Polarization method for ferroelectric crystal material

A ferroelectric crystal, repolarization technology, applied in nonlinear optics, instruments, optics, etc., to achieve easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

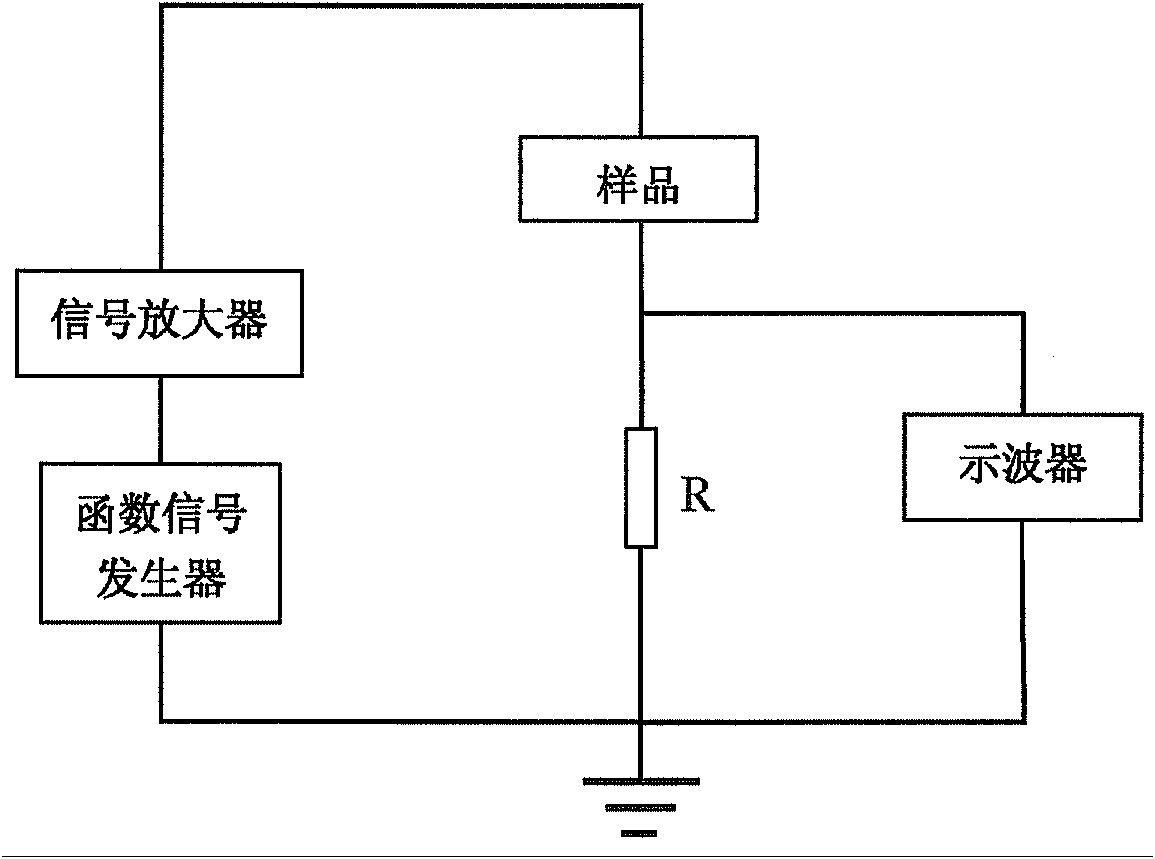

Method used

Image

Examples

Embodiment 1

[0036] In this example, a lithium niobate periodically polarized crystal with a period of 4.2 μm is obtained by two-step polarization, which is suitable for frequency-doubling output of light waves with a wavelength of 850 nm.

[0037] 1. First obtain a periodically polarized crystal with a period of 8.4 μm and a polarization duty ratio of 25%. As attached image 3 As shown in the first step, the ferroelectric domain reversal after polarization is shown in Figure 4 Shown.

[0038] 2. Perform the second step of polarization on the basis of 1, as attached image 3 In the second step, the ferroelectric domain reversal after polarization is shown in Figure 5 Shown.

[0039] 3. In this example, the width and length of the metal electrode are determined according to the law of domain growth and experimental requirements.

Embodiment 2

[0041] The three-step or multi-step polarization method in this example. Only need to change the polarization step into three or more steps. If it is three or more steps, the grating metal electrode required for polarization is composed of three or more parts. Each step of the polarization process connects the high voltage pulse to the grating electrode. Part, until all the polarization steps have been implemented.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com