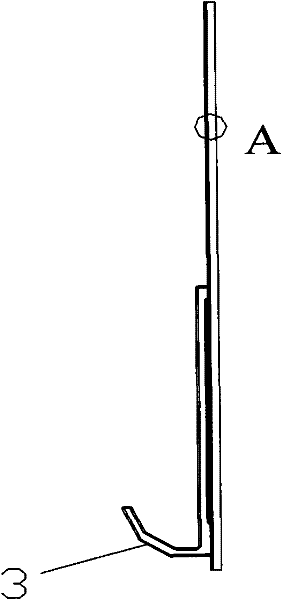

Image

Examples

Embodiment 1

[0022] The weight ratio of various raw materials is as follows:

[0023] Soft elastic material powder (SEBS) (16.95%)

[0024] White oil (mineral oil) (50.85%)

[0025] Titanium dioxide (13.55%)

[0026] Jelly Wax (13.55%)

[0027] White oil tackifier (1.7%)

[0028] Crystal glue (1.7%)

[0029] Nano active calcium carbonate (1.7%)

[0030] At normal temperature, the above materials are mixed; in order to make the various materials disperse or infiltrate each other. Subsequently, the obtained mixture was heated to 160° C. in a reaction kettle, and stirring and dispersion were started for 30 minutes, thereby obtaining a product coating with a uniform composition.

[0031] The adhesive obtained above is sprayed onto the transparent PET film through a spray gun at a temperature of 160°C. Due to the high temperature of the adhesive, the sprayed adhesive can directly and firmly adhere to the PET film to form a bonding layer. A pattern layer can be fixed on the PET film surfa...

Embodiment 2

[0035] The weight ratio of various raw materials is as follows:

[0036] Soft elastic material powder (SEBS) (16%)

[0037] White oil (mineral oil) (50%)

[0038] Titanium dioxide (16%)

[0039] Jelly Wax (16%)

[0040] Nano Active Calcium Carbonate (2%)

[0041] At normal temperature, the above materials are mixed; in order to make the various materials disperse or infiltrate each other. Subsequently, the obtained mixture was heated to 150° C. in a reaction kettle, and stirring and dispersion were started for 60 minutes, so as to obtain a product coating with a uniform composition.

[0042] The adhesive obtained above is sprayed onto the transparent PET film through a spray gun at a temperature of 160°C. Due to the high temperature of the adhesive, the sprayed adhesive can directly and firmly adhere to the PET film to form a bonding layer. A pattern layer can be fixed on the PET film surface of the bonding layer by means of glue sticking or the like. The glued surface o...

Embodiment 3

[0046] The weight ratio of various raw materials is as follows:

[0047] Soft elastic material powder (SEBS) (19%)

[0048] White oil (mineral oil) (60%)

[0049] Titanium dioxide (19%)

[0050] Nano Active Calcium Carbonate (2%)

[0051] At normal temperature, the above materials are mixed; in order to make the various materials disperse or infiltrate each other. Subsequently, the obtained mixture was heated to 160° C. in a reaction kettle, and stirring and dispersion were started for 40 minutes, so as to obtain a product coating with a uniform composition.

[0052] The adhesive obtained above is sprayed onto the transparent PET film through a spray gun at a temperature of 160°C. Due to the high temperature of the adhesive, the sprayed adhesive can directly and firmly adhere to the PET film to form a bonding layer. A pattern layer can be fixed on the PET film surface of the bonding layer by means of glue sticking or the like. The glued surface of the pasting layer can abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com