Preset cavity type SOI (silicon on insulator) substrate film bulk acoustic wave filter and manufacturing method thereof

A thin-film bulk acoustic wave and manufacturing method technology, applied to electrical components, impedance networks, etc., can solve the problems of increasing the process, the impact of structural reliability, and the long time required for release, and achieve the effect of simple process and easy integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

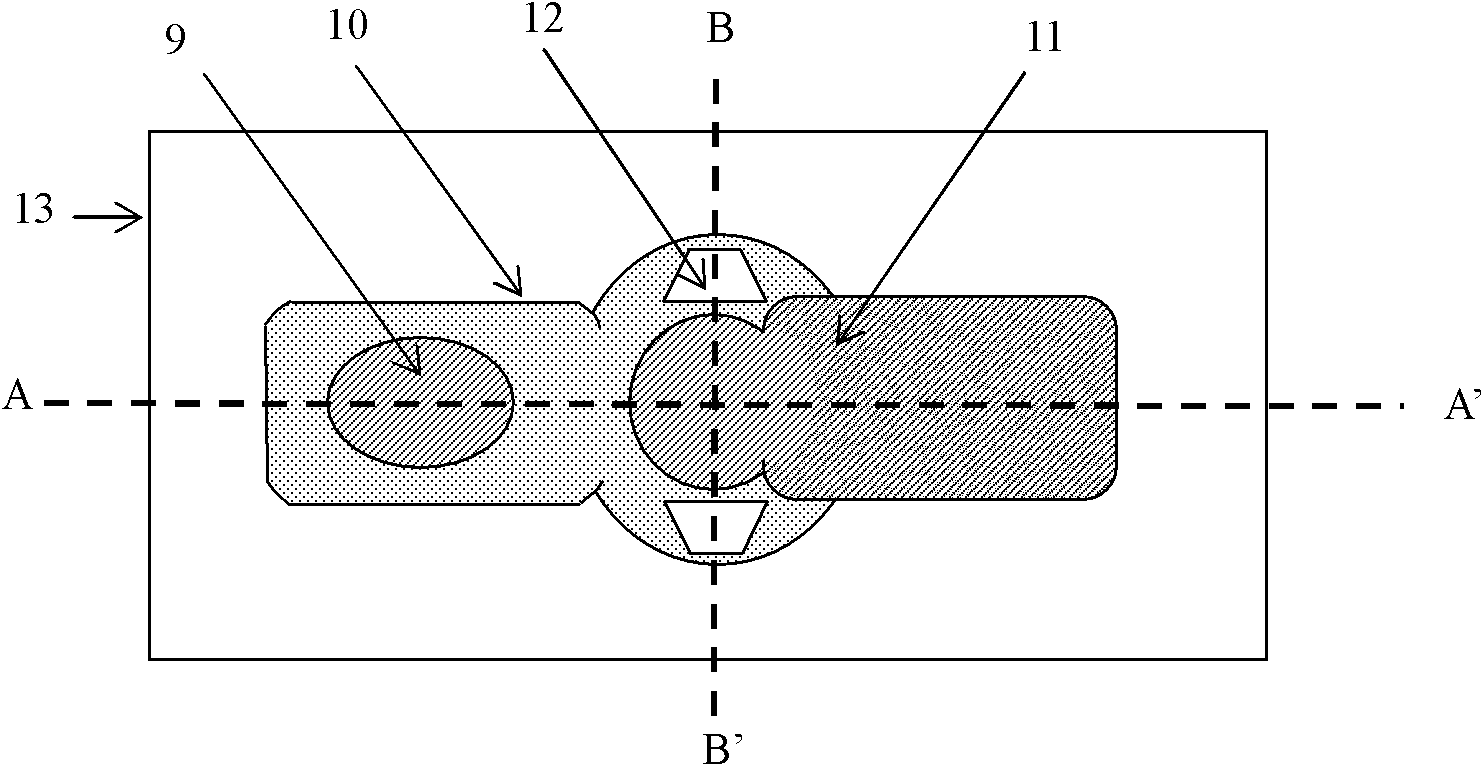

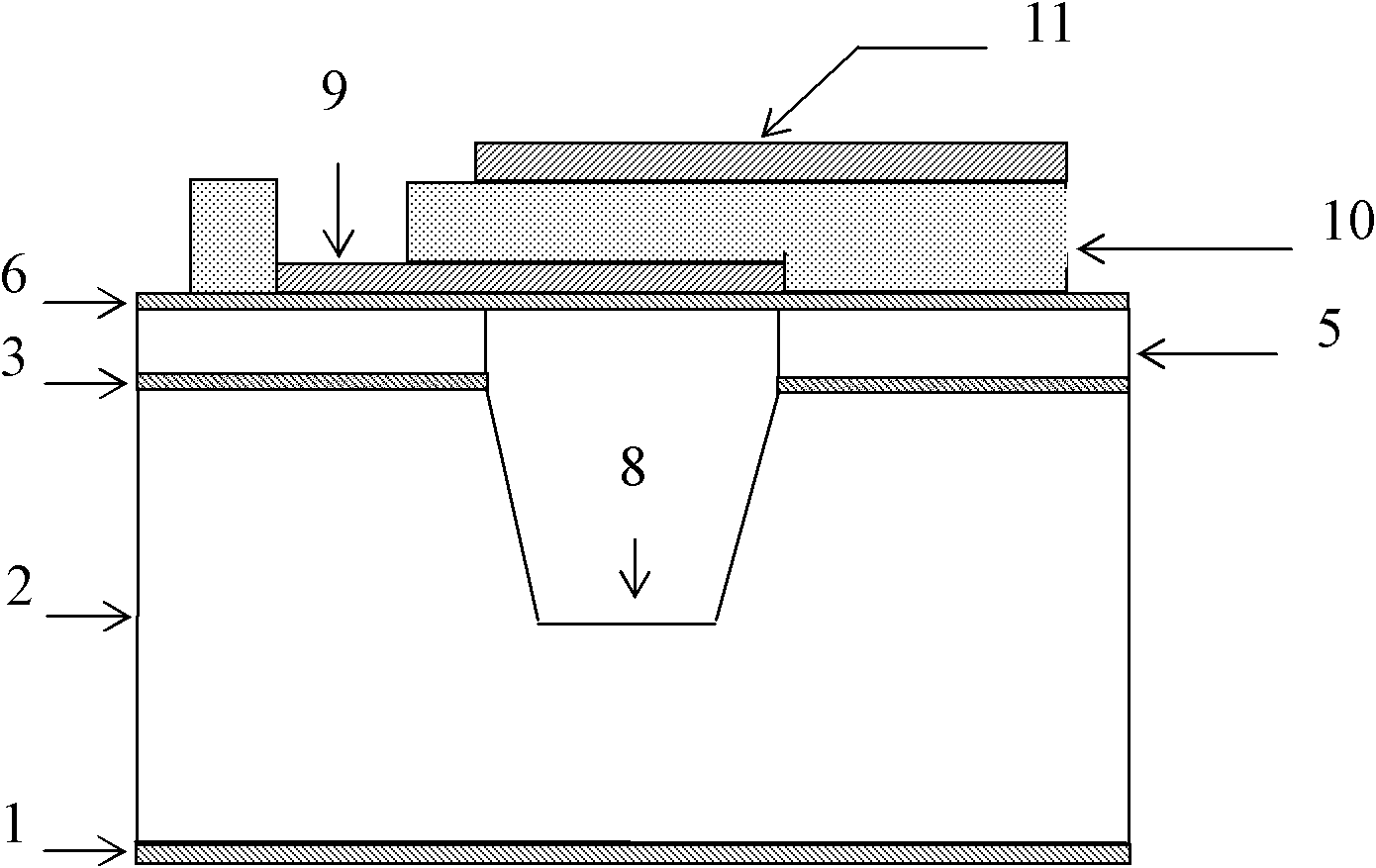

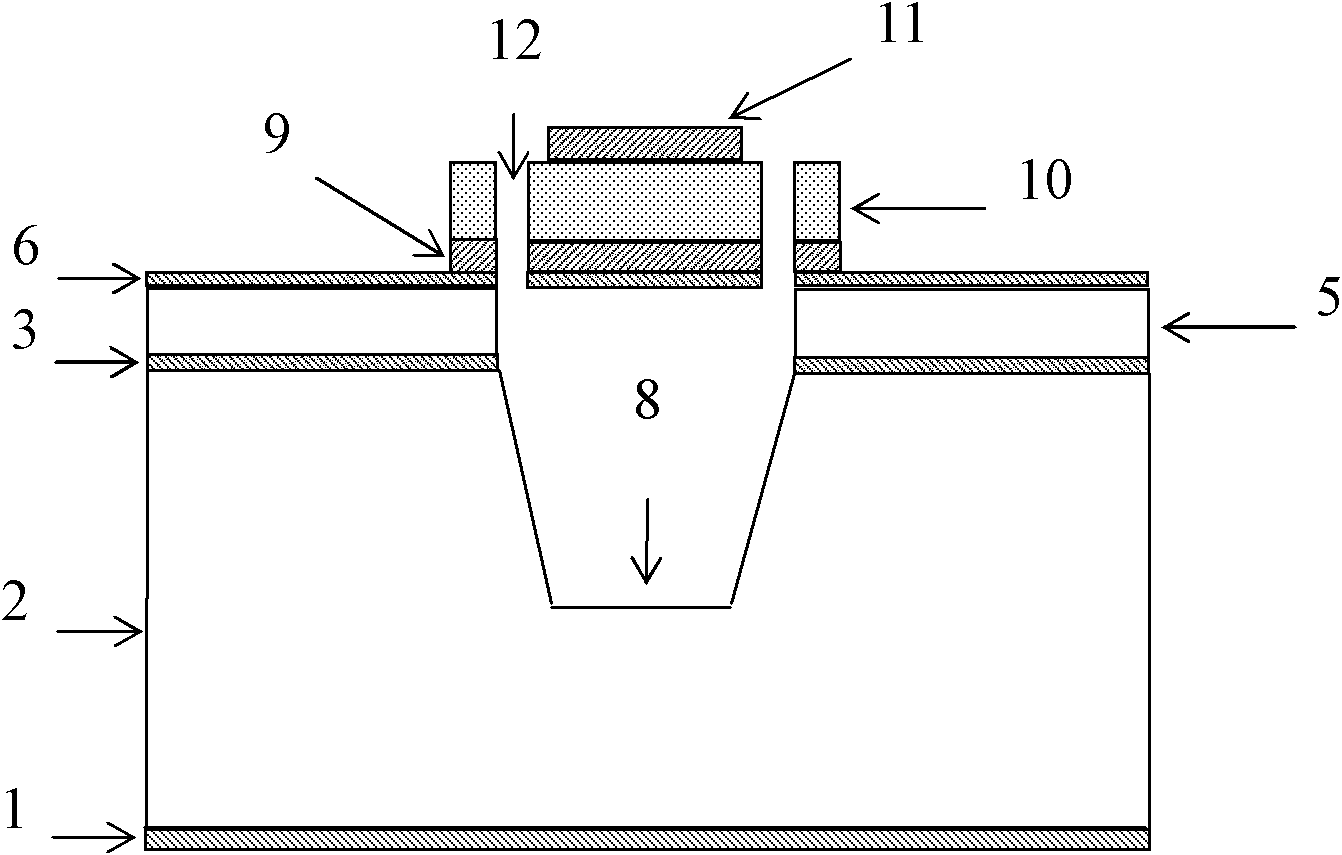

[0053] figure 1 It is the top plan view of the FBAR unit of the present invention, figure 2 for the invention figure 1 Middle A-A' profile, image 3 for the invention figure 1 In the sectional view of BB', as shown in the figure, the preset cavity-type SOI substrate thin-film bulk acoustic wave filter provided by the present invention includes a plurality of thin-film bulk acoustic wave resonators connected by electrical cascading, each thin-film bulk acoustic wave filter The acoustic wave resonator includes a preset cavity 8 type SOI substrate 13 and a transducer arranged on the SOI substrate 13, the transducer includes a bottom electrode 9, a top electrode 11 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com