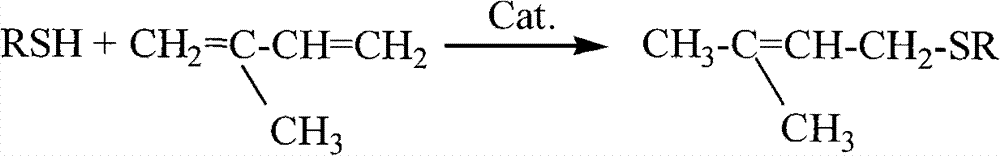

Mercaptan etherification catalyst

A catalyst and etherification technology, applied in the direction of physical/chemical process catalyst, catalyst activation/preparation, sulfide preparation, etc., can solve the problems of a large amount of alkali slag, environmental pollution, etc., and achieve high desulfurization efficiency, low price, good choice The effect of hydrogenation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

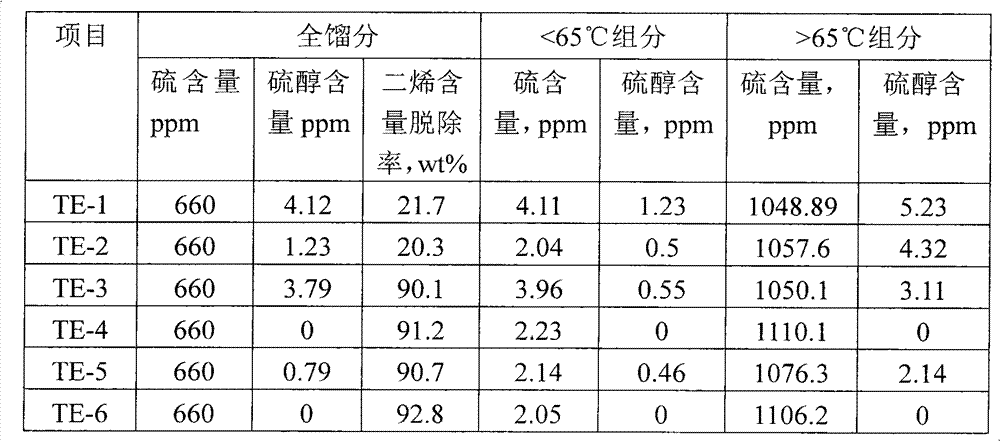

Embodiment 1

[0030] This example prepares a kind of Ni / Al by impregnation loading method 2 o 3 catalyst. Weigh 100g pseudo-boehmite powder (Al 2 o 3 Dry basis content is 70wt%), adding accounted for Al 2 o 3 Dry base 5wt% Tianjing powder additive 3.5g, mass concentration 5wt% nitric acid aqueous solution 80g, mix and roll and mix into plastic powder, prepare the cylindrical strip that diameter is 1.5mm with extrusion machine, dry at 100 ℃ 8h, calcination at 500°C for 2h, Al 2 o 3 carrier. Loading of active components: Take 13.68g of nickel nitrate according to the amount of NiO content on the final catalyst accounting for 15wt% of the carrier, add 14.87g of deionized water to make a solution, then impregnate 20g of the above carrier for 8h, dry at 100°C for 10h, 500°C Lower roasting for 2h to prepare NiO / Al 2 o 3 catalyst.

[0031] Put the catalyst above into a fixed-bed reactor, and reduce it at 450°C for 4 hours at a pressure of 0.2MPa and a hydrogen-oil volume ratio of 300:1;...

Embodiment 2

[0033] This example adopts example 1 method to make Al 2 o 3 Carrier, the loading of active components accounts for 10wt% of the total weight of the catalyst according to the NiO content on the final catalyst, MoO 3 The content accounts for 3wt% of the total weight of the catalyst. Quantitatively weigh 8.92g of nickel nitrate and 0.85g of ammonium molybdate, add 16.69g of water to prepare a solution, then impregnate with 20g of the above carrier for 8h, dry at 100°C for 10h, and roast at 500°C 2h, prepared NiO-MoO 3 / Al 2 o 3 catalyst.

[0034] Ni-Mo-S / Al is prepared by reduction and vulcanization method in Example 1 2 o 3 Catalyst, abbreviated as TE-2 catalyst.

Embodiment 3

[0036] To the Al prepared in example 1 2 o 3 The carrier is modified by using MgO in a loading mode, and the magnesium nitrate of 0.93g is weighed according to the amount that the MgO content accounts for 1wt% of the carrier weight, and 19.8g of deionized water is added to form a solution, and then mixed with 20g of Al 2 o 3 The carrier was impregnated for 8 hours, dried at 100°C for 10 hours, and calcined at 500°C for 2 hours to prepare MgO-Al 2 o 3 Composite modified carrier.

[0037] Using the same raw materials and methods as impregnated, reduced and vulcanized in Example 1 and Example 2, Ni-S / MgO-Al was prepared 2 o 3 and Ni-Mo-S / MgO-Al 2 o 3 Catalysts are abbreviated as TE-3 and TE-4 catalysts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com