Automatic sand pouring machine for hub

A sand pouring machine and automatic technology, applied in the field of wheel hub manufacturing, can solve problems such as high labor intensity, undiscovered technical literature, and harsh environment, and achieve high production efficiency, good environmental protection effect, and scientific and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

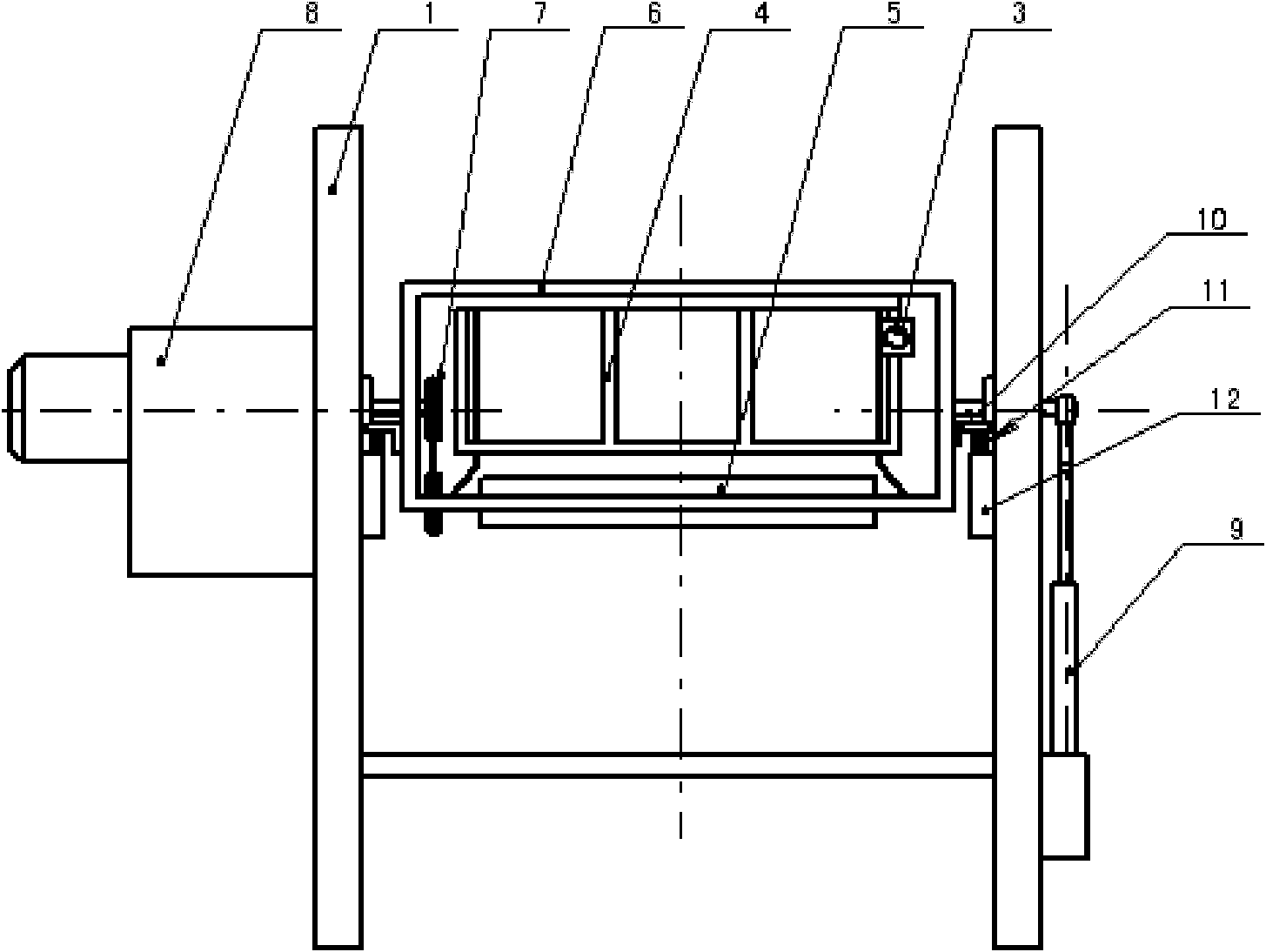

[0016] An automatic sand dumping machine for wheel hubs, which is composed of support plates 1 on both sides, wheel baskets 6, drive rollers 5, drive motors 8 and cylinders 9, and the wheel baskets are fixed horizontally through shafts between the support plates on both sides. The wheel baskets are Frame-type structure, the drive roller row is installed horizontally on the bottom of the wheel basket, and the drive roller row can place and run the wheel hub; a baffle plate 4 is hinged at the front of the wheel basket through the shaft seat 2, and the baffle plate passes through the solid A baffle cylinder frame 3 mounted on one side of the wheel basket is driven to realize opening or closing; a sprocke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com