Total-flooding jet polishing device and method

A polishing device and fully submerged technology, which is applied in the direction of abrasive jet machine tools, abrasives, metal processing equipment, etc., to achieve the effects of reducing the difficulty of system polishing control, simple structure, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

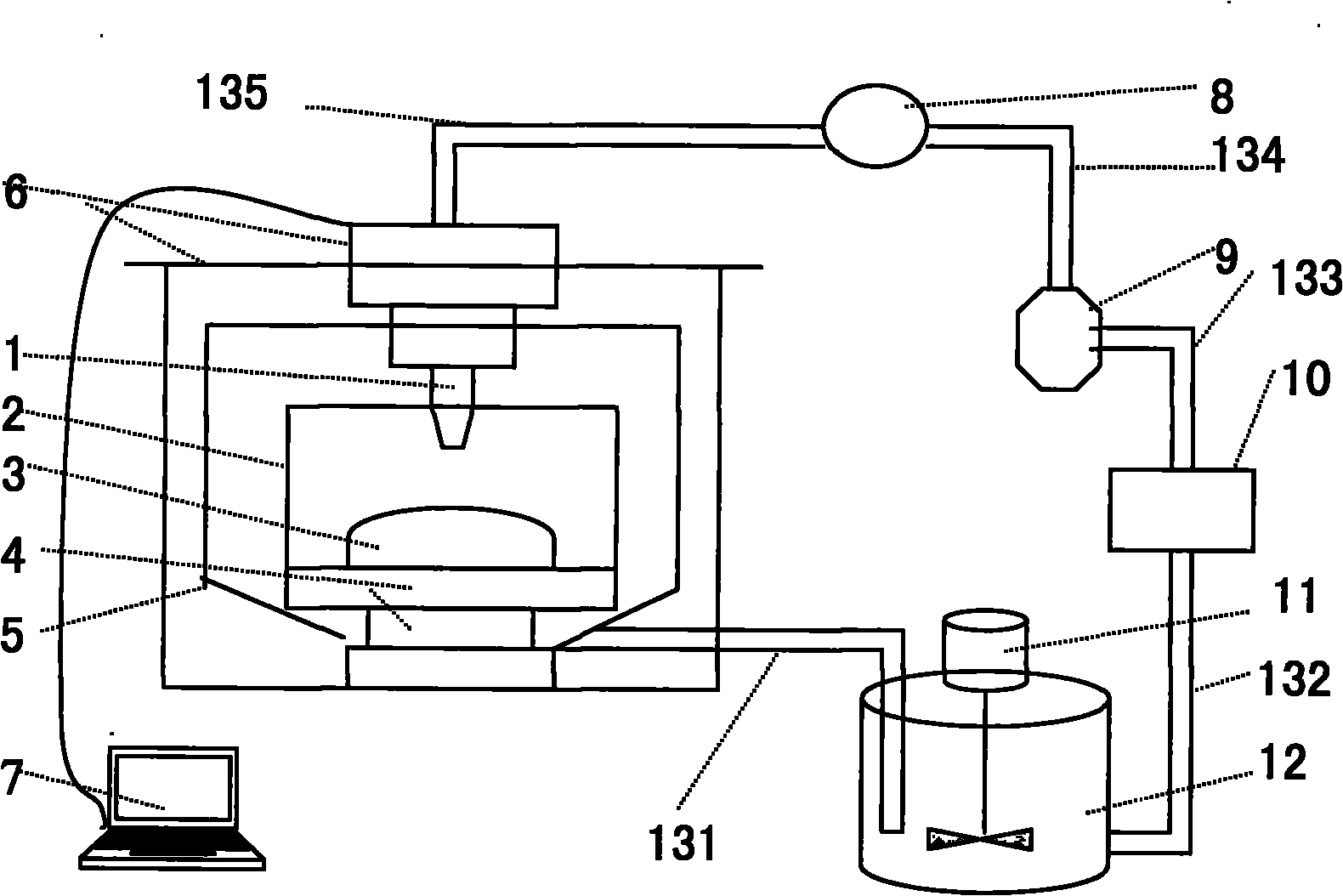

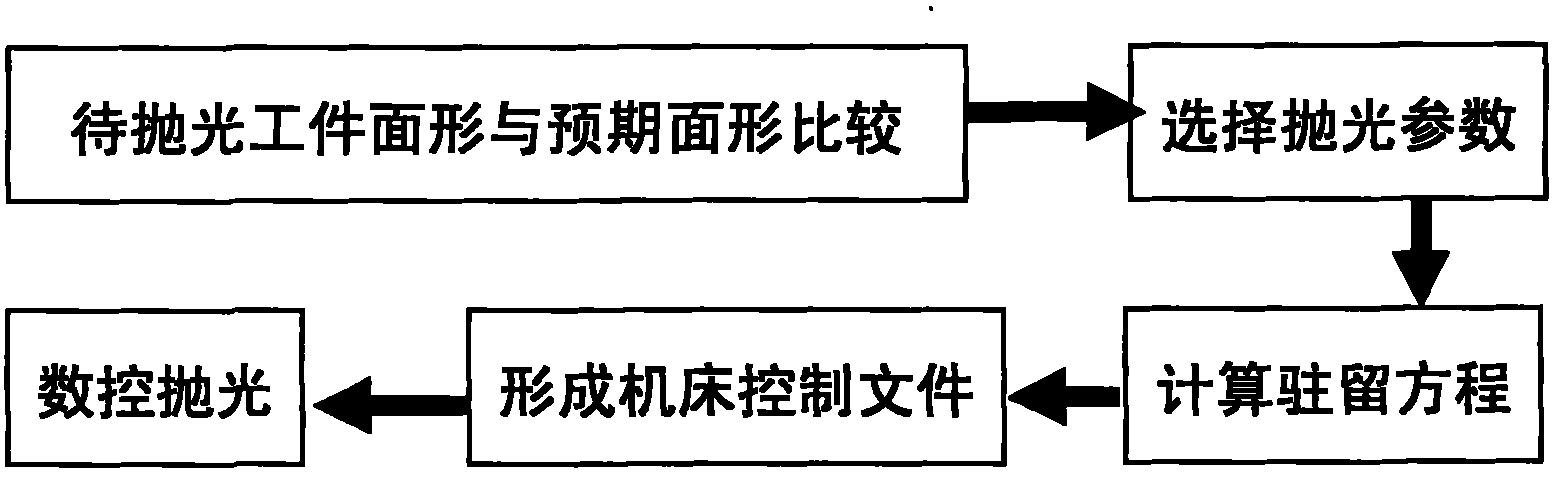

[0022] Example 1: Combining figure 1 The fully submerged jet device system describes this embodiment. This embodiment includes a nozzle 1, a polishing liquid container 2, a workpiece to be polished 3, a workpiece clamping 4, a polishing liquid recovery tank 5, a numerically controlled polishing machine tool 6, a numerically controlled computer 7, and a pressure gauge 8 , a pressure regulating valve 9, a booster pump 10, a polishing liquid agitator 11, a polishing liquid recovery container 12 and several liquid pipelines 131 to 135. The polishing liquid recovery tank 5 is fixed on the workpiece table of the CNC polishing machine tool 6; the polishing liquid container 2 is fixed on the polishing liquid recovery tank 5; One end of the nozzle 1 is fixed in the polishing head of the CNC polishing machine 6, and the other end of the nozzle 1 is connected to one end of the fifth liquid pipeline 135; the two ports of the pressure gauge 8 are respectively fixed with the first The othe...

Embodiment 2

[0024] Embodiment 2: Combination figure 1To illustrate this embodiment, the CNC machine tool and the CNC system of this embodiment use the CCOS800mm polishing machine tool and CNC system developed by the Institute of Optoelectronics, Chinese Academy of Sciences. The nozzle 1 is a cylindrical nozzle, and the nozzle 1 