Laser direct-writing device

A technology of laser direct writing and laser interferometer, which is used in photoplate-making process exposure devices, laser welding equipment, microlithography exposure equipment, etc. Micro-nano graphics and other problems, to achieve the effect of high-precision and rapid writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the examples.

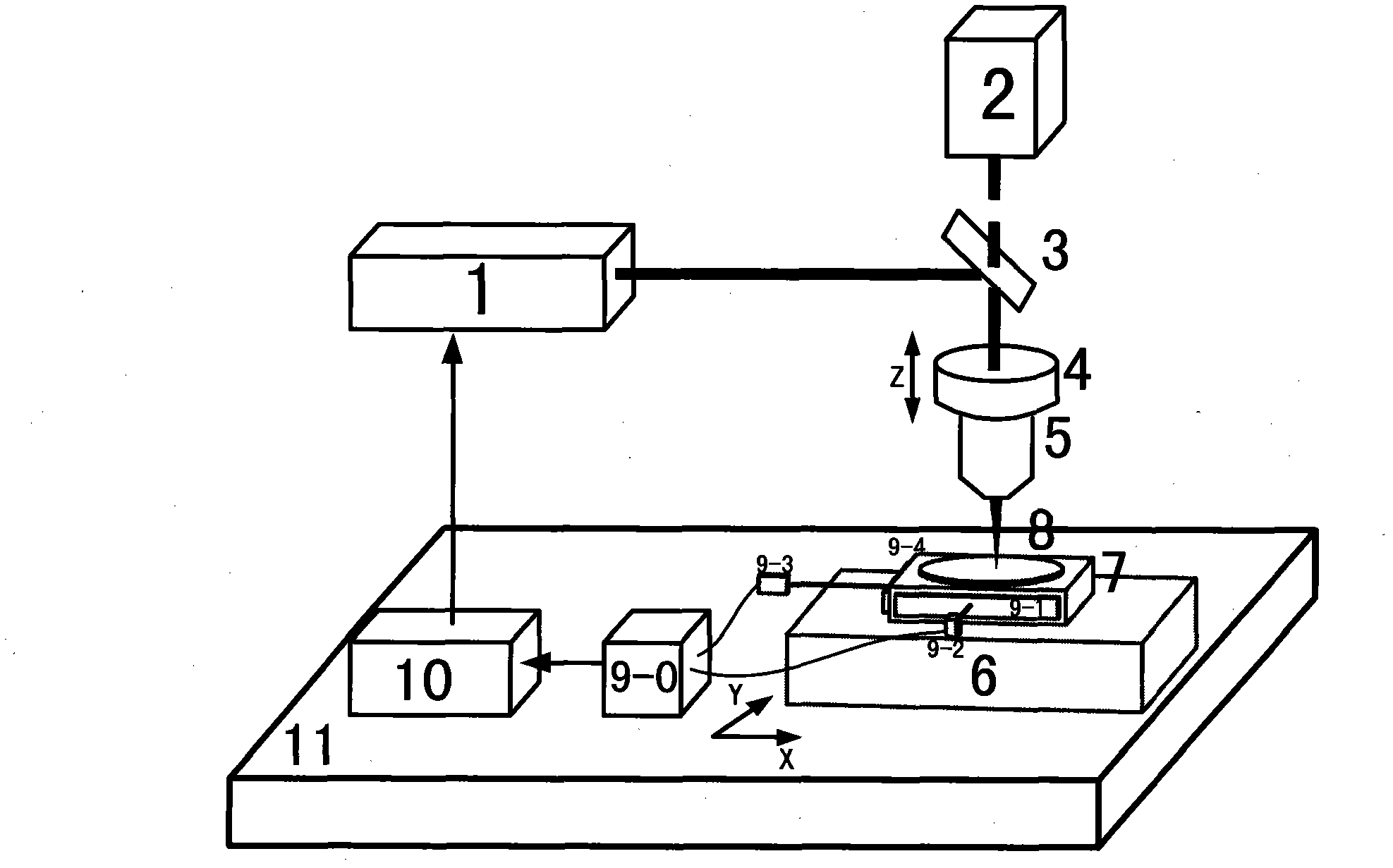

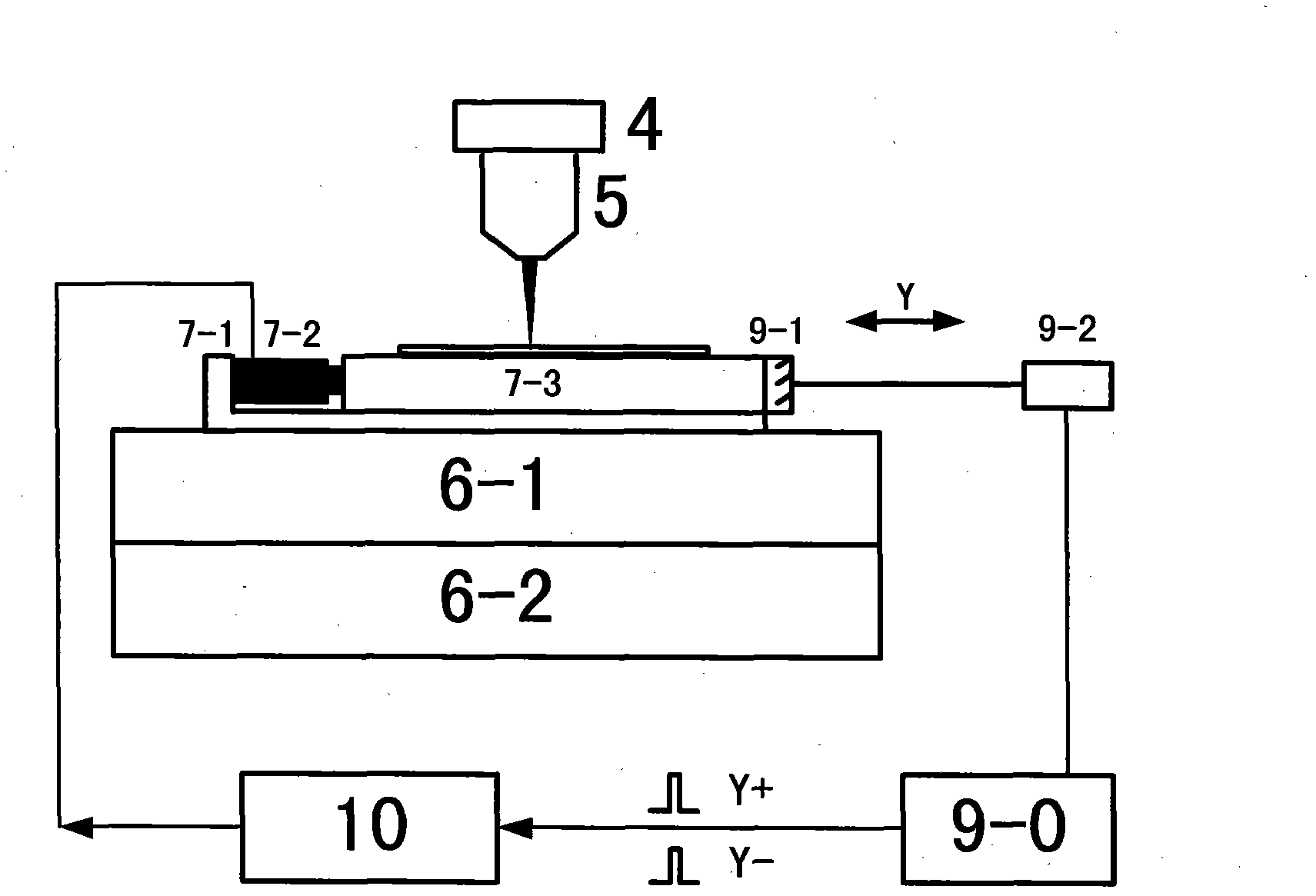

