Tomato seed treatment method

A seed treatment and seed technology, which is applied in the field of tomato seed coating and initiation treatment, can solve the problem that the seed pelletizing technology cannot meet production requirements, and achieve the effects of facilitating manual and mechanized sowing, overcoming the long time and volume increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

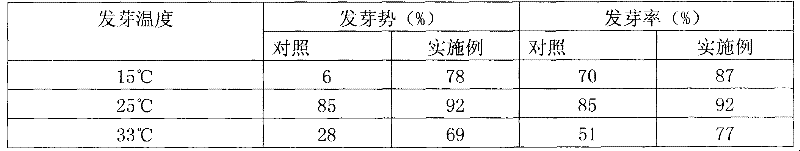

Examples

Embodiment 1

[0014] Thoroughly mix tomato seeds (variety A) with vermiculite and water in a weight ratio of 2:4:3, place in a closed container, and place at 10° C. for 10 days. After initiating, the tomato seeds are separated from the vermiculite with a sieve, and 500 grams of tomato seeds are poured into the rotary coating machine with 4 grades of speed, while adding talcum powder, bentonite mixed powder (weight ratio is 4: 1), While adding 0.5% carboxymethyl cellulose aqueous solution, repeat the operation in this way, accumulatively add 1000 grams of mixed powder and 100 ml of carboxymethyl cellulose aqueous solution. Store in airtight water.

Embodiment 2

[0016] Thoroughly mix tomato seeds (variety B) with vermiculite and water at a weight ratio of 1:2:2, place in a closed container, and place at 15° C. for 7 days. After initiating, tomato seeds are separated from vermiculite with a sieve, and 1000 grams of tomato seeds are poured into the rotary coating machine with 4 grades of speed, while adding talcum powder, bentonite mixed powder (weight ratio is 3: 1), While adding 2% polyvinylpyrrolidone aqueous solution, repeat the operation, accumulatively add 1,500 grams of mixed powder, 200 ml of carboxymethyl cellulose aqueous solution, take out the seeds after coating, and dry them in a 35°C drying oven to a safe water content. Store airtight.

Embodiment 3

[0018] Thoroughly mix tomato seeds (variety C) with vermiculite and water in a weight ratio of 2:3:2, place in a closed container, and place at 20° C. for 5 days. After initiating, the tomato seeds are separated from the vermiculite with a sieve, and 250 grams of tomato seeds are poured into the rotary coating machine with 4 grades of speed, while adding talcum powder, bentonite mixed powder (weight ratio is 5: 1), While adding 4% polyvinyl alcohol aqueous solution, repeat the operation in this way, accumulatively add 500 grams of mixed powder, 50 ml of carboxymethyl cellulose aqueous solution, take out the seeds after coating and place them in a drying oven at 35°C to dry to a safe water content. Store airtight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com