Device and method for controlling camber of board blank of sizing press (SP)

A control method and sickle bending technology, applied in the direction of roll speed control, length measuring device, metal rolling, etc., can solve problems affecting the smooth and stable rolling process, deviation of equipment function accuracy, poor centering of slabs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] like image 3 As shown, the large side pressure fixed width machine of the present invention includes a guide plate assembly 11, an oil cylinder 12, an oil circuit 14, a reversing valve 13, and a synchronous speed compensation control system.

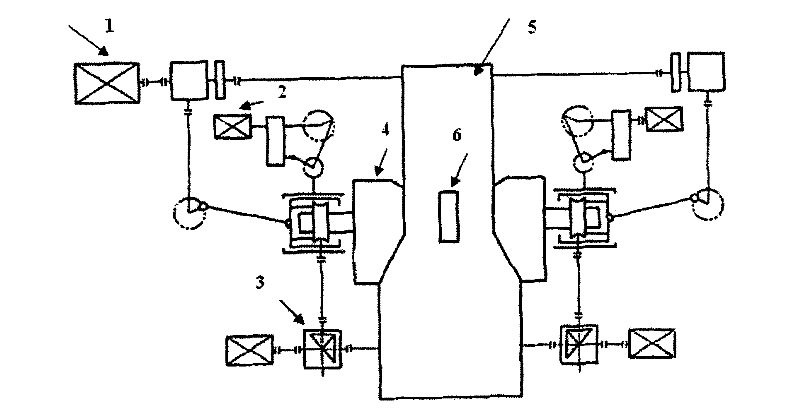

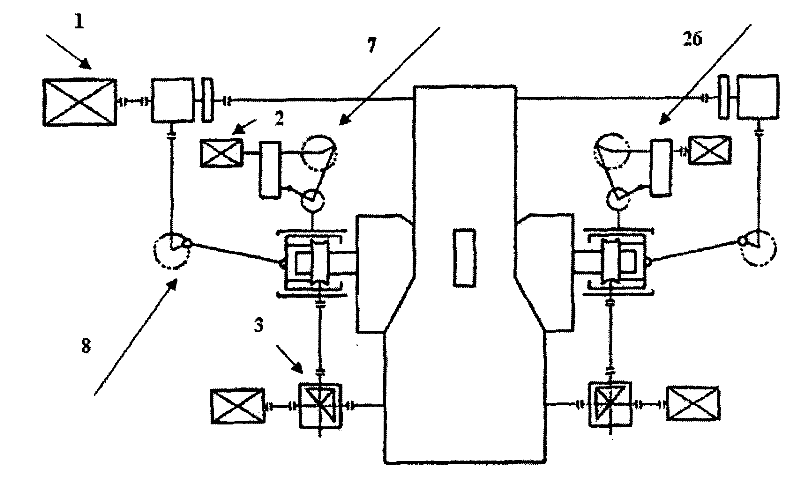

[0122] like Figure 7 As shown, the synchronous speed control system includes a main motor 1 , two synchronous motors 2 , two module opening adjustment mechanisms 3 , two synchronous cranks 7 , a main crank 8 , and two speed adjustment systems 26 .

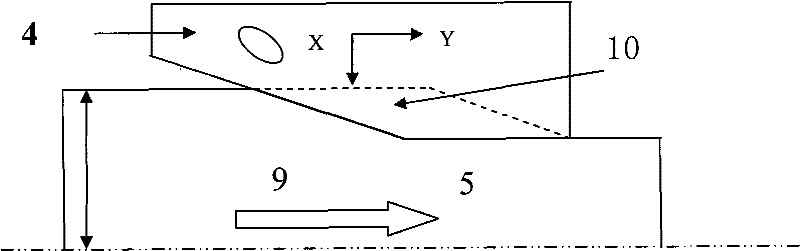

[0123] like Figure 4 As shown, the two synchronous cranks are driven by their respective synchronous motors, and they adjust the rotation speed according to the angle of rotation of the main crank and the direction of rotation 22 to achieve synchronization. In order to facilitate the control, several special positions (angles) on the motion tracks of the main crank and the synchronous crank are artificially defined. The relationship between the positioning and angle of the main c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com