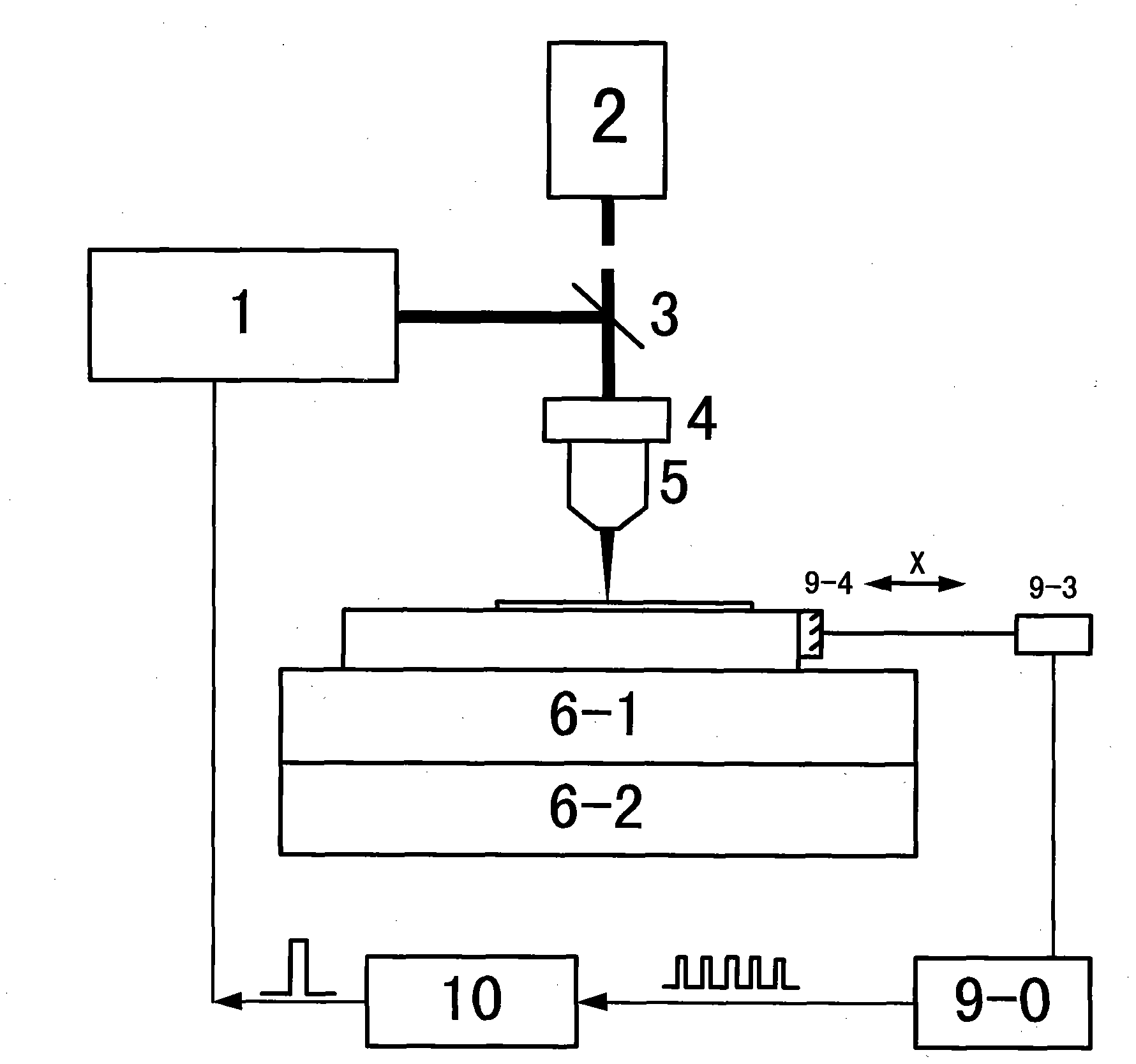

[0021] Such as figure 1 , The laser direct writing device of the present invention includes a writing light source 1, a defocus detection module 2, a spectral beam splitter 3, a focusing PZT4, an objective lens 5, a two-dimensional XY motor platform 6, a Y-axis correction platform 7, a sample to be engraved 8, a laser Interferometer 9, master controller 10 and anti-vibration table 11, the positional relationship of above-mentioned parts is as follows:

[0022] The two-dimensional XY motor platform 6 and the general controller 10 are set on the anti-vibration table 11, the Y-axis correction platform 7 is fixed on the two-dimensional XY motor platform 6, and the samples to be engraved 8 are placed On the Y-axis correction platform 7, the writing light source 1 and the defocus detection module 2 are respectively located on both sides of the spectral beam splitter 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com