is a cylindrical nozzle of the LECHLER brand. On the polishing head of machine tool 6, under the instruction of numerical control computer 7, nozzle 1 can realize the motion of X, Y, Z three directions, and the booster pump 10 of this embodiment can select the VA10 model diaphragm pump of German Verder Company for use, this The polishing liquid recovery part of the embodiment includes a polishing liquid recovery container 12 and a polishing liquid agitator 11, and the polishing liquid agitator 11 can be realized by using a conventional motor equipped with stirring blades. The polishing liquid agitator 11 is located in the polishing liquid recovery container 12 for ...

Embodiment 3

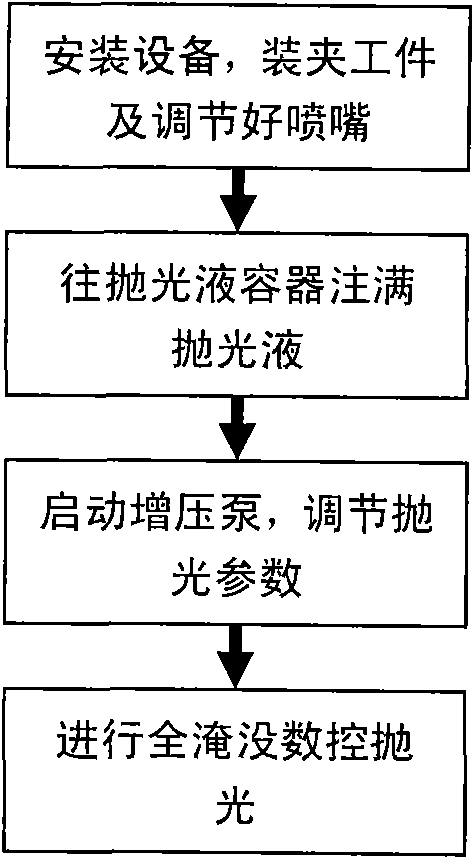

[0025] Example Three: Combining figure 1 and image 3 Describe this embodiment, this embodiment is realized through the following steps:

[0026] Step S1: After fixing each component according to the specific embodiment 1, the workpiece 3 to be polished is clamped in the polishing liquid container 2 through the workpiece clamping 4, and the workpiece clamping 4 is adjusted so that the topmost distance of the workpiece 3 to be polished is away from the polishing solution. The top of the liquid container 2 is 30-60 mm, and the numerical control computer 7 adjusts the coordinate position of the nozzle 1 on the numerical control polishing machine tool 6, so that the distance between the outlet of the nozzle 1 and a certain polishing point on the surface of the workpiece is controlled within 5 times to 6 mm of the outlet diameter of the nozzle 1 about times;

[0027] Step S2: inject the polishing liquid into the polishing liquid container 2 until the polishing liquid container 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com