Lower buffer structure for display panel, package buffer structure and package manufacture method

A technology of display panel and buffer structure, applied in packaging, transportation and packaging, packaging of fragile items, etc., can solve the problems of high price of buffer structure, increase production process, affect product export, etc., and save unit packaging consumption and transportation. Cost, the effect of saving packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

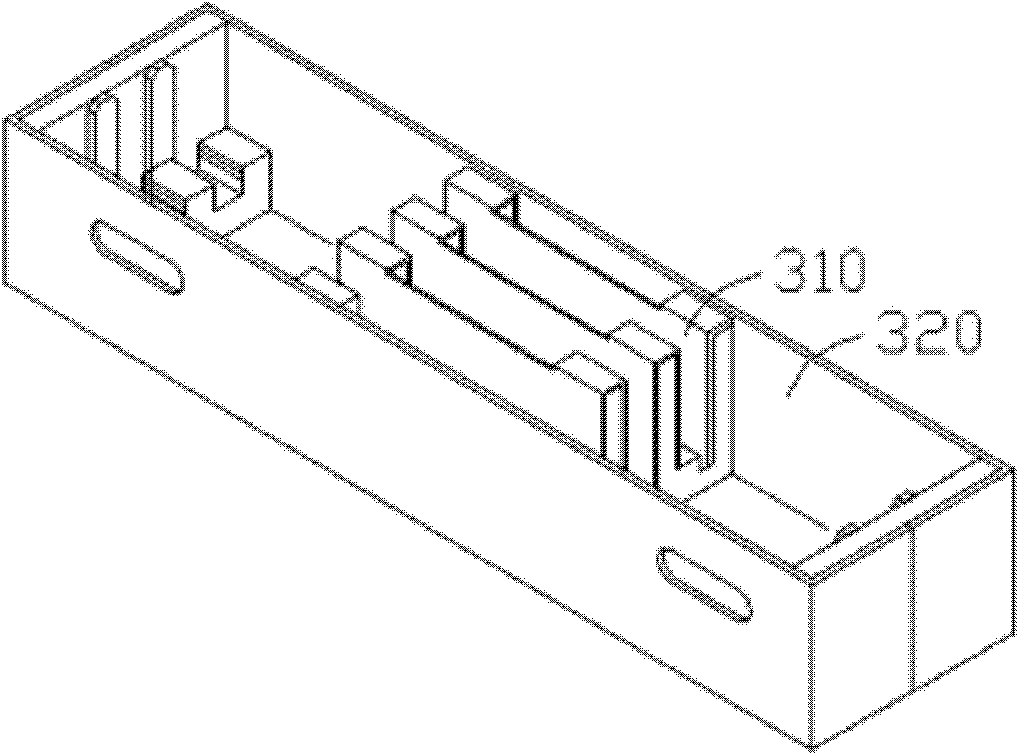

[0032] refer to Figure 6, an embodiment of the lower buffer structure used in the display panel of the present invention includes:

[0033] The carrying frame 610 includes a bottom plate 611, and further includes a first side plate 612 and a second side plate 613 respectively extending upward from two opposite sides of the bottom plate 611;

[0034] The two first buffer bodies 620 are respectively arranged at the junction of the first side plate 612 and the bottom plate 611 of the bearing frame 610, and at the junction of the second side plate 613 and the bottom plate 611;

[0035] The two second buffer bodies 630 are respectively arranged on the inner wall of the first side plate 612 and the inner wall of the second side plate 613 of the bearing frame 610, and the second buffer body 630 is located above the first buffer body 620;

[0036] in,

[0037] The inner wall of the first buffer body 620 is provided with a row of vertical first grooves 621 arranged at intervals hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com