Vehicle frontal collision finite element model rapid-matching method

A finite element and model technology, applied in the field of automotive computer-aided design, can solve problems such as broken or continuous, the time may be from 0 mm to the late stage of collision, long test period, long simulation calculation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

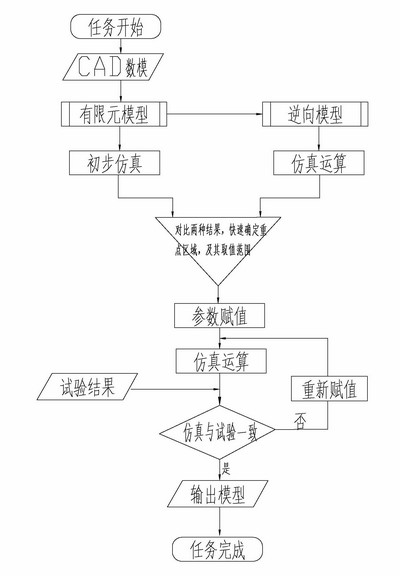

[0038] according to figure 1 As shown, taking the establishment and matching of a 56-kilometer frontal collision model of a certain vehicle as an example, the method for quickly matching the vehicle frontal collision finite element model of the present invention includes the following steps:

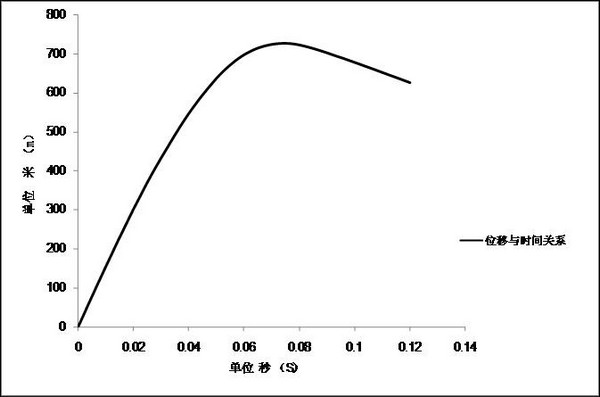

[0039] Step 1. Obtain collision data, CAD digital model and related parameters: Carry out a frontal collision of the benchmark car, obtain the collapse distance and time curve of the benchmark car during the collision process, frontal collision test data, vehicle CAD digital model, and obtain various parameters of the benchmark car at the same time;

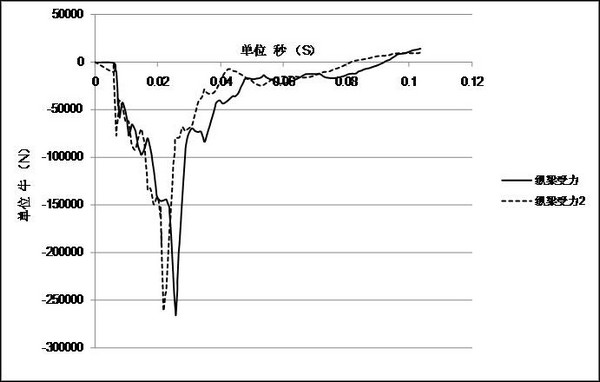

[0040] According to GB 11551-2003 or FMVSS 208 and other standards, the frontal collision of the benchmark car is carried out to obtain the frontal collision test data of the benchmark car, mainly the acceleration curve of the driver's side body, which is fixed at the lower end of the B-pillar or the rear Accelerometer acquisition near th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com