Tubular metal membrane bioreactor

A bioreactor, metal membrane technology, applied in sustainable biological treatment, permeation/dialysis water/sewage treatment, aerobic process treatment, etc. , membrane materials are easily deformed, etc., to achieve the effects of stable chemical properties, simple and thorough cleaning, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The implementation steps of the inventive method are described in detail below according to the accompanying drawings:

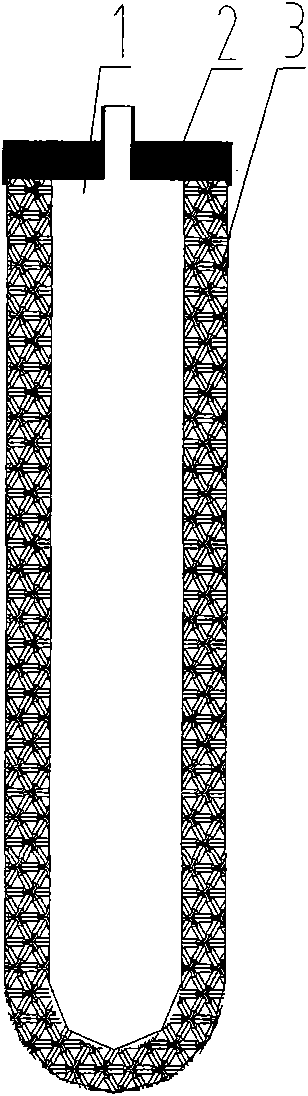

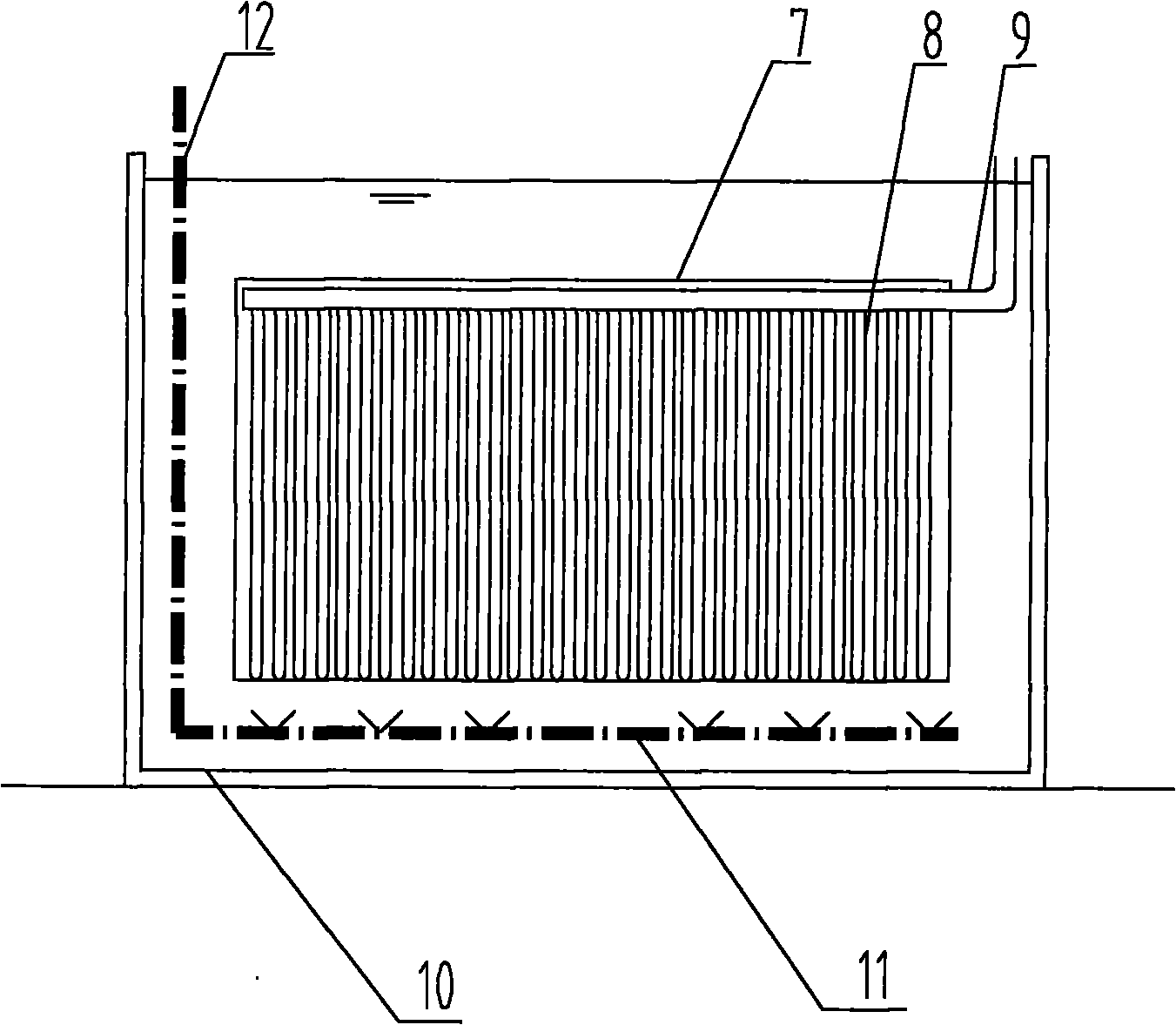

[0014] Such as figure 1 and figure 2 As shown, the tubular metal membrane element used in the membrane bioreactor process of the present invention includes an inner cavity 1 , a head 2 and a metal filter layer 3 . The metal filter layer 3 is a filter membrane with a surface pore size of 0.1-100 μm, which is sintered from metal materials. One end of the tubular metal membrane is closed, and the other end is connected to the water outlet pipe 4 through the head 2, the elbow 6 and the union joint 5, and the water outlet pipe 4 is connected to the water outlet main pipe 9 of the membrane module. The entire metal membrane originals can be arranged singly or several side by side, and installed inside the membrane box 7 to form a membrane module. Such as image 3 As shown, the lower part of the membrane module is laid with a perforated aeration pipe 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com