Warp Knitting Filament Warping Machine Tension Balance Device

A tension balance device and warping machine technology, which is applied in the field of warping machines, can solve problems such as small tension control adjustment range, uneven yarn tension, and inaccurate tension control, and achieve a large tension control range and high tension control accuracy , simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Describe the present invention in detail below in conjunction with accompanying drawing:

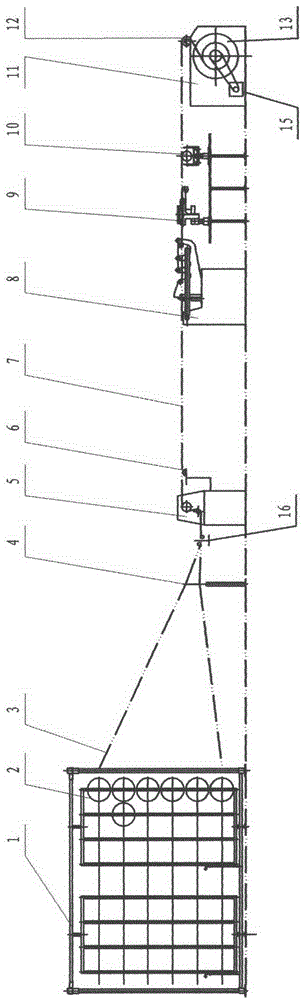

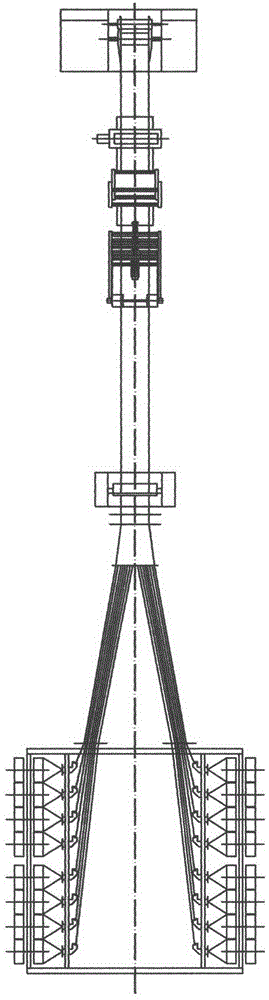

[0015] Such as Figure 1-4 Shown, this warp-knitting filament warping machine tension balance device, in prior art warp-knitting filament warping machine electrical control system, pneumatic control system, creel 1, silk collecting plate 4, inline reed 16, On the basis of the structure of the hairiness detector 6, the yarn storage device 8, the tension detection device 9, the oiling device 10, and the machine head 11, two motors are arranged in front of the straight reed 16 and behind the hairiness detector 6 to drive the upper The tension balance device 5 of the tension roller 26 and the lower tension roller 24 controls the tension that the sheet yarn 7 is wound into the pan head 13 .

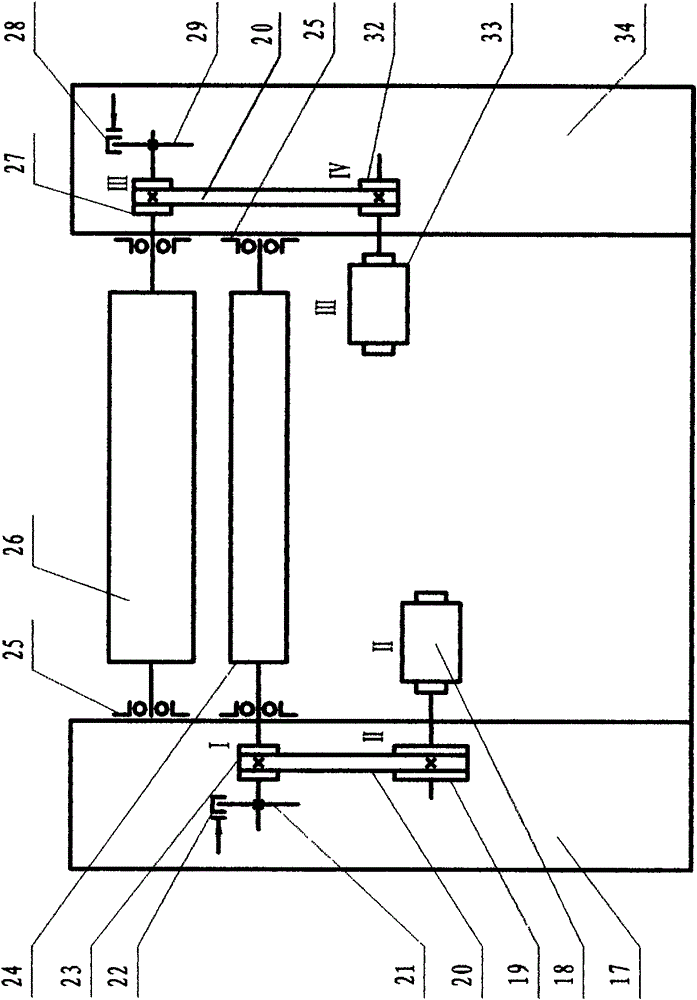

[0016] Such as Figure 3-4 As shown, in the tension balance device 5, the upper tension roller 26 and the lower tension roller 24 are arranged in parallel, and one end of the upper tension rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com